Q. I am being asked to specify metallic coatings for my company’s fasteners. Can you provide some guidance for selecting a coating?

A. Though it is well known that coatings help with fastener performance by improving durability and lifespan, the importance of choosing the proper coating can often be overlooked. Common coating options for fasteners over a steel substrate include zinc, mechanical zinc, zinc-nickel, zinc-flake, tin-zinc and zinc-iron. Certain factors must be examined when choosing the appropriate coating to specify for your fastener application. It’s always wise to begin with the end in mind. It’s important to research and carefully consider the specific requirements of the fastener in its state of end use in order to determine the coating that will work best. Asking the right questions about factors such as corrosion resistance requirements, durability, temperature, torque tension needs, and more is the place to begin.

Photo Credit: Columbia Chemical

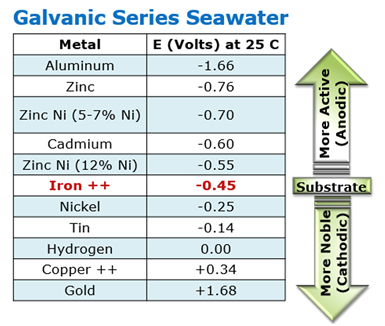

With a strong industry focus on corrosion resistance, let’s start with a popular and helpful tool in considering the metallic layer to coat the steel substrate: the galvanic series seawater table (figure 1). The table provides the galvanic comparison of the various metals over steel, measured by electro potential volts. The farther apart the metals are on the chart, the more dissimilar they are, resulting in a higher potential for corrosion.

Starting at the top of the chart, we have aluminum, which is very active (anodic) compared to iron (our usual substrate) and at the bottom of the slide, we have gold, which is very noble (cathodic) to iron. Coatings that are more active than steel will protect the underlying substrate. These include zinc, cadmium, zinc-nickel and aluminum. Coatings that are more noble than steel will not be sacrificial to steel. These can include nickel, tin and copper.

To further this example, let’s look at iron in the middle, highlighted in red. Directly above it is zinc-nickel 12%. The potential difference from iron to zinc-nickel is only 0.1 in the galvanic seawater series; if you compare that difference to iron/zinc, there is a 0.31 difference. This difference is what drives the corrosion rate of the sacrificial coating and should be one of the factors considered when identifying a coating choice for your fasteners.

The next factors we can delve into are durability and temperature requirements. Will the fastener be subject to abrasion and what temperature will it be exposed to? (For the purposes of walking through these examples, we are going to key in on zinc-nickel).

Zinc-Nickel has increasingly become the finish of choice for many industries with high corrosion and high-performance needs. From a durability standpoint, zinc-nickel has a Vickers Hardness of 400 to 500 HV (compared to a zinc-only deposit, which is approximately 100 HV). Because handling and assembly can be a destructive process for softer coatings like zinc and zinc flake, the combination of hardness and overall corrosion protection make the zinc-nickel alloy deposit ideal for fasteners or components that require further handling or assembly.

Another excellent benefit of the zinc-nickel alloy deposit is its overall resistance to heat. If your spec requires baking, the zinc-nickel deposit can withstand bake temperatures in excess of 200°C for four hours and still achieve 800 hours of neutral salt spray protection to first red rust. Zinc-nickel is commonly used on stampings and fasteners for barrel applications and heavily used on brake component castings in rack applications. Alkaline and acid zinc nickel offer different performance benefits that are suited to specific applications, so be sure to work with a knowledgeable chemistry supplier to select the appropriate process to meet your needs.

Hydrogen embrittlement is a primary concern for fastener manufacturers. Fasteners with Core Hardness over 39 HRC are susceptible to embrittlement from hydrogen. Fastener coatings should be selected to minimize risk, where coating risk is high, process should be validated that parts have not been embrittled. The porosity in the electroplated coating is a first order effect on hydrogen embrittlement. Porosity allows the hydrogen to escape after processing. Zinc-nickel often lends itself well to this application since it is microcracked and allows entrapped hydrogen to escape through the porosity of the coating.

Finally, let’s look at considerations related to passivate needs and torque tension. Trivalent passivates (conversion coatings) provide protection from white corrosion products and extend hours to red base metal corrosion. They can address appearance factors needed as they provide colors ranging from clear to blue to iridescent to black. The thickness of the passivate can determine the color with a general rule of thumb being 1 nanometer of thickness provides one hour to first white rust. Sealers can be added on top of the passivate layer to provide additional salt spray, provide gloss when needed, and can provide some lubricity.

After fasteners are plated and then passivated for color and corrosion, a lubricant can be applied to provide proper torque tension relationships. Understandably, fastener manufacturers are concerned about torque tension because if parts are insufficiently tightened, the bolts will come loose, and if parts are over-tightened, the bolts could break. The bolts must be stretched and stay stretched at the right levels to avoid failure.

More and more fastener coatings are being required to fulfill specified tightening characteristic requirements with the use of an automatic machine to perform the tightening, at a specified speed and to specified torques. The torque tension testing equipment tests the integrity of the finished fasteners, ensuring they will tighten consistently without breakage or vibration. Specialized testing equipment has the capability to determine torque and angle, clamping force, head friction, yield point, fracture breaking and other parameters. It also allows the calculation of the coefficient of friction, which provides a more detailed analysis of the torque and tension relationship. This information is critical to OEMs and manufacturers with regard to safety limits.

There are additional factors a materials and coatings engineer, or OEM will take into consideration, such as cost, size, etc., but corrosion resistance, durability, temperature, and torque tension needs are some of the initial factors to be considered when identifying a coating for fasteners.

About the Author

Mark Schario

Executive Vice President for Columbia Chemical. Visit columbiachemical.com.

Related Content

Zinc Phosphate: Questions and Answers

Our experts share specific questions about zinc phosphate and pretreatment

Read MoreAn Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

Read MoreUnderstanding and Managing White Spots on Anodized Aluminum

Having trouble with spotting defects when anodizing? Taj Patel of Techevon LLC offers a helpful overview of the various causes of white spots and potential solutions.

Read MoreHow to Maximize Nickel Plating Performance

The advantages of boric acid-free nickel plating include allowing manufacturers who utilize nickel plating to keep up the ever-changing regulatory policies and support sustainability efforts.

Read MoreRead Next

Achieving Coefficient of Friction Targets

Jennifer Geesey of Pavco Inc. offers advice for obtaining your desired coefficient of friction.

Read MoreCoping With Staffing Shortages

Tom Mastalerz, business development manager at Columbia Chemical, discusses strategies for optimizing operational efficiencies to help combat staffing shortages.

Read MoreDisruptive Change: EVs and Finishing Opportunities

As EVs continue to claim an increasingly larger share of the automotive market, what can finishers expect in terms of demand for finishes? Mark Schario of Columbia Chemical shares his insights into the kinds of opportunities EVs present for finishers.

Read More