Cool Clean Technologies Has A Hot IMTS

Snow cleaning uses solid CO2 particles to clean the surface removing fingerprints, contaminants, and light oils without causing any damage to the part.

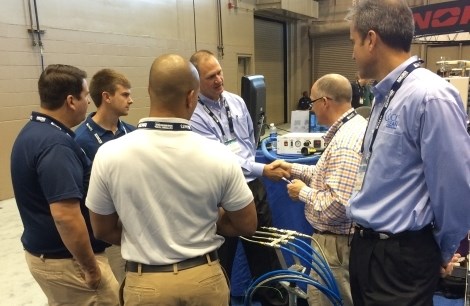

One of the hottest booths at IMTS this year had a very “cool” process as Cool Clean Technologies introduced its new cleaning technologies utilizing environmentally friendly CO2.

Snow cleaning uses solid CO2 particles to clean the surface removing fingerprints, contaminants, and light oils without causing any damage to the part. Liquid CO2 (LCO2) cleaning uses a different approach. Parts to be cleaned are placed in a wash vessel kept at high pressure enabling the CO2 to remain as a liquid. LCO2 cleans all around the surface and inside the part in areas difficult to reach with water based cleaning.

All of Cool Clean Technologiesprocesses are waterless, chemical-free, and designed to save customers on time and money. For more information, please visit CoolClean.com

Related Content

-

Advantages to Pumped Eductor Agitation

Not all agitation methods are created equally. Pumped agitation with eductor nozzles can improve process tanks and quickly show a reduction in operating costs while keeping staff safe, following environmental legislation and preventing pollution.

-

TTX Environmental Solves Customer Issue with Electro-Ceramic Desalination Wastewater Processing

Electroplating facility without access to a drainage system found a safe solution for wastewater treatment and reuse.

-

Top Reasons to Switch to a Better Cleaning Fluid

Venesia Hurtubise from MicroCare says switching to the new modern cleaning fluids will have a positive impact on your cleaning process.

.jpg;maxWidth=300;quality=90)