Choosing the Right Powder Booth Technology

Is your powder coating operation experiencing an increasing number of color change requirements? Nicolas Gervaise of Carlisle Fluid Technologies discusses fast color change single booth configurations for powder coating.

Q: We currently have two dedicated cartridge reclaim booths for high-volume colors and a third booth where we spray to waste all other colors. The system has suited us well for many years; however, we have seen a shift in demand and are now spraying more “other” colors. Our marketing team tells us the trend will continue. What are the options for improving our process? We do not want to continue spraying to waste as the cost is becoming considerable.

A: Many manufacturers have faced the same challenge you have described. Your original systems were once very efficient regarding powder utilization and color change time — two key drivers. As trends have changed regarding the demand for custom colors or the desire to manufacture to order/just in time, the need for more flexibility in the powder coating process has developed. To address this, fast color change single booth configurations are available. Note that “fast” is a relative term. A color change can typically be accomplished in 8–10 minutes for a single powder booth configuration. Now, this may be longer than your current process with dedicated booths; however, there are many benefits to the most recently designed systems.

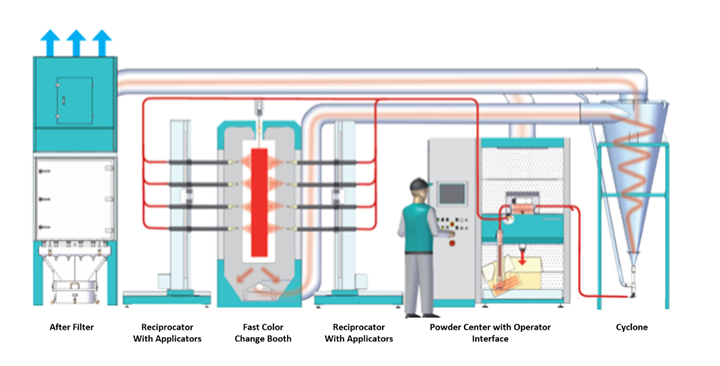

The primary benefit is the ability to change colors efficiently; the system is designed specifically for this purpose. The booth is a non-metallic design with an air space in the walls; while in use, the walls will repel the powder allowing it to flow into the recovery system. The booth is connected to a cyclone separator through seamless ductwork, minimizing areas where the powder can accumulate. The cyclone separates the fine particles from the larger particles, which fall to the bottom of the cone. Airflow through the system is created by the after filter, which collects the fine particles that rise up in the cyclone. Air from the after filter is exhausted back into the powder coating area.

The powder center offers a central location for the operator to control the system and manage powder delivery and color changes. A powder box is placed on the vibrator table, and a transfer pump is lowered into the box. The transfer pump fills the fluidized hopper, equipped with an ultrasonic sieve that removes any contaminants in the powder. The fluidized hopper feeds individual venturi pumps for each manual or automatic applicator in the system. Additionally, the powder collected in the cyclone is fed back into the hopper and sieved. The reclaim powder is continually blended in the hopper with virgin powder, providing a better overall finish than your older system, where reclaim had to be collected and manually brought back into the process. The design of the system allows for up to 97% reclaim efficiency.

When it is time to change colors, the operator empties the powder from the hopper back into the box and then enters color change mode. The booth exit door closes, and the damper in the bottom of the booth that regulates airflow opens fully, allowing for maximum airflow through the booth and the powder center. The operator then uses an air lance to blow down the booth and equipment before loading the next color into the system.

Modern powder booths are designed to accommodate changing market needs for fast color change, high reclaim efficiency, and ease of use for the operator.

About the Author

Nicolas Gervaise

Nicolas Gervaise is global product manager – powder for Carlisle Fluid Technologies. Visit carlisleft.com.

Related Content

How to Choose Between Sulfate and Chloride-Based Trivalent Chromium

There are several factors to consider when choosing between sulfate and chloride-based baths for trivalent chromium plating. Mark Schario of Columbia Chemical discusses the differences and what platers should keep in mind when evaluating options.

Read MoreA Chromium Plating Overview

An overview of decorative and hard chromium electroplating processes.

Read MoreAnodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.

Read MoreZinc Phosphate: Questions and Answers

Our experts share specific questions about zinc phosphate and pretreatment

Read MoreRead Next

12 Ways to Improve Your Powder Coating Quality

Often overlooked powder coating procedures that can help you elevate your quality, streamline your operations and improve your profitability.

Read MoreAdjusting Current and Voltage When Powder Coating

Which manual powder coating gun setting is better to adjust, voltage or current? Jeff Hale of Gema USA discusses when to use different settings on your powder gun to achieve optimal results.

Read MoreThe Powder Coating Process

Powder coating is one of the most durable finishes that can be applied to industrial manufactured products, and offers excellent corrosion protection and is very safe because of its lack of volatile organic compounds. To understand the powder coating process you should start with the fundamentals.

Read More