Waterborne Conductive Primer, Adhesion Promoter Shows Sustainable Approach

Sustainable primer shows potential for appplication in automobile and wood industries.

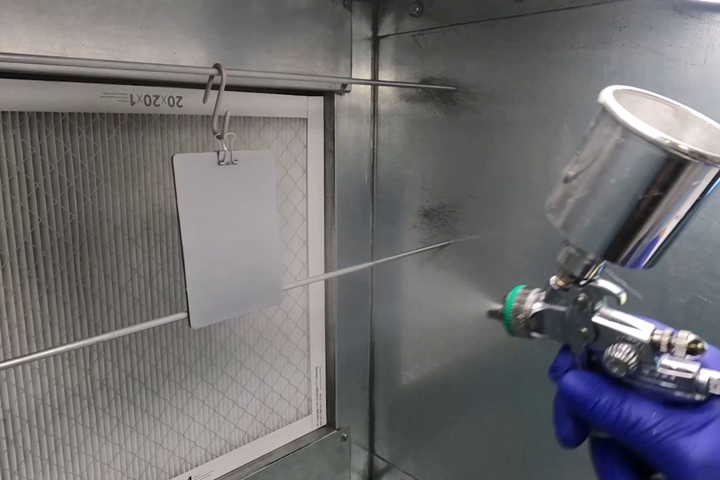

A solution offered by Clear Skies Coatings, a U.S. manufacturer and supplier of paint coatings to the automotive industry, provides a conductive primer and adhesion promoter for themoplastic olefin (TPO) substrate. The solution is a colloidal suspension of powder in water mixed with Tuball Coat_E, a water-based dispersion of graphene nanotubes, available from Oscial.

The low surface electrical resistivity of the TPOs used for automotive fascia, dashboards, cupholders, door coverings and roofing material must be modified with conductive adhesion promoters to improve electrostatic coating efficiency. Usually, carbon black or metal dust are used to enable conductivity in primers. However, they negatively affect the paint’s basic properties and limit the range of available colors.

“Our Ad-Pro Zero formulation is made of a chemistry for powder coat. It is a conductive, sustainable and durable gray-colored coating that combines the benefits of the traditional liquid adhesion promoters and conductive primer with the performance of powder coatings,” says David Detzler, Clear Skies Coatings president. “It enables an easy and clean application on temperature-sensitive materials, such as TPO and wood. The automotive sector is highly sensitive to this combination of benefits. Our new solution is being assessed by Tier-1 in the US.”

Containing less than 0.05% weight of graphene nanotubes, Ad-Pro Zero features a gray color and can be coated with a thickness as low as 0.3 mil, while achieving a surface resistivity less than 105 ohm/sq. Applied on thermoplastic car parts, the product is said to improve the adhesion of the clearcoat, making it possible to reduce its thickness and enable a wide spectrum of color shades.

“This new coating with our graphene nanotubes is a promoter for TPO-based car parts and has high-performance, zero emissions of volatile organic compounds, zero hazardous air pollutants and no halogens. For aftermarket facias, this powder slurry can be used as an ad-pro at about six to eight microns,” says Ian Fellows, Ocsial USA CEO.

According to the companies, the new graphene nanotube solution has potential in the automobile and wood industries as they can benefit from the increased cost efficiency, long-lasting performance and ability to eliminate harmful emissions.

Clear Skies Coatings | (586) 697-5146 | clearskiescoatings.com

Related Content

-

Reduced, Reused and Recycled Powder Coatings Are the Future

They say necessity is the mother of invention, and with millions of pounds of powder coating going into landfills a year, these two companies have found novel approaches to dealing with this waste stream.

-

Powder Coating Overcomes Post Forming

Six Sigma methodology, open communication, and collaboration produce results for leading boat manufacturer.

-

Calculating the Cost of Powder Coating

How can you calculate the cost of powder coating a component if you only know its surface area? Powder coating expert Rodger Talbert has the answer.