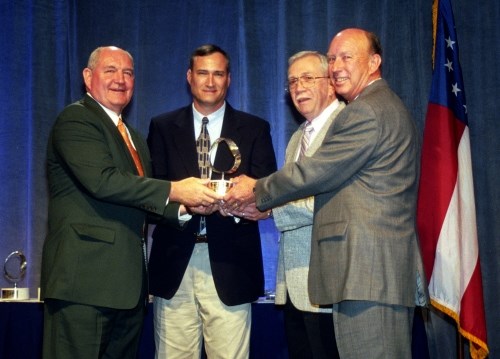

A Conversation with … Jim Jones, Dixie Industrial Finishing

Longtime plating veteran and industry advocate Jim Jones has worked for Dixie Industrial Finishing in Tucker, Georgia, for more than 54 years.

Longtime plating veteran and industry advocate Jim Jones has worked for Dixie Industrial Finishing (DIFCO) in Tucker, Georgia, for more than 54 years, following in his father’s footsteps. He is retiring from his position of vice president to spend time with his wife, Carol, his grandkids and his hobbies, which include flying. We caught up Jim just before he took flight in his 1946 Globe Swift; you can read a longer and more insightful version of his answers online at pfonline.com.

Q: What led to your decision to retire?

A: At age 72, I am still passionate about the business and industry I could continue to be engaged consulting and being a mentor for the younger generation at DIFCO. My wife Carol and I would have more time to spend traveling, visiting children, grandchildren and friends. There are still a lot of places in this country we would like to visit.

Q: Will you still be involved in Dixie Industrial Finishing, and in what capacity?

A: I am still passionate about DIFCO and the metal finishing industry and will continue to be engaged as a consult on special projects, continue certain long term relationships with customers, vendors and others in the metal finishing industry, be involved in NASF, government affairs, advocacy and being a mentor for the younger generation at DIFCO.

Q: How did you get your start in the finishing industry?

A: I grew up in the business. My father got his start in the plating industry during WWII where he worked for Air Service Command, in the plating shop at Warner Robins Air Base just south of Macon, Georgia. In 1943 he enlisted in the United States Marine Corp, serving in the south pacific. After WWII he was employed by Simmons Plating Works in Atlanta, 1946-1959. In 1960 he was one of the three founders of DIFCO. My first summer job in 1958 was at Simmons Plating Works. During that summer I worked on the black oxide processing line, hot dip tin line and bright dipping of brass line. In the summer of 1959 I was again at Simmons Plating Works. During this period I was assigned to the copper, nickel, chrome line and silver plating line. DIFCO started production in March of 1960. I graduated from high school that year and stared at DIFCO June 1960. That first year, I swept floors, worked in the polishing department, on the zinc plating and nickel chrome line, hard chrome line, did analysis for process control and truck driving, picking up and delivering customers product and calling on customers and selling the benefits of doing business with DIFCO. After about a year of working and attending Georgia State University, I decided to join the United States Air Force. I knew I wanted to serve in the military, as it was a family tradition. I had three uncles in the USAF which influenced my decision for the USAF rather than the USMC. I served in the Minuteman Missile Program at Vandenberg AFB, CA and attended Alan Hancock College. I also had for a while a part time job in a plating shop in Santa Maria, CA. Several months before my enlistment was up my father asked me what my intentions were. I told him I had given thought to making the USAF a career; my mother’s second husband asked if I was interested in working for him in the jewelry industry in California. Then my dad said “I need you”, the decision was made. In 1965 I was granted an early discharge from the USAF to start spring quarter at Georgia State University. I also started back at DIFCO at the same time. My dad died in 1972 and Dick Russell, one of my father’s partners, became one of my most important and trusted mentors. Looking back perhaps Dick became one of the other fathers in my life. We had a great relationship until he passed away 8 years ago. His family is very special to me. Another especially important person for the success of DIFCO is John Cone who retired about eight years ago yet continues to be engaged on special projects as a consultant. Dick’s son-in-law David Henderson now has the leadership of DIFCO and he too is and has been another important person in my life. Coming behind David is his nephew Chris Henderson. Proverbs 27:17, Iron sharpens iron as one man sharpens another. DIFCO is can contribute its success to the relationships of all that made it happen, Because ” Iron Sharpens Iron As One Man Sharpens Another”. All of us are better than one of us.

Q: After 50 years, where do you now see the finishing industry headed?

A: The industry has changed from operating a plating shop from the seat of your pants, with no EPA/OSHA regulations and little knowledge about actual cost per unit produced. I now see the successful businesses having a commitment to go beyond compliance on EPA/OSHA requirements, using sophisticated programs and management tools to provide true and total cost for each unit produced on each process line and building a talented and strong team of managers having responsibility for their departments. These teams of managers need to meet on a regular basis to demonstrate that “all of us are smarter than one of us”. I feel there will be fewer small “Mom & Pop Shops” , but larger shops with greater depth in abilities, diversified capabilities, accreditations and production capacities to meet the demands of OEM’s and their supply base. I feel all of those engaged in the metal finishing should be a member of NASF and participate to level that time and resources allow. They should be a voice for not only their business but also for the metal finishing industry. I would also encourage each person in the industry to be engaged in the local and state level on letting them know how their business is affected by policy on the local, state and national level. We need to promote not only our business but our industry, if we help protect our industry we will better protect our business and our customer base.

