NASF/AESF Foundation Research Project #121: Development of a Sustainability Metrics System and a Technical Solution Method for Sustainable Metal Finishing - 8th Quarterly Report

This NASF-AESF Foundation research project report covers the eighth quarter of project work (January-March 2022) at Wayne State University in Detroit. The major activities in this report period are: (1) the development of a sustainability assessment method for technology evaluation with case studies, and (2) a continuous development of a software tool for sustainability assessment.

by

Yinlun Huang*

Department of Chemical Engineering and Materials Science

Wayne State University

Detroit, Michigan, USA

Editor’s Note: This NASF-AESF Foundation research project report covers the eighth quarter of project work (January-March 2022) at Wayne State University in Detroit. A printable PDF version of this report is available by clicking HERE.

It is widely recognized in many industries that sustainability is a key driver of innovation. Numerous companies, especially large ones who made sustainability as a goal, are achieving clearly more competitive advantages. The metal finishing industry, however, is clearly behind others in response to the challenging needs for sustainable development.

This research project aims to:

- Create a metal-finishing-specific sustainability metrics system, which will contain sets of indicators for measuring economic, environmental and social sustainability,

- Develop a general and effective method for systematic sustainability assessment of any metal finishing facility that could have multiple production lines, and for estimating the capacities of technologies for sustainability performance improvement,

- Develop a sustainability-oriented strategy analysis method that can be used to analyze sustainability assessment results, identify and rank weaknesses in the economic, environmental, and social categories, and then evaluate technical options for performance improvement and profitability assurance in plants, and

- Introduce the sustainability metrics system and methods for sustainability assessment and strategic analysis to the industry.

This will help metal finishing facilities to conduct a self-managed sustainability assessment as well as identify technical solutions for sustainability performance improvement.

1. Student participation

Abdurrafay Siddiqui, a Ph.D. student, has continued to be guided by the PI to work on the project. In this project reporting period, the student is fully supported by Wayne State University as a Graduate Teaching Assistant (GTA). In addition, he also partially works on the AESF project and the surface finishing relevant part of a National Science Foundation (NSF) project for which Prof. Huang also serves as the PI. In the winter semester (January to April 2022), two undergraduate students, Rebecca Potoff, a senior student of chemistry at SUNY Binghamton University, and Govanni Gjonaj, a senior student of chemical engineering at Wayne State University, were also hired by the PI to be NSF Undergraduate Research Assistants (URA) for the project; they have been financially supported by the PI’s NSF grant.

2. Project activities and progress

The major activities in this report period are: (1) the development of a sustainability assessment method for technology evaluation with case studies, and (2) a continuous development of a software tool for sustainability assessment. Each of these is briefly reported below.

2.1 Technology assessment: Method and case study

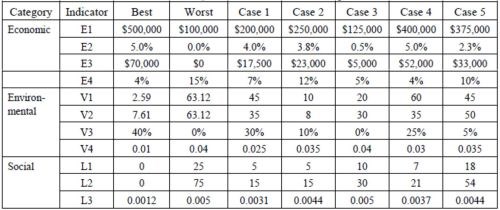

Table 1 - Original indicator data for multiple case studies.

In the previous quarterly reports, we described our sustainability metrics system and its classification, as well as a sustainability assessment method using the metrics system. We also identified five cases representing five plants and used a small set of the sustainability metrics system to evaluate the sustainability performance of each plant. Table 1 shows the data used for the assessment, where the sustainability indicators included are: (a) in the Economic sustainability category: E-1: Value Added, E-2: Net Profit Margin, E-3: Investment in New Technology, and E-4: Product Defect Rate; (b) in the Environmental sustainability category: V-1: Fresh Water Use, V-2: Wastewater Generated, V-3: Water Recycled and V-4: Hazardous Waste Generated and (c) in the Social sustainability category: L-1: Complaints from the Local Community, L-2: Complaints from Customers and V-3: Human Health Burden.

In addition to the assessment, we also reported our detailed analysis of the plant performance and identified some improvement areas in the previous report.

2.1.1 Selected technologies. In this quarter, we identified two technologies that were developed by Prof. Huang’s group previously.1,2

- Tech 1: The Chemical Concentration Optimization (CCO) Technology. The key components of the technology are: (a) a first principles-based dynamic model for cleaning units performing alkaline, acid, or electro-cleaning operations, and (b) an optimal operation strategy for determining optimal chemical settings in different cleaning units. This CCO technology can help reduce chemical consumption, lower chemical loss to the succeeding rinsing units, and thus lower the chemical concentration in wastewater, while the cleaning quality can always be guaranteed.

