Aerospace: Base Coat-Clear Coat System Offers Benefits for Aircraft

This system improves buffability and extends service life.

Share

New aerospace coatings technologies are making application more efficient and eco-friendly; enhancing performance by extending service life, offering better corrosion resistance, reducing weight and adding unique functionality, and affording more creative, longer-lasting options for liveries.

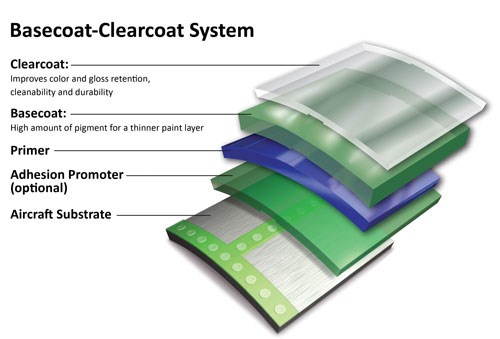

An exciting topcoat technology finding increased aerospace industry preference is the exterior base coat-clear coat system. Modeled after those that have become the automotive industry standard, base coat-clear coat topcoat systems comprise a heavily-pigmented base coat that provides more color with less paint than traditional coatings, saving material, weight and application time; and a high-gloss clear coat that extends service life, improves buffability and provides a smoother surface that is easier to clean.

Speeding-Up Cycle Time

Significant advancements have been made that reduce the time it takes to paint an aircraft. The primary driver of the exterior base coat-clear coat systems for OEMs is to create additional capacity by speeding the overall application time as production rates continue to increase. This is accomplished by faster-drying base coat technologies so that many colors can be applied in the time it takes one color to dry in traditional, direct-gloss systems. For airlines, reduced paint process time translates to reduced time for aircraft out of service.

Because of their many advantages, base coat-clear coat topcoat systems are replacing direct-gloss products for aircraft application at an accelerated pace. Application benefits are numerous.

Painting cycle process time is reduced, because the base coat is fast-drying and typically provides color with one coat instead of two or three coats common for traditional coatings. A full day can be saved in the painting cycle. The color coat dry time is about two hours, instead of five to 10 hours for most high-solids paints, because drying slowly is not required for a glossy, smooth finish when using a clear coat. Also, only about a half-hour dry time is needed after logo colors and placards are painted over the base coat before the clear coat can be applied, compared with about two hours for a traditional paint system. The clear coat can be applied up to five days after the base coat application, which allows for more process flexibility.

Easing Repair

These systems also are robust in a wide range of environmental conditions and are easily repaired during the painting process. The clear coat can be sanded and polished if defects need to be removed and applies well with application properties remaining consistent, without tending to run, sag or pinhole.

While OEMs are able to control the paint application environment, many maintenance, repair and overhaul paint shops often cannot. These coatings typically can be applied in temperatures ranging from 59 to 86°F, and relative humidity of 30 to 75 or 80 percent.

Saving Weight, Extending Life

In addition to greater application efficiency, base coat-clear coat systems offer weight savings for reduced aircraft fuel costs. Reduction in painted weight for base coat-clear coat systems compared with direct-gloss systems can be 15 to 25 percent, with darker colors being about 25 percent and lighter colors being about 15 percent. With each pound taken off a plane resulting in fuel savings, translated across a fleet, the cost savings can be significant.

The service life of aircraft exterior paint systems continues to improve with newer technologies while the requirements for gloss and color retention continue to increase. Paint systems of 20 years ago would not last more than a few years by today’s standards, but newer exterior coating systems are now lasting seven to 10 years, depending on the operational characteristics and the region in which aircraft are flown. More abrasive or humid environments will see less service life as compared with those regions that do not have such environmental issues which the coating system must resist. Clear coats can operate in temperatures ranging from -65 to 350°F.

Base coat-clear coat systems have much greater durability than direct-gloss systems, so the repainting cycle is extended by several years, which also reduces costs related to aircraft downtime and revenue loss. Increased paint durability and shorter repainting process time mean a plane won’t need to be repainted as often or be grounded as long for maintenance. An airline that loses revenue every day an airplane sits for repainting will therefore reduce those maintenance-related costs. Airplanes painted with base coat-clear coat systems also look better longer. Using a clear coat improves gloss and color retention as well as cleanability for a longer life.

Base coat-clear coat topcoat systems are finding increased aerospace industry preference. The heavily-pigmented base coat provides more color with less paint than traditional coatings, saving material, weight and application time.

Enhancing Color

Another aerospace coatings trend modeled after automotive coatings is the greater use of color and effects. As airlines strive to enhance their branding, the coating supply base has improved upon the ability to develop, produce and maintain new colors and special effects. The result is a greater range of aircraft liveries beyond the traditional white aircraft with few colors on the tail. The application of base coat-clear coat technologies and the efficiencies they deliver for more complex liveries has been a catalyst for greater differentiation.

Aerospace coatings have been developed with increased functionality, such as solar-heat management to reflect solar radiation and keep interior cabin temperatures and aircraft exterior skins cooler while aircraft are on the ground, and coatings that reduce aircraft drag for better fuel economy. Eco-friendly electrocoat primer application is now being used to provide aircraft parts with superior corrosion resistance and significant weight savings compared with traditional spray-applied application. E-coat also reduces primer application and processing time.

Perhaps at no other time have we seen so many aerospace coatings technologies developed and introduced at such a rapid pace. Opportunities continue to be presented, and aerospace coatings manufacturers continue to take up the challenge.

Mark Cancilla is global director for Aerospace Coatings for PPG Aerospace - Deft

Originally published in the December 2015 issue.

Related Content

Finishing High Reliability, Function Critical Parts

From safety critical automotive and aerospace components to lifesaving medical micro-components and implantable devices, Indiana-based Electro-Spec finishes applications that require zero failure rates.

Read MoreTop Shop’s Journey to Building a Unique Brand

Since this new Ohio plater took over the space and assets of a former plating business, it is intentional about setting itself apart from prior ownership.

Read MoreAnodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.

Read MoreAdvancing Aerospace Connectors

OEMs looking to optimize aircraft performance and range are turning to composites and plastics, which require specific finishing treatments.

Read MoreRead Next

Masking Solutions for Medical Applications

According to Custom Fabricating and Supplies, a cleanroom is ideal for converting, die cutting, laminating, slitting, packaging and assembly of medical-grade products.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More