Acquisitions Spur Lincoln Industries' Continued Growth

The acquisitions of Southwest Metal Finishing/Inventix Mfg. and SourceOne propels finishing giant.

2018 could be called a year of acquisitions for Lincoln Industries. In May, the Nebraska finisher purchased several affiliated Wisconsin-based businesses, including Southwest Metal Finishing, Inventix Manufacturing and Southwest Manufacturas De Mexico.

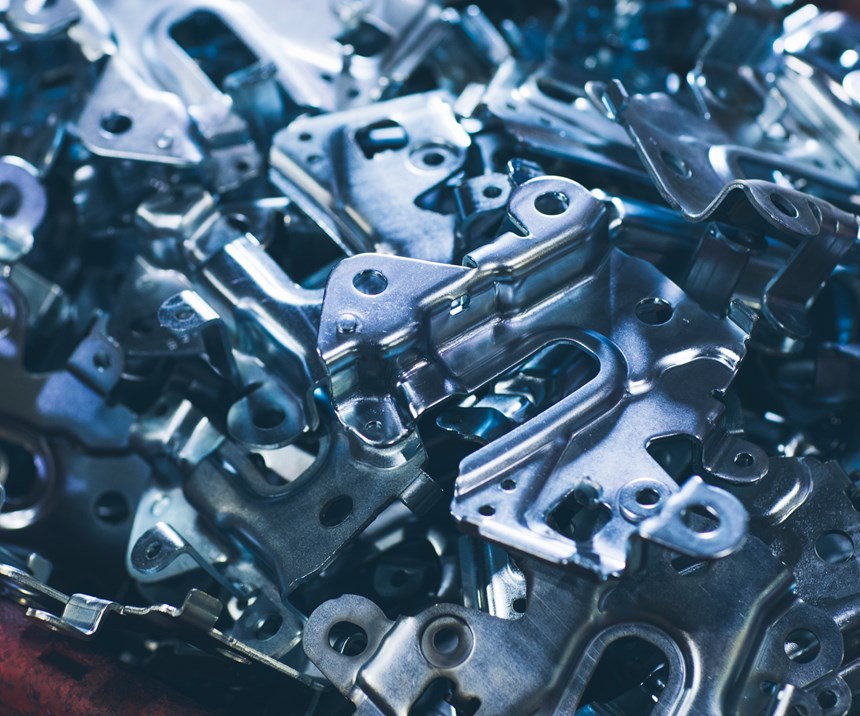

Southwest Metal Finishing in New Berlin was a decorative chrome plating and metal finishing company focused on zinc and aluminum die cast finishing, and also had facilities in Texas and Mexico with Southwest Manufacturas De Mexico, a polishing and plating operation. Inventix Manufacturing in Menomonee Falls produced zinc and aluminum die castings.

In September, they acquired SourceOne, a longtime nearby business in Nebraska, which provides industrial customers with a wide range of services, including custom manufacturing, design services and tooling, powder coating, and specialty machine build services.

Together, Lincoln Industries now employs more than 1,400 people. “The combination of our companies is driving substantial technological and operational synergies,” says Marc LeBaron, chairman and chief executive officer. “While we provide more than 40 finishing processes and significant manufacturing capabilities, the addition of zinc and aluminum die casting and related metal finishing processes in Wisconsin and the new business around powder coating, manufacturing and automotive machine design and builds will fuel growth for the company for the next decade.”

From Design to the Finished Product

Lincoln Industries’ locations have shared some of the same customers, but LeBaron says there is now added opportunities where the customer bases didn’t overlap. With all locations completely integrated, several opportunities await to provide a part from design to the finished product.

Clint Boothe, Lincoln Industries vice president of strategic accounts, has recognized a significant impact with 2018’s acquisitions.

“We have had interest from customers wanting to explore finishing aluminum or zinc die cast in the past, but we were apprehensive about offering finishing only,” says Boothe. “The quality of the cast material is extremely important to overall success. The Southwest Manufacturing acquisition presented an opportunity to get the casting operation, polishing and plating. Being able to control the supply chain of casting and plating has put us in the best situation to be a Tier 1 supplier.”

Additionally, Boothe is pleased with the improvements to Lincoln Industries’ polishing capabilities.

“Identifying polishing sources has been a challenge,” he says. “To be successful, we must be competitive in polishing, locally and nationally. We now have a world-class polishing operation that addresses current needs and positions us well for future growth.”

Improving Wisconsin, Mexico Locations

With growth at the forefront of their minds, Lincoln Industries has begun implementation of three capital projects between its Wisconsin and Mexico locations. The first was aimed at renovating a plating line that had previously been shut down in New Berlin.