- Tech 2 – The Optimal Water Use and Reuse (OWUR) Technology. This technology was developed using system modeling and optimization techniques. A fundamental rinsing system model could provide necessary information for redesigning a rinsing system if necessary, and for determining an optimal setting of each freshwater flow and for guiding water reuse before being discharged to a wastewater pretreatment facility in a plant. This technology could significantly reduce the consumption of freshwater and the volume of wastewater, and lower wastewater treatment cost, while the rinsing quality in different operational steps can be ensured.

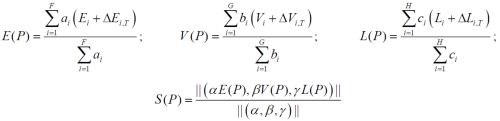

2.1.2 Technology assessment method. The following formulas were reported in the 7th progress report.

They are used to evaluate each technology under assessment.

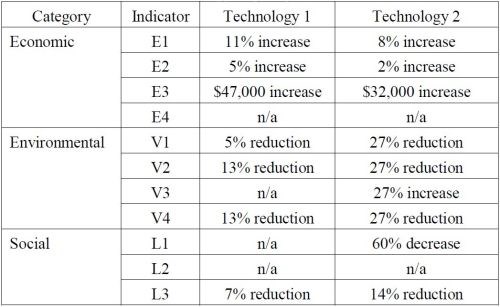

2.1.3 Technology capacity evaluation. The sustainability indicators used for process performance

assessment, which are shown in Table 1, are adopted to evaluate the two technologies. Each technology’s

capacity using these indicators is summarized in Table 2, where the indicator-based technology capability

is represented as a percentage, except for the technology investment.

Table 2 - Technology capacity evaluation data.

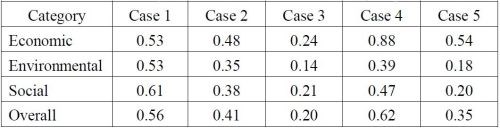

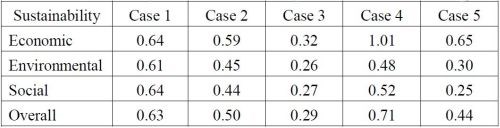

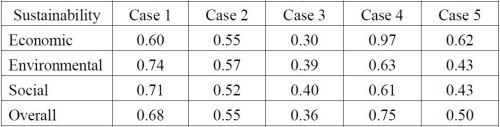

2.1.4 Technology application benefits summary. Using the technology capacity data in Table 2, we conducted sustainability performance assessment using each individual technology. Table 3 shows the sustainability performance of each plant before using any of the two technologies, while Tables 4 and 5 provide the results after implementing each technology.

Table 3 - Sustainability Performance before Technology Implementation.

Table 4 - Sustainability Performance after Implementation of Technology 1.

Table 5 - Sustainability Performance after Implementation of Technology 2.

2.1.5 Basic analysis. The assessment results in Tables 4 and 5 show that overall, Tech 2 is more capable than Tech 1 when the sustainability improvement focus is on both environmental and social sustainability. The average increase of the environmental sustainability by Tech 2 is above 98% as opposed to Tech 1, which shows an average increase of 44%. However, if the economic sustainability is a focus, then Tech 1 is better, which demonstrates an average increase of 23% as opposed to Tech 2 (16%). Since the technologies have different technical functions, companies can decide which technology should be adopted, based on their own sustainability improvement goals. For instance (referring to the plants analyzed in the 7th quarter report, indexed in Section 4 below), Plant 3 (i.e., Case 3) has the lowest sustainability among five plants, with the lowest profit margins and the worst environmental rating, before adopting any new technology. However, if the plant implements Tech 2, its sustainability performance will be improved to the level similar to Plants 2 and 5 if these two plants do not implement new technologies. As a matter of fact, Plant 3 using Tech 2 has a higher sustainability performance level than Plant 5 with no new technology implemented. This shows that Tech 2 can be a stepping stone towards lowering environmental problems and increasing economic sustainability and social wellbeing.

2.1.6 Paper contribution. The Ph.D. student working on this project submitted a paper on technology assessment for presentation at the 2022 SURFIN Conference in Rosemont, Illinois, in June 2022. The paper title is listed in the reference section.

