Dear Advice & Counsel,

I am the new foreman at an airline plating shop and my experience in metal finishing is minimal. I was wondering if you could provide me with a quick primer on the kinds of metals used in the airline aerospace industry.

Signed, New Guy

Dear New Guy,

This month's metal is Aluminum.

The basic physical/chemical properties of this metal are:

|

Symbol:

|

Al

|

|

Atomic number:

|

13

|

|

Valence:

|

+3

|

|

Crystal structure:

|

CCP (Cubic-close packed)

|

|

Density:

|

2.7 g/cm3

|

|

Melting point:

|

660ºC (1220ºF)

|

|

Soluble in:

|

Most acids, soluble in alkali

|

|

Insoluble in:

|

Nitric acid, acetic acid

|

|

Color:

|

Silvery white

|

|

Discovered:

|

1825

|

|

Commercialized:

|

1885-86

|

|

Unusual property:

|

Powder is flammable

|

|

Magnetic:

|

Not magnetic

|

|

Corrosion resistance:

|

Low except for pure metal

|

|

Joining methods:

|

Welding, Brazing, Adhesives

|

While the existence of aluminum as the compound Al2O3 (alumina) was well known early in the eighteenth century, it was not until 1825 that Oersted first isolated impure aluminum powder by reduction of aluminum chloride with sodium amalgam. By 1850, Henri Sainte-Claire Deville was producing aluminum via reduction with sodium, but at an uneconomical cost (the price of the produced aluminum would have been the same as gold).

In 1885, the Crowle brothers produced aluminum alloys containing iron and copper, and in 1886, after the invention of the dynamo, the electrolytic production of aluminum made it economical enough to be a viable commercial metal.

While pure aluminum is very soft and ductile, aluminum alloys have exceptional strength for the weight, making it ideal in weight-critical applications such as aerospace and automobile components.

Aluminum can be heat treated to obtain surface hardness combined with core ductility for use in fatigue-wear applications. Pure aluminum has excellent corrosion resistance, in the absence of corrosive chemicals, as it quickly forms a clear oxide film immediately upon exposure to air. It is one of the few metals that are not chemically attacked by nitric acid. Once aluminum is alloyed with more noble metals such as copper and zinc, it loses some of its corrosion resistance and requires treatment for adequate service life. Copper has the most pronounced effect on the corrosion resistance of aluminum, while silicon and iron have a moderate effect.

After silver and copper, aluminum has the next highest electrical conductivity of all commercially available metals. Aluminum is so low in magnetism that it can be used in EMI shielding applications. Aluminum can readily be separated from steel using magnets or devices that depend upon difference in density.

Aluminum can readily be recycled by melting scrap. While there may be some yet to be fully proven links to adverse health effects by exposure to aluminum, it is considered a non-toxic metal, suitable for use with food contact applications and its corrosion products generally are low in toxicity.

Aluminum is an amphoteric metal that is readily attacked by common acids (nitric and acetic being exceptions) and by alkaline solutions.

Aluminum is a highly active metal that will convert to aluminum oxide almost instantaneously, if clean aluminum is brought into contact with oxygen (from the air for example). Some processes take advantage of this tendency and actually produce a thin oxide film over cleaned aluminum by chemical action (sometimes called controlled oxidation).

The third method of inhibiting the movement of dislocations involves deforming the crystal structure of the aluminum by physical means such as pressure rolling, so that there is no clear path for the movement of dislocations and so that they tend to be so numerous that they pile up into each other creating barriers to the movement of others.

Aluminum alloys

Pure aluminum is very soft and ductile because of the presence of numerous dislocations in its crystal structure. Movement of these dislocations along slip planes prevents pure aluminum from carrying any significant load without deformation.

There are three main methods used to strengthen aluminum. By adding alloying elements, “foreign” atoms take up the vacancies producing the slip planes and act as barriers to the movement of dislocations. Similarly, by dispersing microscopic particles (examples Mg2Si and CuAl2) of alloying elements, through heat treatment methods additional/different barriers to dislocation movement can be created. When this heat treatment is not well controlled, there can be too much localized variation in composition which can lead to problems in cleaning, etching, and anodizing. For example, Mg2Si does not etch as readily as bulk aluminum. If it is not finely dispersed, localized pitting can result. Buffing/polishing problems and appearance issues after cleaning and etching are the most common issues resulting from poor thermal treatment processing.

