Top Shop Savors Past 20 Years of Prosperity

This one-stop finishing shop was rescued by new management in 2004. Since then, its rejuvenation has brought substantial growth and success to the business.

Fred Carlson started ATG in 1931 after there was a falling out between he and his partner at another local plating shop. “He then walked a couple blocks east, rented a warehouse and started his own business,” says Robin Scheppner, Carlson’s granddaughter. “He named it American to put it first in the phonebook.” Photo Credits: American Tinning and Galvanizing

Sometimes all it takes is a change of perspective in order to turn a negative situation into a positive one. Robin Scheppner experienced this when she took over her family’s business, American Tinning and Galvanizing (ATG), in Erie, Pennsylvania. She built a new culture that changed the company’s morale and, in turn, improved sales and quality.

As a result of refocusing company culture to concentrate on mutual respect, morale has greatly improved as well as the production quality and increased number of employees and the attitude and atmosphere of the shop, Scheppner says. In 2004 the company employed 42 people and now that number is over 80 staff members who care about the quality of products that leave the facility.

“VP of Operations Rodney Chiarelli preached a ‘quality brings quantity’ mantra,” Scheppner says. “Making quality the priority over speed gave us a leg up in customer satisfaction and retention. ATG has since enjoyed double digit growth for the past 19 years.”

Turning a new leaf

Fred Carlson, Scheppner’s grandfather, started ATG in 1931 after there was a falling out between he and his partner at another local plating shop. “He then walked a couple blocks east, rented a warehouse and started his own business,” she says. “He named it American to put it first in the phonebook.”

Beginning as a tinning business, ATG expanded its metal finishing capabilities through the years. In 1955, Fred and Harry Carlson established Carlson Erie Corp., which was a fabricator of tanks and racks for ATG and other metal finishers. Carlson’s son-in-law, Jack Scheppner, managed Carlson Erie Corp., and in the late 1970s, took over both companies. It was during this era that ATG added a number of processes to its metal finishing menu. In addition to galvanizing, anodizing (chromic and sulfuric), alodine, zinc and cadmium electroplating and oxide treatments were introduced. The customer base expanded with the variety of services and both the reputation, and the bottom line grew. Upon Mr. Scheppner’s retirement, the company leadership was passed on to his daughter, Kathleen. There were some setbacks and times turned hard for the family-owned business.

In 2004, after Kathleen retired, Robin Scheppner returned to her hometown to take the reins. Determined to rebuild her family’s legacy and regain prosperity, she led the management team in building a new strategic plan to

As a NADCAP (National Aerospace and Defense Contractors Accreditation Program)-certified supplier, ATG has been the leader in the corrosion control of metal since 1931 through the use of high-quality chemical processing systems. With a quick turnaround rate, most jobs are in ATG’s building for only 48 hours.

revitalize the struggling enterprise. The team made a pact with all the employees, stating either they would hold hands and go forward together or shake hands and close the door. Because more than 50% of the employees at the time had more than 20 years of experience, it was imperative for the company to regain its solvency and reputation. Therefore, improving company culture was the first priority.

“It then became a focus of ours to get our customers back and regenerate the production levels that this company was capable of,” she says.

The NADCAP building blocks

By concentrating on quality and customer service, ATG has re-established itself. Earning NADCAP certification has been a major building block to the company’s success because it opened the door to a larger customer base within the aerospace finishing industry.

During her first year as president, ATG was audited for this aerospace

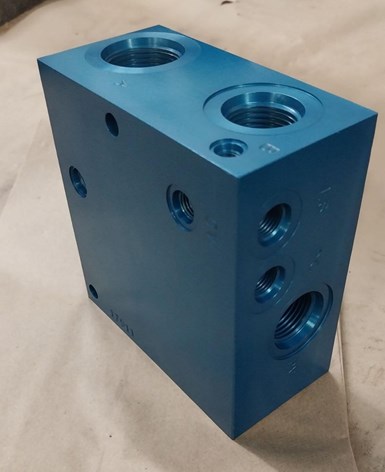

Through the years, ATG has gradually become a one-stop shop for its customers. Now, the company provides hot dip galvanizing, zinc and cadmium electroplating, chromic and sulfuric acid anodizing, chromate conversion and alodine, and fabricating. It also offers specialized post-processing services on materials that require re-machining or re-chasing after finishing has been completed.

certification but was unsuccessful. However, not willing to take no for an answer, the quality management team at ATG petitioned for a second chance, and it worked. Since then, the shop has had successful audits every year.