2.2 ISAE Tool development progress

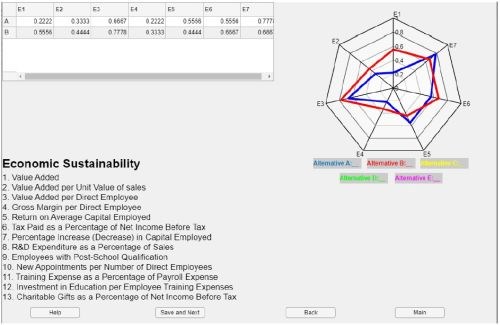

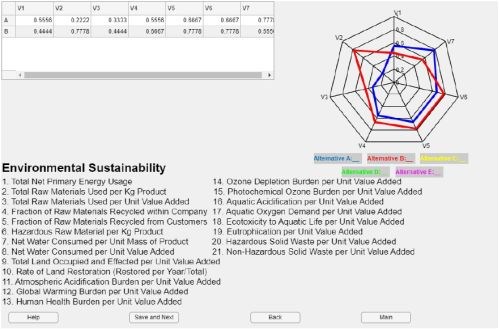

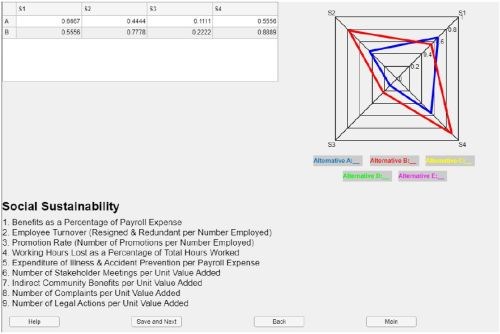

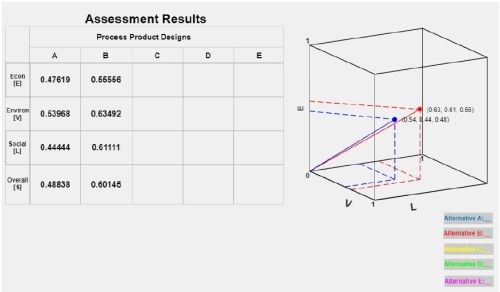

We have made continuing progress on tool development. In this reporting period, we completed the analysis section of the tool. The tool can now accept the user’s selection of sustainability indicators, input of indicator values and the associated weighing factor values and can automatically complete calculations and show assessment results. Figures 1 to 3 show the tool’s capability of plotting sustainability category-based performance of two cases using the radar chart representation scheme. Figure 4 depicts a sustainability-cube-based overall sustainability performance comparison of two cases.

Figure 1 - Economic sustainability indicators and spider chart.

Figure 2 - Environmental sustainability indicators and spider chart.

Figure 3 - Social sustainability indicators and spider chart.

Figure 4 - Sustainability cube for two cases

2.3 References

1. Q. Zhou and Y. Huang, "Hierarchical Optimization of Cleaning and Rinsing," Plating and Surface Finishing, 89 (4), 68-71 (2002).

2. Q. Zhou, H. H. Lou and Y. Huang, "Design of a Switchable Water Allocation Network Based on Process Dynamics," Industrial and Engineering Chemistry Research, 40 (22), 4866-4873 (2001).

3. A. Siddiqui, R. Potoff and Y. Huang, “Technology Assessment for Sustainability Performance Improvement of Metal Finishing Facilities,” to be presented at the 2022 SUR-FIN Conference, Rosemont, IL, June 7-9, 2022.

3. Plan for the 9th quarter of the project

Three tasks are planned for the next project period:

- We will identify additional technologies for technology assessment and conduct additional case studies.

- We will continue to develop the ISAE tool.

- We plan to develop a technical paper for journal publication.

4. Past project reports

1. Quarter 1 (April-June 2020): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 84 (12), 14 (September 2020); Full paper: http://short.pfonline.com/NASF20Sep1

2. Quarter 2 (July-September 2020): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 85 (3), 13 (December 2020); Full paper: http://short.pfonline.com/NASF20Dec1

3. Quarter 3 (October-December 2020): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 85 (7), 9 (April 2021); Full paper: http://short.pfonline.com/NASF21Apr1.

4. Quarter 4 (January-March 2021): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 85 (11), 13 (August 2021); Full paper: http://short.pfonline.com/NASF21Aug1.

