The Year in Review

Products Finishing offers a look back at some of the most noteworthy finishing industry stories from 2021.

As we countdown to the new year, Products Finishing has taken some time to reflect on what 2021 held for those in the finishing industry. The year was one of constant anticipation and hope for things to get better and return to normal after a year of quarantines, working from home and social distancing. While some progress was made with the careful return of tradeshows and networking events, these events were, by necessity, of a much smaller scope than in a normal year.

The ripples felt from the COVID pandemic have touched so many aspects of business from workforce to the supply chain. The ramifications are nowhere near over, yet the world is working to adapt and move forward.

Aerospace production isn’t predicted to return to pre-pandemic levels until 2024. Where does that leave finishing operations in the aerospace supply chain?

Photo Credit: Products Finishing

Aerospace market

One of the most glaring areas where we hang our hopes for this “return to normal” is the commercial aerospace industry. While demand for flights is on the rise, a return to pre-pandemic levels will take time. In the following article from the October 2021 issue, PF talks with aerospace finishers to hear their insights into the return of this market for finishers:

“Surface Finishing and the Aerospace Supply Chain”: https://short.pfonline.com/holdingpatterns

As the COVID pandemic continues, coating suppliers work to navigate raw material shortages and chemical price increases.

Photo Credit: ShutterStock

Supply chain challenges

2021 saw myriad pandemic-related struggles caused by more than a year of disruptions in business as usual. Supply chain issues due to workforce challenges, natural disasters and shipping disruptions have hampered the whole of manufacturing. Throughout the year, PF spoke with materials experts to hear their assessments and advice for navigating the shortages:

“Coatings Industry Navigates Supply Chain Disruption”: short.pfonline.com/powdersupplychain

Podcast: Weathering the Supply Chain Storm, Part 1 - Powder Coating: short.pfonline.com/supplypod1

Podcast: Weathering the Supply Chain Storm, Part 2 - Metal Plating: short.pfonline.com/supplypod2

The Metal Finishers Assn. of California (MFACA) held Legislative Day on June 22-23 to raise awareness of how proposed California Legislature would affect metal platers in the state.

Photo Credit: MFACA

Regulatory battles

Compliance with environmental regulations is a constant concern for finishers. Regulations of such substances as hexavalent chromium are becoming increasingly stringent. This past year, metal finishers in California have been in talks with the California Air Resources Board (CARB) over a proposed phase-out of hexavalent chrome use in the state for both decorative and functional finishing applications. PF covered the topic from a few different points of view in the following stories:

“The Continuing Battle Over Hex Chrome”: short.pfonline.com/hex1

Podcast: Transitioning Hexavalent Chromium to Trivalent, Part 1: short.pfonline.com/hexpod1

Podcast: Transitioning Hexavalent Chromium to Trivalent, Part 2: short.pfonline.com/tripod

Podcast: Considering Hex Chrome Alternatives: short.pfonline.com/hexalt

The Chemical Coaters Association International (CCAI) has been working to ramp up efforts to provide financial support for programs that address both the attraction of new talent and retention of skilled workers through its CCAI Finishing Education Foundation (CCAIFEF) — a 501(c)(3) charitable non-profit.

Photo Credit: CCAI

Workforce

The COVID-19 pandemic exacerbated the problem of finding and retaining skilled workers. Already an area of concern, the workforce challenges in the manufacturing world have reached a fever pitch. Such factors as just-in-time (JIT) manufacturing and succession planning have changed the employment landscape with an increasing number of companies embracing robotics and smart technologies as they plan for the future of their businesses. Through the course of the year, PF reported on how education and outreach programs are working to address workforce concerns and help new talent take advantage of career opportunities.

“Reinvigorating the Workforce”: short.pfonline.com/wrkfrc

DeGeest Corp. showcases Lesta robotic paint technology at FABTECH 2021.

