Aluminum Burnishing/Brightening

How can we eliminate damage to aluminum parts finished in a vibratory machine with steel ball-cone media?

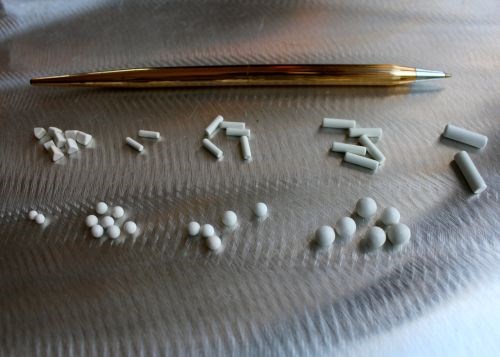

Q. We produce an aluminum motorcycle taillight housing that requires brightening. Our current finish process is a 1-hr cycle with a 3/8” steel ball-cone media in a vibratory machine. It brightens the parts, but leaves small scratches and dings on the surface. What would you recommend to eliminate the damage?—M.E.

A. Steel media works well for burnishing parts. It is polished, cased-hardened and produced in many shapes and sizes. The steel media also runs approximately 65 HRc, which is much harder than your aluminum parts.

The vibratory machine should be set to a gentle action with the amplitude setting between 2 and 3 mm. A burnishing soap compound with slight foaming and good lubricants will cushion the mass, reducing media damage. A flow-through compound system will help stabilize the process.

If part damage is still a problem, try a different media. A mix of 3- and 4-mm porcelain balls with the right burnishing compound produces a higher luster and eliminates media damage on aluminum. The porcelain balls will weigh 100 lbs/cu. ft., which is much less than the 300 lbs/cu. ft. of the steel media. Heavier media can damage softer metal alloys.

Related Content

-

Calculating Applied Media Force During Vibratory Finishing

What appear to be identically set-up vibratory bowls will finish identical loads of parts in varying time cycles. This paper offers a new technique to better predict what the operator will produce, by measuring the force applied to the parts. It is the efficiency of that force which controls the efficiency and speed of the refinement cycle.

-

Understanding Shot Peening

A look inside shot peening — a process of “hammering” of work pieces with precisely defined blast media.

-

Vulkan Blast Shot Technology

Vulkan Blast Shot Technology is a pioneer in the stainless steel abrasives market.

.jpg;maxWidth=300;quality=90)