Silicon is a major alloying element in all casting alloys and in 4000 and 6000 series wrought alloys. The role of silicon, as well as most all other alloying elements is to add strength, fatigue resistance and/or toughness to the metal. In castings, silicon acts to allow aluminum to flow better into thin cavities and crevices of molds. For this reason, some castings may have more than 12% silicon.

Unless dispersed in the alloy as fine inclusions of Mg2Si, large silicon-based inclusions yield buffing problems, as illustrated in Fig. 1. Silicon is very hard and when the aluminum is buffed, the softer aluminum is abraded away from the inclusion, leaving a protruding hard particle in the surface. Subsequent cleaning and etching operations will tend to undercut this inclusion, removing it and leaving a pit behind.

Silicon and silicon-bearing compounds tend to be insoluble in most any chemical solution, except acids containing fluorides. If not removed by etching, the silicon alloys in the surface may result in the coloration (tan shades) of the anodic film.

Iron is typically an impurity in the alloy and it has the most dramatic impact on anodizing aluminum, as even very small percentages tend to reduce brightness and at higher levels can cause dark gray coatings.

Manganese can affect the color of the anodic film at concentrations as low as 0.3%, yielding brown tones when heavy thicknesses are produced.

Magnesium tends to produce clear oxides under anodizing conditions. High concentrations can yield reduced clarity.

Copper does not impact the color of the anodic film unless it is present at concentrations over 2%. At levels above 2%, the hardness and clarity may be impacted.

Zinc may be present at up to 5% without impact on the color of the anodic coating, unless the zinc is present as discrete particles, in which case it may produce brown, streaky coatings.

Titanium is added to aluminum alloys as a grain refiner. The impact of titanium on the anodic film is similar to that of iron.

Chromium at levels over 0.3% can add yellowish tones to the coating. Its presence lowers electrical conductivity dramatically, making anodizing (without burning) difficult). Chromium may be found in trace amounts in many alloys of the aluminum-magnesium, aluminum-magnesium-silicon and aluminum-magnesium-zinc groups. If present in amounts above 0.35%, chromium can yield very large inclusions especially in alloys containing manganese, iron and titanium.

When finely dispersed in wrought products, chromium can inhibit nucleation and grain growth in aluminum-magnesium alloys. Chromium can also prevent recrystallization in aluminum-magnesium-silicon or aluminum-magnesium-zinc alloys during hot working or heat treatment.

Making aluminum parts

At aluminum production facilities the aluminum alloy is “chill cast” into ingots (direct casting of the molten alloy is also possible). The molten aluminum is poured into molds and water is sprayed onto the molded aluminum in an attempt to solidify it as rapidly as possible (to produce the smallest grains). Because the outside cools faster than the inside, and because alloying elements have different solidifying temperatures than aluminum, the composition of the ingot is not homogeneous throughout a cross section of the ingot.

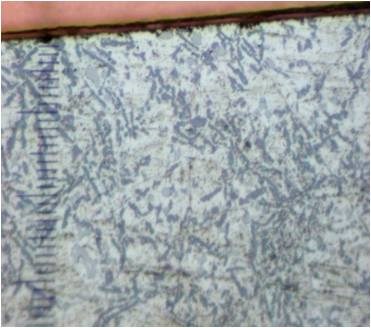

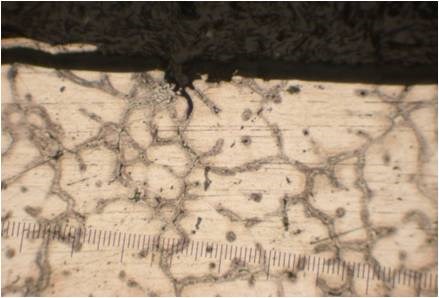

The next step is to homogenize the ingot by heating it up to a temperature where the alloying elements can be redistributed by a diffusion process. This temperature is high enough to accomplish the goal without re-melting the aluminum. If this operation is conducted under the best of control, an ingot will display a uniform distribution of alloying elements, shown in the cross-section of Figure 2 (100×. A non-uniform distribution of the alloying elements results from poor homogenization of an ingot, as in Fig. 3 (100×).

The ingots must be converted to basic shapes. This is performed by either extruding the aluminum, rolling it into sheets, casting or forging, followed by final machining and surface finishing operations.

More on aluminum next month

Contact Frank Altmayer at:

Scientific Control Laboratories, Inc.

3158 Kolin Ave.

Chicago, IL 60623-4889

E-mail: faltmayer@sclweb.com

.jpg;maxWidth=300;quality=90)