Coloring the Cosmetics Industry

Anodizing aluminum parts for color-critical customers.

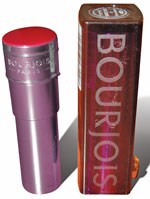

If ever there was an industry that was all about image, it's cosmetics.

If ever there was an industry that was all about image, it's cosmetics. Makers of fragrances and other cosmetics spend millions to find the perfect spokesperson, design an appealing package and create just the right promotional pitches to a carefully researched target audience. An undeniably key component of a cosmetic's packaging and overall image is color, which can spell the difference between billions in sales and an also-ran product destined for the clearance shelf of history. Indeed, color is key, but mass producing millions of color-perfect product parts time after time is no easy task.

For many leading manufacturers of cosmetics and health and beauty products like Revlon, Estée Lauder, Mary Kay, Ralph Lauren and Gillette, the color reproduction solution is found at Anomatic Corp. (Newark, OH). The company reports that it is North America's largest supplier of anodized components and the world's largest producer of small anodized metal pieces.

The eight lines at Anomatic's 150,000 ft2 headquarters facility in Newark (it also has two lines at a facility in China) annually churn out nearly a billion anodized aluminum components primarily for the cosmetics and personal care industries. Every component tells a story of precise color matching that's based on a color standard board kept under lock and key.

THE ART & SCIENCE OF COLOR MATCHING

"The vast majority of what we do is color matching, and this industry (personal care) is very touch and sight oriented as far as color," says Mark A. Ormiston, director, research and development, for Anomatic Corp. "It's much like the fashion industry in that they like the way a certain color looks in the whole packaging scheme. We sometimes get a color chip or maybe a piece from a package, but often it's just a concept. Obscure items like bird feathers, cloth swatches or a piece of antique metal have been used to formulate color matches."

Ormiston explains that color matching typically is a hands-on process involving back and forth color sampling with customers over several days.

"We will do some preliminary matches with our arsenal of dyestuffs and start producing sample pieces. It's fairly fast track, and then we'll arrive at what we call a range board which typically shows variation in color saturation (depth) with the same hue (tint)," says Ormiston, adding that Anomatic produces 300-400 custom colors each year for clients. Once the client signs off on the range board, a matching operational standard board is produced and the original range board stays locked in a dark cabinet to avoid damage.

"For some of the more popular historic cosmetics, we have matched the same color for 10 years and have run millions upon millions of a variety of different components," says Ormiston. "That can be very difficult at times because anodizing is a conversion coating process of aluminum, and the pedigree of the aluminum is incredibly important. So, we have to carefully watch over the physical aspects of the aluminum alloy because anything that's in the aluminum chemistry can alter the finish of the product."

Ormiston adds that Anomatic also is asked at times to match the colors and finishes of different metals like nickel plated brass or chrome steel. "We've been pretty successful at that. A lot of it is tight process control and constantly watching the standards and frankly, part of it is our experience. We can match any color, including deep black except pure white. That's the Holy Grail of anodizing," he says.

FOLLOW THE LEADER

Anomatic was founded in 1965 by William C. Rusch, who pioneered the concept of a high speed, high volume automated assembly line machine for anodizing small aluminum parts. Rusch patented his Anomatic continuous titanium belt conveyor system in 1967, and its automated technology remains the heart of the company's anodizing lines today. Rusch retired in 2002, but seven family members remain active in Anomatic today, including William B. Rusch (president) and Scott Rusch (CFO and executive vice president). Today, Anomatic is a diversified manufacturer to many industries including personal care, automotive, spirits, sporting goods, appliances, pharmaceutical and aerospace.

According to Ormiston and Anomatic Marketing Manager Steven Rusch (founder William C. Rusch's grandson), their continuous motion anodizing line that moves parts up and down through the various preparatory and process baths offers many advantages as well as some unique challenges.

"The key competitive advantage to the system my grandfather designed is the consistent quality and color achieved by virtue of the 'follow the leader' system," says Rusch. "The titanium belt is electrically conductive, resistant to corrosive acids used in the bath and strong, which is important since the belt is 700 feet long. So, doing 'follow the leader' with the serpentine system, you're getting a uniform finish inside and outside the part."

"We perform Type II anodizing with sulfuric acid and water where we electrically charge the titanium belt and the tooling positively," says Ormiston. "The sulfuric acid splits the water up and makes its oxygen available, so the positive aluminum article collects oxygen atoms and becomes aluminum oxide that slowly grows, getting deeper and deeper," he says.

"The advantage of the motion in our system is you get complete, consistent coverage of the part," continues Ormiston. "Altering the anode cathode geometry allows sharp edges to get the same coverage as large flat surfaces. If you are performing stationary anodizing where you have the same relationship all the time, you may experience thicker coatings on sharp edges versus flat surfaces and that is a big issue in color because you can get deeper color on the sharp edges and end up with two-tone parts.

"Also when you drop the flight bar into the dye cell in stationary anodizing, the bottom piece is actually in the solution longer than the top piece so you get some stratification there with darker pieces on the bottom and lighter on the top. The serpentine design of the Anomatic system processes each component the exact same dwell time," says Ormiston, adding that the system also eliminates the potential problem of gas pocketing in polishing cells.

Despite the inherent advantages the Anomatic system provides, Ormiston acknowledges that it also poses challenges in precise color matching.

"With the conveyorized tank arrangement, we do not have the independence of dwell time in the individual tanks that a lot of other people have, where if I wanted it darker in the anodizing cell I'll just give it an extra minute," he says.

"You can't do that so we have to alter the other parameters like temperature and speed; things that other people may not ever have to do. Also, the smaller, energy efficient tanks can be very dynamic. It's very process control oriented, and we have a lot of equipment to control these tanks and monitor everything carefully."

A ONE-STOP SHOP

Rusch contends that becoming a one-stop, vertically integrated operation has been a key to Anomatic's success in the demanding cosmetics industry. "Anodizing has always been our core technology, but recently we've integrated into metal stamping, decorating and assembly," he says, adding that the company now operates 51 stamping presses worldwide. "That means we're a one-stop solution for our customers."

"About 60% of the parts we anodize now have been fabricated in house," adds Ormiston. "Once we have been given a print or a concept from a client, we form the part on our stamping presses, clean them, anodize them and then a lot of times, we assemble a plastic piece to them and ship a fully finished piece to the customer."

Ormiston says the high speed, high volume service Anomatic offers, to what is in many respects a custom-order industry, is a sizable advantage. "If all the parts were round, it would be kind of easy because you could build some fairly adaptable automation systems and you could run the same widgets all the time," he says. "Speed to market is paramount in the personal care industry, so you need to be quick on your feet. If they have a Super Bowl commercial already paid for and the store shelves are ready for it, but they miss the launch date because the supplier isn't ready, that's a huge problem for everyone."

Read Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read More

.jpg;maxWidth=300;quality=90)