“This project can be seen as an investment that has made a huge impact,” Boothe says. “Having this plating line operational will allow us the capacity to double the business with two of our top customers.”

The remaining two projects will take place in 2019 at Lincoln Industries’ Mexico location. One is focused on the expansion of steel polishing capabilities, while the other will be the implementation of plating on aluminum substrates. Boothe says both projects will help Lincoln Industries grow to a competitive advantage, increase capacity for more projects in Wisconsin and allow the opportunity for additional jobs.

“These three projects together open up capacity in Mexico and Wisconsin that will give us the capability to grow 50% without investing significant additional capital,” he says.

Largest Expansion in Company History

Over 10 years ago, the original footprint of Lincoln Industries’ tube fabrication facility was 20,000 square feet. Today, there is over 160,000 square feet with more than 50,000 square feet of growth opportunity. LeBaron says this expansion is due to Lincoln Industries’ growing truck business.

“We currently serve 100% of the over-the-road, heavy-duty truck manufacturers in North America,” he says. “When we first entered the tube fabrication business, we were producing 1,000 tubes a week. Our current volume is 10,000 per week, and will continue to grow with the increased nationwide demand for our products.”

Lincoln Industries’ capabilities are extensive, offering fabricated tube assemblies, ranging from simple designs to complex multi-axis configurations for carbon and stainless tube — from ⅜” to 8” in diameter and a full range of wall thicknesses. The process takes 20-foot-long steel or stainless-steel tubes and puts them through a series of operations, including tube bending, end forming, flaring, beading, expanding, swedging, brazing and welding.

Its tube fabrication takes place in both its Nebraska and Minnesota locations. Minnesota houses eight small tube benders, while large tube bending is done on one of four machines in its newest Lincoln facility.

LeBaron says that this thriving business unit — with tremendous opportunity for growth — started as a strategy to differentiate Lincoln Industries’ core business. In 2006, a potential customer presented Lincoln with a challenge they were facing — with governmental regulations and new environmental standards, they had thermal issues. A team at Lincoln Industries worked to design the product, aiming to reduce the temperature and meet the new standards, while maintaining its highly cosmetic look. The final product worked as a diffuser, pulling air into the product to cool it.

Entering Tube Fabrication

This project opened the doors for Lincoln to get into the tube fabrication business. Tim Carpenter, vice president of operations, says that, over the last 10 years, Lincoln Industries has evolved from doing only highly cosmetic work, to producing noncosmetic, functional tubing product for customers.

“Because of our prior performance and relationship with the customer, we were asked to get into the unfinished product,” he says. “That wasn’t part of our strategy originally. It’s a great example of the importance of one of Lincoln Industries’ beliefs — positive relationships build loyalty.”

Carpenter says incorporating tube bending into their operation allowed them to become vertically integrated.

“There is no better compliment than having one of your largest customers come to you because they want you to take on more,” he says.

To improve capacity and launch new opportunities with customers, Lincoln Industries sourced a new bender from Schwarze-Robotec in 2018. Tom Pryor, Lincoln’s director of engineering, says the bender is the largest, all-electric bender that Schwarze has produced and the largest, all-electric, stacking bender in the United States.

“It is quality and capacity, all in one bender and the team is excited to have it in our new facility,” Pryor says.

The new bender has the capability to bend every part that Lincoln Industries currently makes. Like its other benders, the operating systems are complex and require operators to complete 12-18 months of training prior to being certified to operate the bender.

“Our capabilities are far greater now,” Pryor says. “When we are given solution-based opportunities, we work actively to solve customers’ challenges.”

Lincoln Industries University

In 2018, Lincoln Industries aimed to establish a stronger foundation for the future development of its people by launching Lincoln Industries University (LIU). In addition to over 1,200 courses offered both online and in person through LIU, Outward Mindset training took place in Nebraska and Minnesota to enhance the culture and energize the beliefs and drivers. Training is set to take place in Wisconsin in 2019. New courses in Nebraska include Emerging Leaders, aimed to develop new and potential leaders and equip them with the knowledge and education to lead effectively, and English Language Learner courses.

Visit lincolnindustries.com

Related Content

How to Choose Between Sulfate and Chloride-Based Trivalent Chromium

There are several factors to consider when choosing between sulfate and chloride-based baths for trivalent chromium plating. Mark Schario of Columbia Chemical discusses the differences and what platers should keep in mind when evaluating options.

Read MoreProducts Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read MoreTrivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

Read MoreAn Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More

.jpg;maxWidth=300;quality=90)