Hardide Coatings Launches First Product in New Ready Coated Component Range

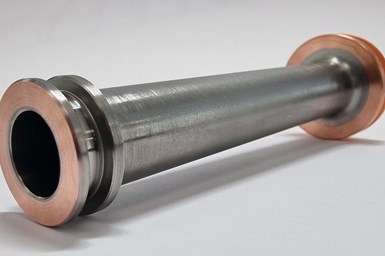

Hardide coated HVOF copper nozzle extends life by up to 40x.

Hardide Coatings, provider of advanced surface coating technology, has launched the first in a new range of ready coated and enhanced components with a JP-5000 4” copper nozzle used in high-velocity oxy fuel (HVOF) thermal spray coating.

The tungsten/tungsten carbide-based Hardide chemical vapor deposition (CVD) coating is proven to extend the operational life of HVOF thermal spray copper nozzles by 5 to 40 times when spraying carbide or metallic-based powders. The ready coated nozzles include O-rings suitable to withstand the higher temperatures generated in longer periods of service.

Steve Paul, interim CEO of Hardide Coatings, says, “This is an extremely exciting new product development which offers significant performance, cost and environmental advantages to users of HVOF equipment. By Hardide coating the internal diameter of copper nozzles used in thermal spraying, our enhanced component offers superior wear resistance and reduced pickup. The coated nozzle is the first in a range of Hardide ready coated copper nozzles of varying sizes and other OEM equipment which we intend to launch on an ongoing basis.”

The extremely hard and homogeneous properties of the coating minimize pickup inside the nozzle when spraying metallic materials. This prevents material dislodging and forming a defect in the HVOF coating, therefore improving coating quality, reducing downtime and the cost of spraying.

Moreover, the nozzle has to be exchanged less often which decreases the risk of breaking the water circuit, while lack of nozzle clogging reduces the likelihood of spits or unmelted agglomerations of powder becoming embedded in the spray coating, thereby eliminating the need for rework.

The Hardide coating is compatible with a range of coating materials used in HVOF processes, enabling seamless integration with existing coating systems, the company says.

Related Content

-

Robots, AI and Superb BMW Surfaces

There isn’t an automotive paint shop in the world that doesn’t have post-paint inspection and defect processing. But BMW is doing this with levels of technology at a plant in Germany that exceed all other paint shops in the world.

-

Curing Oven Basics

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...

-

Products Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.