Many of those audits ATG passed with merit. “I know that’s supposed to be an accolade, but I tend to look at it a little negatively,” Scheppner continues. “I think if we don’t have that annual intervention and review, we tend to get a little too complacent. I’m all for spending the money for the audit because it keeps us on our toes, and we get better every year.”

Because it is a NADCAP shop, it has had many business opportunities beyond the company’s 300-mile radius, where most of its customers dwell. To date, the shop has done business in 30 to 35 states, according to David Bertges, VP of finance and human resources.

With more than 500 customers, ATG does not only service the currently busy aerospace market. Chiarelli explains that the military segment makes up a lot of its customers. It also serves the solar panel industry as well as electronics and automotive. ATG is even doing work for Walmart, Lowe’s and Amazon.

Longevity is a characteristic of its customer base as well. “We have a lot of customers who have been with us for 35 to 40 years,” Bertges says.

Expanding service offerings

With an array of finishing capabilities, it is easy for ATG customers to receive the services they demand, which is important to Scheppner and her staff. In fact, she believes the company’s superb customer service is what makes it stand out against its competitors.

“We really have a master’s degree in products finishing and turn out a very good product with very good customer service,” she says.

ATG employees give back to their community. Scheppner motivates her staff by offering one hour of paid time off for every hour an employee volunteers within the community. They can earn up to four days a year, one per quarter.

Through the years, ATG has gradually become a one-stop shop for its customers. Now, the company provides hot dip galvanizing, zinc and cadmium electroplating, chromic and sulfuric acid anodizing, chromate conversion and alodine, and fabricating. It also offers specialized post-processing services on materials that require re-machining or re-chasing after finishing has been completed. The shop’s No. 5 turret lathes equipped with air chucks can turn up to a 19-inch diameter part.

Giving back

While quality and customer service are two aspects of the business ATG excels at, the company strives to nurture a culture of community service and support. Besides being generous in its philanthropy of local initiatives for community schools, the homeless and the hungry, the company also rewards its employees for their community service hours.

Scheppner explains that for every hour an employee volunteers within the community, they can get one hour of paid time off. They can earn up to four days a year, one per quarter.

She adds, “Our employees demonstrate the ‘give back’ attitude; we have 100% participation in Erie’s United Way. As a company, we use the PA EITC (Earned Income Tax Credits) tax credits to sponsor early childhood development programs throughout the city.”

ATG also participates in Adopt-A-Highway, local blood drives and United Way’s National Night Out. And, finally, for the past decade, ATG has displayed a mural on the face of its building on one of Erie’s busiest corners. The themes are always positive, highlighting a local festival, honoring military services, or touting Erie’s rich manufacturing history.

Related Content

The Best Method for Coating Full-Size Aircraft

John Owed from Carlisle Fluid Technologies analyzes the difference between using air-assisted airless, air spray and other technologies for coating a full-size aircraft. Which is better?

Read MoreAnodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.

Read MoreVST Appoints Marketing and Communications Director

Julie Sims has been named as Valence Surface Technologies' marketing and communications director.

Read MoreA Smooth Transition from One Anodizing Process to Another

Knowing when to switch from chromic acid anodizing to thin film sulfuric acid anodizing is important. Learn about why the change should be considered and the challenges in doing so.

Read MoreRead Next

Expanding Custom Work Enables Top Shop to Shine

This six-person shop rallies together to offer diverse finishing jobs that are growing to include custom show parts for automobiles and motorcycles.

Read MoreSmall Staff Operates Lucrative Powder Coating Top Shop

Strength in numbers? Not necessarily. Determination, customer loyalty and family values have held up this small family-owned shop after almost 30 years in business, including surviving a natural disaster.

Read MoreNADCAP Shop Digitizes to Eliminate Paper Trail

Customizable ERP software has transformed a 27-year-old manual metal finishing job shop into a state-of-the-art paperless company with full digital traceability in about 10 months.

Read More