Best Practices for Industrial Paint Storage

Sponsored ContentWhether it’s paint, powder or other surface finishing materials, it is critical to handle chemical substances properly for the safety of your shop and employees. Here are the best (and worst) ways to store hazardous and nonhazardous materials.

Share

Whether it’s paint, powder or other surface finishing materials, it is critical to handle chemical substances properly to protect your employees, facility and overall finishing process.

Failure to consider safe material storage can lead to quality issues, wasted costs in material and serious health risks. By taking a closer look at quality and safety standards, businesses can better optimize their entire finishing process for consistent quality and a safer work environment.

Know Your Materials

Powders, paints and other chemicals can present safety risks, and often require specific environmental conditions to protect the quality and effectiveness of the material. Some materials are more sensitive to conditions such as temperature and pose certain threats when stored with other chemicals. Other materials can be stored long-term in bulk inside a separate storage room and do not require extra safety measures.

Powder coatings, for example, must be stored in a cool, dry environment—with temperatures below 80 degrees and humidity levels less than 50 percent. Since it is hygroscopic, powder easily absorbs liquid, and excessive humidity can cause powder to clump or cake. On the other hand, excessive dryness can cause problems with electrostatic application. This type of sensitivity can compromise the quality of the powder itself as well as the end product after powder coating.

In addition to powder, industrial liquid paints can be affected by extreme temperatures, which can have a significant impact on quality and shelf life. Water-based paints, for example, may begin to gel when stored at temperatures below freezing, but when stored at higher temperatures, they can also develop an unfavorable consistency. These extreme environments can cause paint to drastically change its viscosity or lead to settling of residue or pigments that can negatively impact the paint’s performance.

Safety Considerations

Surface finishers must always be aware of hazards associated with flammable, combustible or explosive materials. This includes everything from atomized liquids or solvents to high concentrations of powders or dust.

Some materials, often found with powders, possess combustible properties. In their atomized state during the spray application, powder coatings can be fuel for a deflagration (a type of fire or explosion). Solvent-based paints pose health and safety hazards associated with harmful vapors and toxins released into the air. Chemicals such as thinners, cleaners, adhesives, gloss and polishes can also be flammable or combustible, thus the storage of these materials must not be taken lightly.

| The hazardous material storage building pictured here is used for storing and pumping industrial paint. |

Organic and metal dusts can be ignited and create a deflagration when dispersed in the air. These materials may not be considered combustible under normal conditions, but the right combination of particle size, concentration and presence of an ignition source can cause deflagration.

To better understand the safety hazards of your coatings and other hazardous materials, start by reviewing the Safety Data Sheet provided by your supplier, or directly consult your supplier for questions on chemical properties and associated hazards. The International Building Code (IBC), National Fire Protection Association (NFPA), Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA) and other regulatory agencies can further specify code compliance and storage requirements.

The Safety Data Sheet can answer questions such as whether a chemical is:

- Combustible

- Corrosive

- Flammable

- Light sensitive

Or if it requires:

- Identification

- Segregation

- Special handling

- Temperature control

- Ventilation

Furthermore, the chemical composition of your material may pose certain hazards when stored with incompatible materials, so it’s important to understand how your material behaves with others used in the facility.

Paint Productivity

Every industrial environment can benefit from good material storage habits. By using your materials more efficiently, businesses can gain significant savings by minimizing waste.

This starts by eliminating the amount of material that is lost by spills or compromised by contamination. Contamination—in the form of atmospheric contamination—can be caused by residuals in the plant air or cross-contamination when working with multiple materials. Contamination not only leads to poor finish quality but can also result in issues with the finishing equipment.

Second, shops can cut costs by storing and reusing leftover materials like primers and basecoats. And lastly, for shops growing quickly, equipment like hazardous material storage buildings help keep up with production demands and reduce the number of times a shop needs to restock. Properly storing materials not only prevents waste, but it also prolongs shelf life, furthering long-term productivity gains and decreasing shop costs.

The Cost-Saving Solution

One of the top reasons that shops are deterred from looking at better hazardous material storage options is cost. This leads many to take shortcuts or find cheaper alternative solutions. Even the most experienced businesses may be unaware of potential cost savings, and some may purchase less expensive storage methods without knowing the risks.

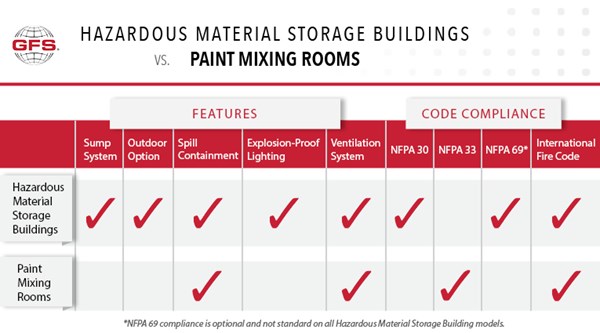

One mistake is using a paint mixing room in place of a hazardous material storage building. Solvent-based paints can be stored in paint mixing rooms, but only in small amounts—no more than 2 gallons per square foot. Paint mix rooms contain many of the same features of hazardous storage rooms, such as spill containment and ventilation; however, paint mix rooms are designed to meet compliance for paint mixing—not for storage of large amounts of hazardous materials.

Fortunately, the actual cost of properly storing and handling materials is far less than the cost of code compliance penalties, wasted product and potential safety disasters.

Hazardous Material Storage Buildings from Global Finishing Solutions (GFS) offer a cost-effective solution, designed for safe storage of large amounts of paint, powder or other hazardous materials. In addition to providing a safe, code-compliant environment for paint and chemical storage, Hazardous Material Storage Buildings also double as a safe area for mixing and pumping paint.

Here are the top four ways these buildings cover all of the material storage needs and requirements:

1. Safe Storage

GFS Hazardous Material Storage Buildings are designed with explosion-proof incandescent lighting and external grounding to prevent static ignition. These buildings not only minimize the risk of deflagration but reduce hazardous exposure for a safer working environment.

2. Code Compliant

Hazardous Material Storage Buildings are designed to meet industry safety standards and comply with applicable International Fire Code and NFPA 30—Flammable and Combustible Liquids Code for the storage of chemical products. Additional building compliance alterations are available, so the buildings can properly meet required codes and standards. The rooms feature bidirectional fire-rated design and provide deflagration control.

|

Hazardous Material Storage Buildings |

3. Spill Containment

The sump system is made of liquid-tight, heavy-gauge sheet steel and supported by exterior-welded steel risers for easy leak inspection. Spills enter the spill containment tray through one-inch-thick, black painted steel grating that runs the entire length of the enclosure and is supported by six-inch steel beams for added stability.

4. Custom Solutions

GFS provides customers with custom engineering and specialized products with options such as dry chemical or water sprinkler systems, custom sizes, heaters and air conditioning units, deflagration panels and ramps that can be integrated seamlessly into the building’s design. Shipped completely assembled, the storage buildings are easily installed, portable and designed for either indoor or outdoor applications.

Learn more about Hazardous Material Storage Buildings from Global Finishing Solutions.