Autonomous Heating System Features Built-In Safety Measures

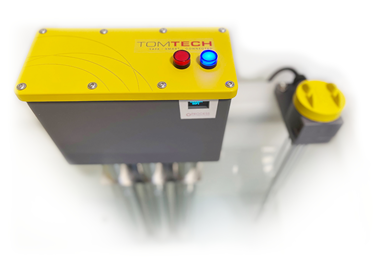

Process Technology’s Tomtech heating system features remote monitoring, built-in safety features and autonomous operation.

Process Technology (Willoughby, Ohio) is launching its new Tomtech heating system that operates autonomously without external controls. According to the company, proprietary Industrial Internet of Things (IIoT) technology makes Tomtech a feature-rich, easy-to-use solution for companies that want to increase uptime, improve quality and lower the total cost of ownership with assured safety. Phil Bearden, director of new product development, says the design goal of Tomtech is “to add as much forethought and to drive three things: safety, autonomous operation and human connectivity.

The Tomtech system comes with built-in safety features that enable the heater to recognize adverse conditions, immediately notify operators and adjust fluid levels or automatically shut down. The Tomtech system runs itself and lets operators know the status. “We’ve designed multiple layers of safety to ensure heaters won’t operate if any safety system fails or is bypassed,” Bearden adds. Red and blue LED lights are also present on the heaters to give operators a visual indicator of when a heater is in need of maintenance.

In addition to the safety features, users can remotely monitor the conditions of the heater on their smart device via automatically generated webpages, meaning there is no need to download a separate app or software. The webpages display live data on tank temperature, cycle counters, schedules that operators can program, data logs, maintenance reminders and more.

Process Technology has also designed proprietary mesh networking capabilities that enable multiple heaters to operate together in one vat. Bearden says, “We geared it to go in a lot of different sized shops. This is very scalable for all operational sizes.”

Additional product specifications include an operating temperature of up to 300°C, storage temperatures of -40 to 85°C, relative humidity of 0 to 100%, wattage of 3000 to 36000 W and voltage of 240 to 480 V. The heater is FCC Part 15B and UL 499 certified, and it is currently patent pending.

The namesake of the Tomtech system is Tom Richards, former president of Process Technology. Process Technology President Jody Richards says, “Tomtech represents my father's philosophy and passion for making things great. It’s fitting that the platform be named after him. Long after he retired, he was constantly bringing new inventions and ideas for improvements to our products. He would have been thrilled with this launch.”

Process Technology’s Tomtech heating system is expected to ship in the first quarter of 2023.

Related Content

-

Products Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

-

3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.

-

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.