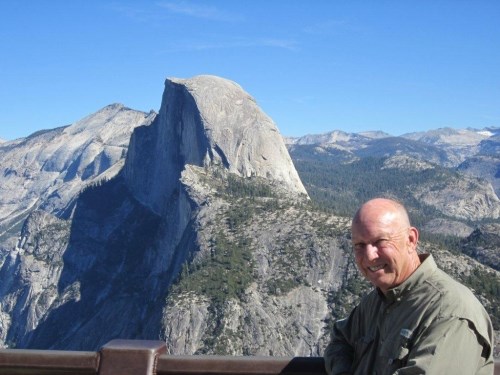

Q: You say you’ll look to refurbish another plane in retirement. Tell us about your flying hobby and how much you get airborne?

A: I still have the airplane I learned to fly in, a 1946 Globe Swift. Over the forty year period the plane has gone through many upgrades in avionics, engine and other approved modifications to improve the performance and safety. I have owned it for over 40 years. I have approximately 5,500 hours flying time and am now averaging about 100 hours per year. I have flown the Swift to the four corners of the U.S. I have flown it to California about 15 times and to Alaska. I have landed in all but about five states. Twenty five years ago a good friend who has a Swift and I purchased another Swift for spare parts and possibly doing a restoration. I had said it would be a retirement project. This is one I will be doing the restoration on. It will not have all of the performance enhancements of the other Swift will have safety improvements and look much like it did when it rolled out of the factory in Fort Worth, Texas in 1946.

Q: What’s the best piece of advice you were given, either personally or professionally, and who gave it to you?

A: Here's a few:

• Your word is your bond. You look a person in the eye, shake hands, and make a commitment you are bound by your word (my father).

• Any job worth doing is worth doing right the first time (my father).

• Never give up (my father).

• Have patience, be persistent, have perseverance and use prayer (my grandfather).

• There are two rules to formation flying; rule No. 1 is never be out of position, rule No. 2 is refer to rule number one (a Navy friend).

• Consistency with a purpose is the key to success (Chinese fortune cookie).

Q: What did you want to be when you grew up?

A: You are going to grow old, but you do not have to grow up. If and when I grow up I want to be in the plating/metal finishing business. It is challenging, interesting, demanding, rewarding, fulfilling and you meet some wonderful and talented people. Every day is different with many different problems to solve, it is not boring. I had three uncles who made a career of the USAF. I was very close to them and thought I might one day make the USAF a career. This was when I was about 12 -14 years old.

Q: What was your first job, and what did you learn from it?

A: Paper route, your responsibility is getting that newspaper delivered everyday on time, rain or cold. Customers wanted their paper on time, but did not always pay on time.

Q: If you had $100,000 to give to a charity, which one would it be?

A: My church, Boys & Girls Club, Ferst Foundation for Early Childhood Literacy, Wounded Warriors, Salvation Army and Humane Society.

Q: What was your first car, and what is your dream car?

A: 1940 Ford Coupe. My dream car was a Red 1959 MG/A. The dream came true, but in the form of a Red 2006 Honda S2000.

Q: What leadership traits have helped you along the way?

A: Practice what you preach. Don’t ask anyone to do anything you wouldn’t do or haven’t done. Empower people to make mistakes; if they do not make mistakes they are not making decisions. You can let people know what the job or mission is but you do not need tell them how to do it. Let them know you are available to assist if needed. Follow-up but don’t foul up by micromanaging.

Q: If you could trade jobs with anyone for a day, who would it be?

A: Someone who could change or encourage changes in regulations and trade policy that would reverse the exodus of manufacturing jobs in the U.S. allowing more manufacturing of product and bringing greater opportunities for the metal finishing industry. Most of those in the metal finishing industry don’t make anything, they just make their customers parts look better, work better or last longer. The metal finishing is dependent on a strong domestic manufacturing base.

Q: Where would we find you on a typical Saturday?

A: Early morning coffee and breakfast with my wife Carol, at the airport doing routine maintenance on one of the airplanes, flying doing light aerobatics, flying formation with special friends, biking, working in the yard, dinner with Carol and possibly friends.

Related Content

Zinc Phosphate: Questions and Answers

Our experts share specific questions about zinc phosphate and pretreatment

Read MoreNASF/AESF Foundation Research Project #122: Electrochemical Approaches to Treatment of PFAS in Plating Wastewater - 7th Quarterly Report

The NASF-AESF Foundation Research Board has selected a project on addressing the problem of PFAS and related chemicals in plating wastewater streams, studying PFAS destruction via electrooxidation and electrocoagulation. Our last report described the results from experiments of EO with a Magnéli phase Ti4O7 anode on the degradation of eight perfluoroalkyl acids (PFAAs). In this seven quarter report, we describe work to further explore how the degradation of different PFAAs are related to their molecular structures.

Read MoreHubbard-Hall Acquires BioConversion Technology

The acquisition adds experience and biologics to the AquaPure product line.

Read MoreDefoamer Designed for Waterborne Coating, Printing Ink Formulations

Evonik’s Tego Foamex 812 exemplifies the company’s sustainability strategy for the paintings, coatings and inks industry.

Read MoreRead Next

A ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read More

.jpg;width=860)

.jpg;maxWidth=300;quality=90)