Ecoat has been used in automotive and industrial applications for over 50 years and is one of the key reasons why vehicles no longer rust out like in years’ past. Conventional ecoats have been limited using tin-catalyzed technology and the need for higher cure temperatures (i.e., temperatures greater than 160°C). This leads to ecoat on thinner substrates being overbaked and over-cured more often, resulting in uneven appearance and variations in base color. To address the problem, PPG researchers developed an expanded bake cathodic epoxy electrocoat (ecoat) platform to be deployed across multiple product platforms, including Enviro-Prime Epic 300, to deliver corrosion protection to products with varying substrate types and thicknesses. Through a combination of innovative polymer design and cross linker components, we can now achieve cure at lower temperatures, thereby ensuring well-cured films on thicker gauge substrates at 140°C and reduced chances of overbaking and over-curing on thinner gauge substrates. This breakthrough in cross linker components and resin technology in ecoat systems is truly game-changing.

Why Ecoat?

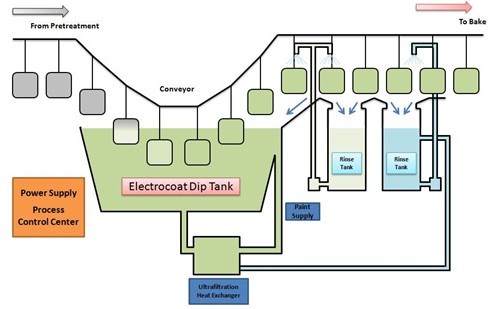

Ecoat is an electrodeposited paint that provides outstanding corrosion protection and adhesion promotion to cars, appliances, airplanes, and any other electrically conductive object that can be immersed in water and baked in a cure oven. These coatings are environmentally friendly in that they are water-based (≥75% water) and generate minimal material waste because they are applied with nearly ≥95% efficiency (no overspray). (Figure 1)

Figure 1: Ecoat process — closed loop creates very little waste.

Photo Credit: All images courtesy of PPG

Additionally, ecoat is excellent for corrosion resistance because it is applied using an electric field such that the corrosion-protective coating seals all exposed metal, even on very complex shapes, until the surface of the metal part is uniformly insulated and protected with paint.

Figure 2: Ecoat covers and seals complex shapes and parts

Like many ecoats, the Enviro-Prime Epic technology platform is epoxy-based. Epoxies form an excellent moisture, oxygen and chemical barrier when cured with a cross linker, making them perfect choices to prevent corrosion at even lower temperatures and with varying steel gages.

Expanded Bake Window

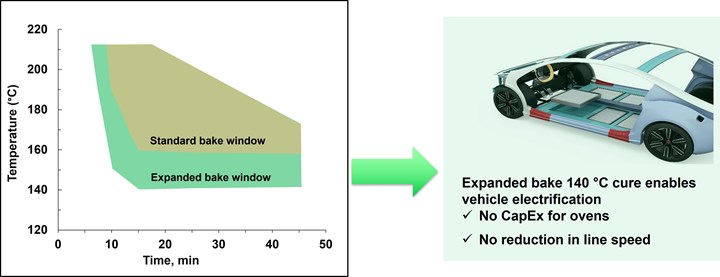

The performance of Enviro-Prime Epic 300 on diverse substrates at varying thicknesses in end-use applications yields superior results with an expanded bake window. An expanded bake window with a low temperature minimum of 140°C was developed for customers looking to bring electric vehicles (EVs) with battery packs to their in-house program. The concept of an expanded bake window is illustrated in Figure 3 below.

Figure 3: Expanded bake window ecoat enables vehicle electrification

Since battery packs of electric vehicles are heavy and require thicker rocker panels to support them, these thick and heavy metal parts do not reach temperatures required to cure standard ecoat. Enviro-Prime Epic 300 provides automotive manufacturers an option for vehicle electrification without the need for oven expansion or reduction in line speed. In addition to these benefits, Enviro-Prime Epic 300 provides superior corrosion performance, adhesion promotion, and improved appearance within this expanded bake window.

Expanded Cure Performance

As the automotive industry shifts to electrification, utilization of varying substrates and varying thicknesses to meet weight-based structural requirements, there is a push to simplify manufacturing and keep all electrocoating aspects on the same production line to increase the speed of manufacturing. This brings a new challenge of increased oven temperatures and increased time needed to cure conventional ecoats on heavier gauge substrates. When this thicker metal is processed within a standard automotive body, this leads to the thinner body surfaces heating up much faster and becoming over cured. This over cure causes concerns with appearance, corrosion and adhesion performance which could bring about increased warranty claims.

Expanding the ecoat bake window with solutions such as Enviro-Prime Epic 300 alleviates this concern and enables a simpler solution for the manufacturer. It also eliminates the costly exercise of processing these parts on separate lines and assembling later, which allows for reduced risk and handling of materials by simplifying the production process.

Energy Savings/Increased Throughput

An expanded ecoat bake window creates new opportunities for manufacturers. If a constant gauge of substrate is used, operators now have the option to either decrease oven temperatures from the current set points or to increase the speed with which coated parts can travel through the oven. The first scenario has several great benefits, primarily those of reducing energy costs and reducing carbon emissions in gas-fired ovens by setting lower temperature points, all without sacrificing performance characteristics. The life cycle analysis for expanded bake ecoat processing has shown in some situations that lowering oven temperature can reduce CO2 emissions by 10%. In the second scenario, the manufacturer could maintain current oven temperatures, but increase the speed at which parts move through the oven. This would in turn allow for increased production throughput.

Removal of Tin Catalyst

Due to increasing regulatory requirements, tin-catalyzed products have become unfavorable in many regions. Using PPG’s novel cross linker components, Enviro-Prime Epic technology utilizes a tin-free approach to catalysis yet provides equivalent or better performance than standard tin-catalyzed ecoat while meeting global regulatory requirements.

Impacting the Future of Automotive and Industrial Parts

The ability to meet demanding performance requirements across an expanded bake window provides real and critical benefits to both automotive OEM and industrial parts. By employing these expanded cure temperature ecoat solutions, facilities can not only process varying gages of substrates simultaneously, but also provide manufacturers with a more sustainable solution for maintaining or improving throughput.

About the Author

Related Content

Masking Solutions Provider CFS Dramatically Expands Capabilities and Capacity

Custom Fabrication & Supplies (CFS) completed a new plant expansion packing 10 times the capacity into twice the space. It dramatically enhances the supplier’s custom capabilities to provide extremely precise and cost-effective masking solutions.

Read MoreFinishing Systems Provider Celebrates 150 Years, Looks to Future

From humble beginnings as an Indiana-based tin shop, Koch Finishing Systems has evolved into one of the most trusted finishing equipment providers in the industry.

Read MoreBASF Advancing E-Coat Applications

Although their e-coatings have been deployed millions of times, BASF Coatings is still learning more.

Read MoreCoating Systems with the Best Long-Term Performance

The best protection against corrosion and UV exposure, says Axalta’s Mike Withers, is electrocoat and a super durable powder coating.

Read MoreRead Next

The 2024 Ford Mustang: All the Colors Available

Although Chevrolet has announced the end of the Camaro and Dodge is offering “Last Call” editions of the Charger and Challenger, the Ford Mustang is launching to its seventh generation.

Read MorePowder Coating 4.0: Smarter, Faster, More Efficient and Connected

New tools reduce cost and waste, lower manufacturing footprint of powder coating operations.

Read MoreEpisode 42: An Interview with Robin Deal, Hubbard-Hall

Hubbard-Hall wastewater treatment specialist Robin Deal discusses the latest trends in wastewater management.

Read More