Powder Coating

Powder coating is a dry finishing process using sprayers to apply finely ground paint particles to a substrate using electrostatic charge. Powder adheres to the substrate by electrostatic attraction until melted and fused into a uniform coating in a curing oven.

ESSENTIAL READING

VIEW ALLHow to Address Declining Powder Coating Coverage Over Time

Fine particles from reclaim could be to blame for powder coating problems that emerge over time. Avoid problems by keeping hooks clean, maintaining guns and using reclaim powder quickly to avoid accumulation of fines.

Read MoreCuring Oven Basics

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...

Read MoreChoosing the Right Powder Booth Technology

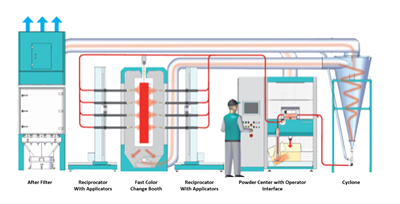

Is your powder coating operation experiencing an increasing number of color change requirements? Nicolas Gervaise of Carlisle Fluid Technologies discusses fast color change single booth configurations for powder coating.

Read MoreConveyors and Paint Systems

Choosing the right conveyor system, coating technology, and ancillary equipment.

Read MoreHow to Build a Powder Coating Brand

Maui Powder Works, a 2022 Products Finishing Top Shop, shares the story behind how it grew from an island job shop to a recognized voice in the finishing community.

Read MoreCalculating the Cost of Powder Coating

How can you calculate the cost of powder coating a component if you only know its surface area? Powder coating expert Rodger Talbert has the answer.

Read MoreLatest Powder Coating News And Updates

How to Address Declining Powder Coating Coverage Over Time

Fine particles from reclaim could be to blame for powder coating problems that emerge over time. Avoid problems by keeping hooks clean, maintaining guns and using reclaim powder quickly to avoid accumulation of fines.

Read MoreTTX’s Automated Conveyor Carrier System Offers Wireless, Flexible Operation

ACC system designed for reliable, consistent point-to-point movement of everything from small to heavy parts.

WatchBlasting vs. Washing

Weighing your surface prep options prior to powder coating? Products Finishing columnist Rodger Talbert discusses the considerations you should keep in mind.

Read MoreExploring Powder Coating for Plastics, Composites and 3D-printed Parts

Advancements in powder coating technology make it a viable surface finish for a growing number of applications using advanced plastics or composites.

Read MoreEpoxy Rebar Company Reinforcing Roads of the Future

Providing epoxy-coated rebar with the ultimate corrosion resistance is Simcote’s focus for the infrastructure industry it serves.

Read MoreInfrared Curing Systems for Enhanced Coating Efficiency

David Weisman LLC introduces its Horizontal Conveyorized Infrared System, designed to efficiently preheat or cure liquid and powder coatings on horizontal products.

Read MoreFeatured Posts

An Altruistic Growth Strategy Puts People First

Professional Plating emphasizes investing in its team and fostering a supportive environment on the shop floor.

WatchPowder Coating Chipping on Aluminum Extrusion

The only way to get reliable results with powder on aluminum that will be used outdoors is to use an aluminum conversion coating that neutralizes the surface so the oxide cannot rapidly reform, according to Rodger Talbert.

Read MoreTop Shop Pivots With Industry Demands

Moving from cars and motorcycles to its current aerospace and architecture customer base, this California powder coatings shop has evolved and grown with the changing market.

Read MoreFactors Affecting Job Shop Profitability

Powder coating expert Rodger Talbert answers a question about procedures that affect profitability, including quoting methods.

Read MorePowder Coating Automation Can Reach ESG Goals for Automotive Parts

By adopting the robotic process automation (RPA) powder applicator, a plant can make significant savings for both the environment and the bottom line.

Read MoreAvoiding Powder Coating Defects on TGIC-Free Metallic

ChemQuest’s Kevin Biller shares how to omit pinholes and voids when powder coating.

Read MoreFAQ: Powder Coating

What is powder coating?

Powder coating is a dry finishing process used to apply a dry coating material. The coating material is made up of finely ground particles of resin and pigment for color, along with other additives for specific functions such as gloss or hardness. The dry powder coating is delivered to a spray gun tip that is fitted with an electrode to provide an electrostatic charge to the powder as it passes through a charged area at the gun tip. The charged powder particles are attracted to a grounded part and are held there by electrostatic attraction until melted and fused into a uniform coating in a curing oven.

https://www.pfonline.com/articles/fundamentals-of-powder-coating

What powder coating is best for my job?

“We must begin by explaining the basic chemistries available in the market today. We’ll cover the basic advantages and key disadvantages that each one of these possesses. Moving forward, some key groupings of exposure must be understood. Examples include accelerated weathering, salt fog and moisture, chemical resistance, flexibility for post-cure bending, durability (both physical and exposure-related) and others.

How to powder coat plastic parts?

The number of plastic parts painted and coated is growing—and in a practically unlimited scope of diversity. In order to avoid painting defects and optimize quality, it pays to carefully scrutinize the entire process. A number of challenges need to be met to this end. These include optimized quality along with strong economic efficiency and sustainability. This is further augmented by ever smaller lot quantities and an increasing variety of colors.

https://www.pfonline.com/articles/coating-plastic-parts-more-efficiently

What coating system gives the best long-term coating performance?

If asked what gives the best protection against corrosion and UV exposure, it would be electrocoat and a super durable powder coating. Whether you have a zirconium pretreatment system or zinc phosphate pretreatment system, either will give very good corrosion performance. The super durable powder coating will give the best weathering performance, meaning color fade and gloss retention in sun-exposed areas.

https://www.pfonline.com/articles/powder-coat-systems-with-the-best-long-term-performance

What is the cost of powder coating?

Calculating the coating cost of a particular part starts with gathering the variables associated with that part. What is the part size, how many of them can you fit into your coating process per hour and how much surface area will be coated?

This process data is used to determine the parts per hour so that the hourly costs can be broken down into a cost per part. The number of pieces per rack, racking centers and line speed can be used to determine the production volume per hour at 100-percent efficiency. This number should be adjusted to compensate for breaks or other factors that reduce the line efficiency.

https://www.pfonline.com/articles/how-to-calculate-the-cost-of-powder-coating

Powder Coating Supplier Categories

- Spray-Mask-Painting Barrier Coatings

- Powder Coating Equipment, Fluidized Bed, Electrostatic

- Powder Coatings, Thermoset

- Powder Coatings

- Spray Booth Sludge Removal Systems

- Powder Coating Sieves, Screening Devices, Sifters

- Spray Booth Coatings

- Spray-Gun Washers

- Powder Coating Equipment, Electrostatic Spray

- Powder Coating Equipment, Fluidized Bed

- Spray Booth Compounds, Water Wash

- Spray-Gun Controls, Memory

- Spray Booths, Paint & Powder Coating

- Powder Coatings, Thermoplastic

- Powder Coating Systems, Engineering & Installation

- Powder Coating Recovery Systems

- Spray Booth Cleaning Materials

- Spray-Gun Movers, Paint or Powder Coating

- Spray Booth Lighting Fixtures

- Tape, Masking for Plating & Painting

- Powder Coating Testing Equipment

.jpg;maxWidth=300;quality=90)