These complex parts have been cured in a gas catalytic oven. Source (all photos): Trimac Industrial Systems

Applying heat to a substrate causes a physical reaction which can be different depending on the material at hand. Heat can shrink, soften, harden and dry/dehydrate. So, how does the type of heat technology affect these applications? Not only does the heating process need to be considered, but also the cost and speed of heating to choose the most efficient oven for a process and for the end user.

I spoke with Marty Sawyer, CEO of Trimac Industrial Systems, manufacturer of industrial ovens, to learn about convection, gas catalytic infrared and electric infrared oven technology, as well as some hybrid applications and pros and cons of each type.

Sawyer says that although it is difficult to determine which heat method is ideal for a certain application until she truly understands that customer’s application and what it is trying to achieve, there are some general rules she follows. “If their primary motive is to reduce their cost per piece, I typically try to push them toward catalytic,” she says. “If their primary motive is speed, I typically push them toward electric infrared. If their primary motive is to be able to do anything under the sun, I push them toward convection.”

Each heat technology has benefits and pitfalls that make each type suitable for different substrates, processes, part sizes and shapes, and needs of the end user.

Convection ovens

Convection heat is the most common form of heating technology in thermal processing. Typically involving an open flame burner, air is heated inside of a

This gas-cat cure oven from Trimac is part of a full powder coating system installed in Canada to finish complex tubular weldments.

chamber and then forced over the part with fans and adjustable dampers to create ideal airflow. The burner in these ovens can be gas combustion or electric powered.

“Convection ovens are basically a box of hot air, so it is extraordinarily flexible,” Sawyer explains. “Don’t get me wrong. Some can be very sophisticated as far as how the air is controlled, what you do with the air, and how you turn over the air.”

For instance, Trimac uses individual damper controls inside its convection ovens to properly balance and maintain air temperature throughout the oven chamber. Top, bottom, rear or side-discharge, the airflow within the oven can be directed in a variety of ways based on the part, the necessary temperature and the process being performed.

A batch convection oven is most effective when bringing powder coating in-house, for a custom coating job shop, or a shop that needs small volume heating. With higher volumes of a variety of parts, a conveyorized convection oven can be a good option.

Convection airflow is also useful to balance oven temperature and aid in curing powder on parts with thick and thin areas. This can be done by adding the technology to any gas catalytic infrared oven using Trimac’s ThermalWrap design.

Gas catalytic infrared ovens

Gas catalytic infrared ovens are the most cost effective and energy efficient heating solutions, according to Trimac. These custom-designed ovens, commonly used to cure powder coatings on almost any substrate, can do the same work in a fraction of the space, fraction of the time and use a fraction of the utilities required of a traditional convection oven.

Gas catalytic infrared ovens do not rely on heated, moving air to increase the part temperature. For this reason, they are especially useful for uncured powder or powder coated parts because the technology reduces opportunities for cross-contamination and blowing off powder. However, these ovens are also used for drying, thermal forming, boosting to temperature, and to gel powder coatings as well as for more complex parts.

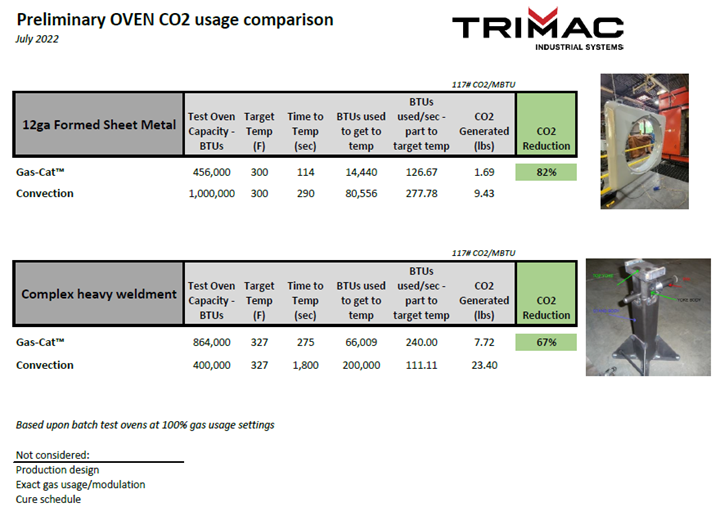

From data compiled in Trimac’s laboratory on its equipment, there was an 82% reduction in CO2 when processing sheet metal in a gas catalytic oven versus the convection oven. Similarly, there was a 67% CO2 reduction when complex, heavy weldment was processed in a gas-cat oven versus a convection oven.

This heat technology catalyzes natural gas, which is more efficient than convection technology. “Gas catalytic is typically 2x but can be 3x faster than convection,” she explains. “This also means its footprint is 2x to 3x smaller.” Not only does this technology reduce the required space necessary to do the job, enabling more space on the shop floor for other processes, but it also reduces carbon usage and emissions.

Sawyer explains that for paint and powder coating applications, convection ovens are often large enough that there is a high level of natural gas being consumed. However, with gas catalytic heat, it is faster, cleaner and cheaper.

