Before Sowmya Laxminarayanan went to work for the most innovative company in the world, she first had to endure a similar taskmaster: her father.

Once, when she as in the 10th grade and living in Sri Lanka where her father was sent to work, he announced in November that the family was moving back to India, putting in peril the critical school exams she was slated to take in May that would have a major impact on her education and career.

“My dad looked at me and said, ‘Take the exam in January and be done with it,’” Laxminarayanan recalls. “When I told him I would be taking the exam five months before the material was even taught, he said ‘Just give it a shot. You won’t fail. And if you do, you can retake it.’ He believed in me.”

That life lesson prepared Laxminarayanan for what lie ahead, which included coming to the U.S. by herself to take graduate classes at the Massachusetts Institute of Technology, and eventually getting her first job at Apple. Today, she is a senior subject matter expert (SME) for Surface Finishing and one of Products Finishing’s 40-Under-40 honorees, which recognizes the top young talent in the surface finishing industry.

Over her 11-year career for one of the top technology companies in the world, Laxminarayanan has been deeply involved in both quality and process engineering roles across multiple product platforms in the consumer electronics space. Her direct contributions in surface finishing have led to delivering aluminum enclosures in an array of exacting colors and superior corrosion resistance.

Those who work alongside Laxminarayanan say her own genius is her fearless attitude when dealing with new technology or technical challenges, her hands-on ability, as well as cutting through ambiguity and collaborating seamlessly with a large cross-functional team to drive what really matters.

“No one understands better than Sowmya how the various engineering and business groups contribute and operate together to produce a final product,” says Judy Runge, Ph.D., president of CompCote International and one of the foremost experts on aluminum anodizing, who now works alongside Laxminarayanan.

Runge says Laxminarayanan is driven to innovate by bringing the newest anodizing processes to production and, together with her team, make the beautiful appearance and performance of the anodic oxide finish which so defines her company’s products.

“Her leadership and knowledge of the anodizing process make her the only woman who makes iPhones beautiful in mass production,” Runge says.

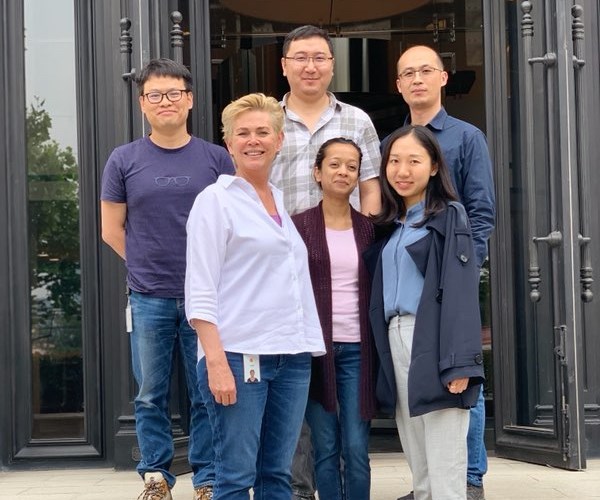

Laxminarayanan says she and Runge are nicknamed the “Dynamic Duo” at the company headquarters. She credits Runge as her mentor and someone she can bounce engineering ideas off of, as well as Christoph Werner, Ph.D., her senior manager for surface finishing and Wesley Xue, her global team-mate and manager of the Asia-Pacific finishing team.

“Surface finishing has really evolved over time,” Laxminarayanan says. “ In our company, the design teams constantly raise the bar with every new product. The confluence of aesthetics and performance drive our teams to delve deep into the science of finishing and find solutions that exceed the bar and are scalable. You can now take your wearable device and go swimming. The anodic oxide has to be more durable and reliable than ever before because of the environmental performance demands by our customers.”

Laxminarayanan originally started her career as a quality engineer before transitioning to surface finishing. Now a mother to a 4-year-old daughter, she says she is married to an “equally accomplished husband.” The challenge has been balancing the constant global travel in her career with the happiness of being with her family and friends.

“Because I travel so much, when the new phones came out, I took my daughter to the store and showed her all the colors and said, ‘this is what mommy was doing all that time I was away,’” she says. “I never started out thinking I was going to be doing this. I didn’t go after finishing, but finishing found me. It was the path I was destined to be on, and I just absolutely love it.”

Related Content

Chicago-Based Anodizer Doubles Capacity, Enhancing Technology

Chicago Anodizing Company recently completed a major renovation, increasing its capacity for hardcoat anodizing and Type II anodizing.

Read MoreBryan Leiker, MFACA, Discusses CARB Public Hearing Over Calif. Hex Chrome Ban

Bryan Leiker, executive director, Metal Finishing Association of California, offers a recap of a January 27, 2023, public hearing conducted by the California Air Resources Board prior to an impending ruling on a proposed ban of hexavalent chromium use for finishing operations in the state.

Read MoreAnodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreMasking Solutions for Medical Applications

According to Custom Fabricating and Supplies, a cleanroom is ideal for converting, die cutting, laminating, slitting, packaging and assembly of medical-grade products.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More

.jpg;maxWidth=300;quality=90)