Photo Credit: Products Finishing

Automation, Software, IoT Solutions

Finishing operations have been a slower adopter of IoT and automation solutions, but it seems that we have reached a tipping point where workforce challenges and increasing demand for JIT manufacturing are prompting an increasing number of finishing operations to consider investing in new technologies. Here are a couple of stories:

Podcast: Trends in Automation for Finishers: short.pfonline.com/autotrd

“Let’s Finish Closing the Quoting Gap” by Mark Albert: short.pfonline.com/ppquote

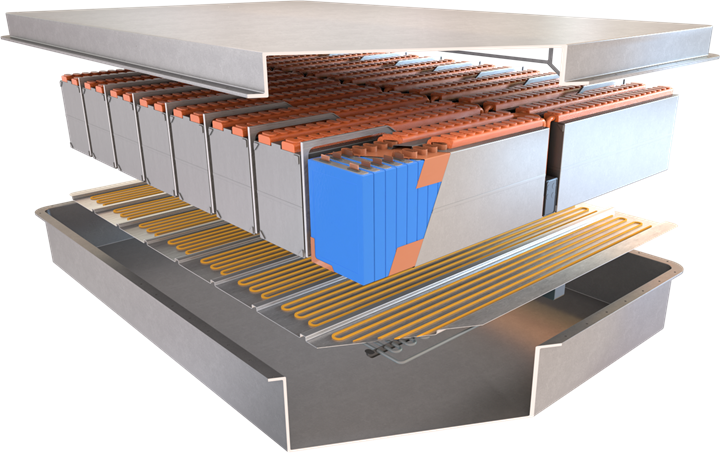

Electric vehicle batteries depend on coatings to help with thermal management, electrical shielding and more.

Photo Credit: PPG

Electric Vehicles

The rise of electric vehicles has been heralded for some time. As global climate change advances, the need to minimize emissions and reduce reliance on fossil fuels has become critical. Electric vehicles are changing the landscape of the automotive industry. What finishing opportunities will arise from the rising popularity of EVs?

“Coatings Drive Electric Vehicles Further” by Jenny Rush: short.pfonline.com/evbat1

Looking ahead

The past two years have been plagued with so many challenges. Yet, as Albert Einstein once said, “In the middle of difficulty lies opportunity.” The finishing industry has so much to gain from working to meet these challenges head on. Automation and IoT solutions can help finishers better handle increasing expectations regarding turn-around times and bridge the communications gap between manufacturers and finishers. At the same time, the changing skill sets needed to man state-of-the-art finishing facilities may help change perceptions about careers in finishing and reinvigorate the workforce. New megatrends such as EVs, autonomous vehicles and urban mobility will continue to yield a need for new coatings that can help mitigate battery overheating and provide antimicrobial protection.

There’s plenty of hard work to be done, but a brand-new day for the finishing industry seems to be on the horizon.

Enjoyed looking back at some of PF’s best stories of 2021? Don’t miss a special retrospective episode of our On the Line podcast featuring some of the most insightful interviews from the past year: short.pfonline.com/OTL13

Related Content

Low-Temperature-Cure Powder Coatings Offer Unique Opportunities

An in-depth look at the advantages of low-temperature-cure powder coatings and the considerations for incorporating them into your process.

Read MoreAdjusting Current and Voltage When Powder Coating

Which manual powder coating gun setting is better to adjust, voltage or current? Jeff Hale of Gema USA discusses when to use different settings on your powder gun to achieve optimal results.

Read MoreSelecting the Right Outdoor-Durable Powder Coating

The powder coating industry offers an array of chemistries to provide an excellent match to the manufacturer’s expectations for outdoor durability.

Read MoreCalculating the Cost of Powder Coating

How can you calculate the cost of powder coating a component if you only know its surface area? Powder coating expert Rodger Talbert has the answer.

Read MoreRead Next

Episode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreMasking Solutions for Medical Applications

According to Custom Fabricating and Supplies, a cleanroom is ideal for converting, die cutting, laminating, slitting, packaging and assembly of medical-grade products.

Read More