Based on Trimac’s testing and data collection, Sawyer believes the savings could be more than 66% CO2 (carbon dioxide) reduction when implementing gas catalytic ovens. “Because you’re only using about a third of the natural gas, you’ll use two thirds less CO2, and you will emit two thirds less CO2, just by changing technologies,” she says.

“Convection is your basic Chevy. Natural gas is a race car, which has more gears and is harder to work with.” – Marty Sawyer, CEO at Trimac.

Not only do operating costs decrease dramatically when less gas is used, but Sawyer adds that gas catalytic can produce a cleaner, higher quality finished part as well.

Although gas catalytic offers many advantages, like any technology, there are some considerations to mention. According to Sawyer, these ovens are more difficult to operate because they require more process control and training than convection ovens.

“I always like car analogies,” she explains. “Convection is your basic Chevy. Gas catalytic is a race car, which has more gears but can be harder to work with. However, with so many gears, you get much more control.”

She adds that because more monitoring and more recipes are required for gas catalytic ovens, operators need to be trained more thoroughly than convection oven operators.

Electric infrared ovens

The greenest, least demanding for fossil fuels, and the fastest heat technology, is electric infrared. The ovens that use this heat method can be designed in various shapes and can be implemented for almost any process involving heat treatment, including annealing, laminating, sintering, curing adhesives, curing powder coatings and thermal forming.

The electric infrared elements can be shaped to match the profile of the part being processed and can be controlled by zones inside the oven. This heating method maximizes the amount of energy absorbed into the part.

Because electric infrared is more powerful than the other types of heat, it is also capable of heating faster than other methods.

If an end user’s objective is to reduce its carbon footprint, electric infrared can be a good solution, depending on the size of the operation.

“If you’re working with a smaller oven, you don’t care as much about the operating costs (of electric),” Sawyer explains. “But if you’re working with an oven more like the size of the building, you might need a substation around it to provide the thousands of amps that you might need to do all the work in electric.”

Because electric infrared is more powerful than the other types of heat, it is also capable of heating faster than other methods. It can sometimes heat 10x as fast as convection ovens, Sawyer says.

Trimac’s Pro-Cat oven combines the speed of electric and the curing ability of catalytic. This oven is especially useful when users are looking to save thousands of square feet of space, heat as fast as possible and reduce the carbon footprint.

But with power comes expense. Therefore, according to Sawyer, in general, electricity is significantly more expensive than gas catalytic, which is the least expensive heat technology.

However, when working with complex parts, electric infrared is limited. As the temperature gets higher with this technology, the wavelength gets shorter and becomes similar to rifle, as the “line of sight” issue becomes a challenge as Sawyer describes it. Because of its process speed, it only heats what is in its path.

Electric infrared ovens are most efficient for boosting large, complex metal parts. Flat parts are also more efficiently heated using this method. For applications using glass, wood, and other substrates, electric is the optimal choice because of speed and the high level of control.

Hybrid options

To combine the benefits of more than one of these heating technologies into one oven, some end users are choosing to integrate electric infrared technology at the front of a convection oven to boost the power of, or “turbocharge,” the convection oven.

However, Trimac is offering an oven model that implements Protherm’s electric infrared elements and Trimac’s gas catalytic methods, called Pro-Cat. “This enables us to shrink the size of the catalytic oven and get the speed of electric infrared without some of the downsides of it, which is its power consumption and inflexibility,” Sawyer explains.

For companies that are heating complex parts, Pro-Cat can be the most successful way to reduce a carbon footprint and reduce process time.

How to choose

Because there is no straightforward formula for deciding which type of oven is best for an application, becoming educated about the different heating methods is a good place to start. When Sawyer is working with customers, she suggests they record the utility cost of a particular oven, the cost to operate it as well as the throughput, work-in-process, and all production costs. With this information, it makes the process easier, but it’s still a matrix, she says.

“My answer to the question ‘what is the best technology?’ is always ‘it depends’,” she says. “It depends on some very basic things like the part’s size and shape that needs to be heated, the process and the substrate. And what are your business needs?”

Working closely with an experienced oven manufacturer and having your parts tested increases the chances of choosing an oven wisely.

Related Content

Oven Door Technology Improves Energy Efficiency

The RollSeal Door brings a compact, energy efficient and safe design to batch and conveyor style thermal processing units.

Read MoreQuick Turnaround is Key for Architectural Coating Shop

This California metal fabricator and coater focuses on fast turnaround and streamlining its processes with 40 years of experience in the construction industry.

Read MorePowder Coating Overcomes Post Forming

Six Sigma methodology, open communication, and collaboration produce results for leading boat manufacturer.

Read MorePowder Coater Leverages Its Manufacturing Mindset for Success

As a former motorcycle manufacturer, this powder coating Top Shop benefits from understanding the finishing industry from a customer’s perspective.

Read MoreRead Next

Specialty Oven’s Hot Benefits and Other Questions Answered

Learn about the advantages of gas catalytic infrared pre-gel ovens in this article, including how they are energy efficient and can save users time and money when integrated into their existing systems.

Read MoreInfrared Ovens Offer Speed with Control for Liquid, Powder Coatings

Curing as much as 75% quicker should make any applicator give infrared ovens consideration.

Read MoreThe EV and the Curing Oven

How will the advent of electric vehicles change paint curing processes and oven requirements?

Read More