5. Quarter 5 (April-June 2021): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 86 (1), 19 (October 2021); Full paper: http://short.pfonline.com/NASF21Oct2

6. Quarter 6 (July-September 2021): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 86 (4), 19 (January 2022); Full paper: http://short.pfonline.com/NASF22Jan3

7. Quarter 7 (October-December 2021): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 86 (7), 17 (April 2022); Full paper: http://short.pfonline.com/NASF22Apr2

5. About the Principal Investigator

Dr. Yinlun Huang is a Professor at Wayne State University (Detroit, Michigan) in the Department of Chemical Engineering and Materials Science. He is Director of the Laboratory for Multiscale Complex Systems Science and Engineering, the Chemical Engineering and Materials Science Graduate Programs and the Sustainable Engineering Graduate Certificate Program, in the College of Engineering. He has ably mentored many students, both Graduate and Undergraduate, during his work at Wayne State.

He holds a Bachelor of Science degree (1982) from Zhejiang University (Hangzhou, Zhejiang Province, China), and M.S. (1988) and Ph.D. (1992) degrees from Kansas State University (Manhattan, Kansas). He then joined the University of Texas at Austin as a postdoctoral research fellow (1992). In 1993, he joined Wayne State University as Assistant Professor, eventually becoming Full Professor from 2002 to the present. He has authored or co-authored over 220 publications since 1988, a number of which have been the recipient of awards over the years.

His research interests include multiscale complex systems; sustainability science; integrated material, product and process design and manufacturing; computational multifunctional nano-material development and manufacturing; and multiscale information processing and computational methods.

He has served in many editorial capacities on various journals, as Co-Editor of the ASTM Journal of Smart and Sustainable Manufacturing Systems, Associate Editor of Frontiers in Chemical Engineering, Guest Editor or member of the Editorial Board, including the ACS Sustainable Chemistry and Engineering, Chinese Journal of Chemical Engineering, the Journal of Clean Technologies and Environmental Policy, the Journal of Nano Energy and Power Research. In particular, he was a member of the Editorial Board of the AESF-published Journal of Applied Surface Finishing during the years of its publication (2006-2008).

He has served the AESF and NASF in many capacities, including the AESF Board of Directors during the transition period from the AESF to the NASF. He served as Board of Directors liaison to the AESF Research Board and was a member of the AESF Research and Publications Boards, as well as the Pollution Prevention Committee. With the NASF, he served as a member of the Board of Trustees of the AESF Foundation. He has also been active in the American Chemical Society (ACS) and the American Institute of Chemical Engineers (AIChE).

He was the 2013 Recipient of the NASF William Blum Scientific Achievement Award and delivered the William Blum Memorial Lecture at SUR/FIN 2014 in Cleveland, Ohio. He was elected AIChE Fellow in 2014 and NASF Fellow in 2017. He was a Fulbright Scholar in 2008 and has been a Visiting Professor at many institutions, including the Technical University of Berlin and Tsinghua University in China. His many other awards include the AIChE Research Excellence in Sustainable Engineering Award (2010), AIChE Sustainable Engineering Education Award (2016), the Michigan Green Chemistry Governor’s Award (2009) and several awards for teaching and graduate mentoring from Wayne State University, and Wayne State University’s Charles H. Gershenson Distinguished Faculty Fellow Award.

* Dr. Yinlun Huang, Professor

Dept. of Chemical Engineering and Materials Science

Wayne State University

Detroit, MI 48202

Office: (313) 577-3771

E-mail: yhuang@wayne.edu

Related Content

NASF/AESF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications – 4th and 5th Quarter Report

The NASF-AESF Foundation Research Board selected a project on electrodeposition toward developing low-cost and scalable manufacturing processes for hydrogen fuel cells and electrolysis cells for clean transportation and distributed power applications. During the reporting period, efforts were focused on planning the overall project work, with the eventual goal of manufacturing an improved design for a Solid oxide fuel cell anode supported flat tube (SOFC).

Read MoreTin-Zinc Alloy Electroplating and Its Corrosion Behavior

An NASF/AESF Foundation Research Program Retrospective

Read MoreLooking Back: The Columnists

Many industrial/technical journals consist of a well-rounded mixture of technical papers, practical articles about technology and how-to-do-it features, including this one, Products Finishing. In its decades of publication, the AESF/NASF journal, Plating & Surface Finishing also endeavored to meet this need. Among the many features were those of the columnists, recognized experts who had expertise in certain segments of the surface finishing industry. This article contains a sampling of columns published in P&SF over the years, which still retain information of importance even today.

Read MoreNASF, AESF Scholarship Program Accepting Applications

The deadline for applications is Feb. 26, 2023.

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More

.jpg;maxWidth=300;quality=90)