Anode Answers for Hard Chrome Plating

While problems continue to rise with using lead anodes for hard chrome plating, some manufacturers are discovering platinized titanium anodes as a much-improved alternative with a long list of advantages.

Share

Read Next

The customized and dimensionally stable Platinode achieves high-quality coating results.The platinized titanium or niobium electrodes enable a uniform coating thickness distribution on the workpiece, which does not require any postprocessing. Added to this is a long service life. All photos courtesy of Umicore Metal Deposition Solutions

The use of platinized titanium or niobium anodes in hard chrome plating has many benefits over its counterpart, lead anodes. According to Umicore Metal Deposition Solutions, a manufacturer of platinized titanium anodes, this product not only results in a more uniform and higher quality deposition but also significantly reduces investment costs compared to using lead anodes and without any additional effort from the user. Energy savings, higher quality and longer service life are some other advantages. Looming lead-processing regulations is another argument to replace lead anodes with platinized titanium anodes.

Specially developed for hard chrome processes, Platinode HC, platinized titanium or niobium anode from Umicore, is designed using high-quality electrocatalytic coating processes (high-temperature electrolysis). Because the product is more environmentally friendly, it is classified for government subsidies in Germany. The company offers the application for the subsidy as a free service and is working to offer this service in all other relevant European countries.

High quality coating

With Platinode HC’s tailor-made electrodes, high-quality coating results are achieved, according to the company. Its design enables a uniform coating thickness on the workpiece, which does not require any postprocessing

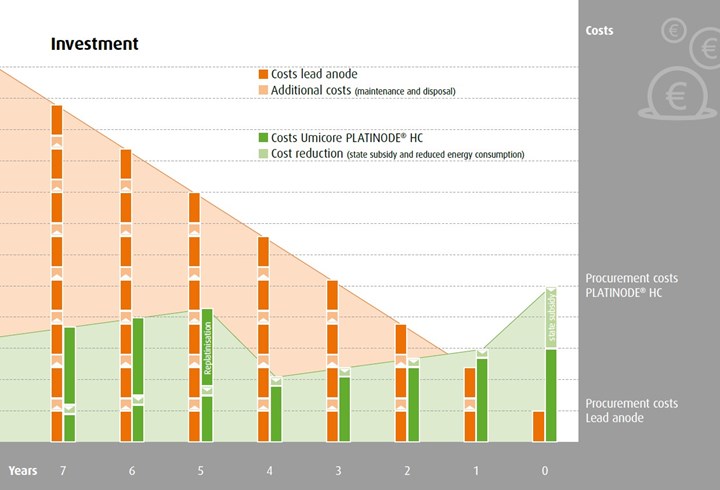

The investment in the Platinode HC pays for itself in the second year because of the government subsidy, the energy savings and the elimination of lead chromate disposal. The reusability of the individually manufactured electrode design, which can simply be replatinated after an average of five years when the platinum layer wears off, has a positive effect on the overall calculation.

because of the dimensional stability of platinized titanium anodes and the high-temperature electrolysis (better than aqueous deposition). The high-temperature electrolysis enables a 99.99% pure platinum layer as well as high adhesive strength and ductility.

The Umicore product in all versions has a high adhesive strength, corrosion resistance and ductility and thus an above average service life. According to the company, it has about five times the service life than that of a commercial lead anode. The investment pays for itself after about three years, but in the case of energy-intensive hard chrome plating, return on investment (ROI) would be likely in the second year because of the possible government subsidy, the energy savings and the elimination of lead chromate disposal.

The engineering firm, Delta Engineering and Chemistry GmbH, has investigated and performed a comparative analysis of Platinode HC and lead anodes in terms of energy efficiency and savings in laboratory conditions. It was found that a 1-to-1 replacement of lead anodes by the platinized titanium anode produced energy savings of at least 2.7% because of improved electricity conduction of the platinum coating.

Factors that are more difficult to measure, such as a more efficient workflow, the reduction of maintenance measures and the resulting production downtimes are other considerations. The same goes for the reusability of the customized electrode design, which can simply be replatinated after the platinum layer wears out. ROI does not include the cost and time incurred by official requirements for lead anodes.

Lead-processing regulations

These benefits, paired with problematic use of lead anodes in hard chrome plating for suppliers, makes platinized titanium anodes a more desirable choice. In fact, the lead chromate produced during hard chrome plating is

Hard chromium plating with lead anodes produces lead chromate, which is highly hazardous to water, carcinogenic and toxic to reproduction. Reducing the distance between anode and cathode and thus saving energy is not possible with conventional lead anodes due to deformation.

classified in Germany as “highly hazardous to water” (the highest possible classification) and can even trigger natural disasters. In addition, the waste product is classified as carcinogenic and toxic to reproduction. The European Chemicals Agency has included lead chromate in the candidate list of Substances of Very High Concern.

These and other assessments are leading to increasing regulations of lead-processing companies worldwide. There are already time-consuming and costly hurdles in the procurement of lead for further processing, for example, through registration with the U.S. Environmental Protection Agency (EPA). Conversely, there are often numerous obstacles in the disposal of waste —quantitative levy regulations or the associated costs. The procurement of lead and the disposal of the resulting waste products such as lead chromate sludge is likely to become increasingly complicated and expensive until a possible ban.

Also, because of health hazards, stricter regulations are also becoming important to occupational safety, as can be seen from the reaction of the U.S. Occupational Health and Safety Association (OSHA). The requirements for the protection of employees (cleaning equipment, protective clothing, medical check-ups and so on) are becoming more extensive and thus more costly. The long-term goal of all measures is to eliminate lead from industrial processes through concerted global efforts.

Conditions for subsidies

Because Platinode HC avoids carbon dioxide emissions due to the lower electricity demand compared to lead anodes, as much as 40% of the investment in the product can be subsidized in Germany by the Federal Office for Economic Affairs and Export Control (BAFA). This includes a maximum of 300,000 euros over a period of three years. Corporate groups can reduce their investment by 700 euros and small and medium-sized companies by 900 euros per metric ton of carbon dioxide.

The fact that Umicore mediates the application process without additional costs saves the time of applying for the subsidy, saves mediation of an independent energy consultant to submit the subsidy application, and saves time, energy and costs that are necessary when using a verification procedure for carbon dioxide savings confirmation.

Related Content

Products Finishing Reveals 2023 Qualifying Top Shops

Each year PF conducts its Top Shops Benchmarking Survey, offering shops a tool to better understand their overall performance in the industry. The program also recognizes shops that meet a set of criteria to qualify as Top Shops.

Read MoreAdvantages to Pumped Eductor Agitation

Not all agitation methods are created equally. Pumped agitation with eductor nozzles can improve process tanks and quickly show a reduction in operating costs while keeping staff safe, following environmental legislation and preventing pollution.

Read MoreLiquid Chrome Vs. Chromic Acid Flake

Contemplating how to continue offering chromic acid services in an increasingly stringent regulatory world? Liquid chrome products may be the solution you’re looking for.

Read More3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.

Read MoreRead Next

A Chromium Plating Overview

An overview of decorative and hard chromium electroplating processes.

Read MoreMasking Solutions for Medical Applications

According to Custom Fabricating and Supplies, a cleanroom is ideal for converting, die cutting, laminating, slitting, packaging and assembly of medical-grade products.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More