TTX Environmental Solves Customer Issue with Electro-Ceramic Desalination Wastewater Processing

Sponsored ContentElectroplating facility without access to a drainage system found a safe solution for wastewater treatment and reuse.

An electroplater building a new facility in Queretaro, Mexico, discovered that their new facility did not have access to a drainage system and approached TTX Mexico and TTX Environmental for assistance. The electroplating lines were expected to produce wastewater at a rate of 80 gallons/minute and contain hexavalent chrome, cyanide, zinc, nickel, oils and grease, and suspended solids. TTX Environmental investigated options and determined that water treatment followed by water reuse was the most practical solution for the application. It was determined that TTX’s industrial flow-through wastewater treatment system could remove contaminants to a safe level through hydroxide precipitation. However, additional equipment would be required in order to achieve the necessary water quality required to reuse the treated water in the electroplating processes. Partnering with Membrion, an electro-ceramic desalination process was identified as a solution to recover large fractions of the wastewater.

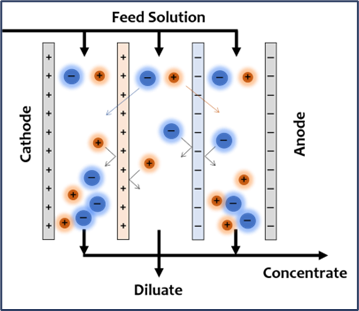

Figure 1: Electro-Ceramic Desalination Process.

Source: TTX

Electro-ceramic desalination (ECD) employs alternating cationic and anionic selective membranes. When an electric field is applied, ions are driven across the membranes, leaving ionically-free water behind. Traditional desalination membranes are constructed of polymer membranes and quickly foul and form permanent scale. Membrion’s technology employs ceramic-based membranes which can operate in the harsh environments associated with wastewater streams. These unique membranes can overcome common fouling and scaling conditions utilizing polarity reversal. The polarity of electrodes and the flow paths are switched so that the concentrate path is flushed with dilute water driving foulants off the membrane surface thus extending membrane life.

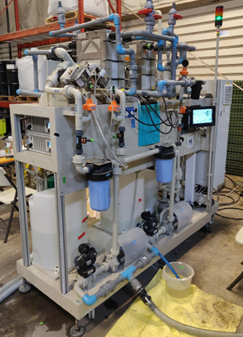

Figure 2: Electro-Ceramic Desalination Pilot System.

Source: TTX

To determine feasibility of the ECD process for this application, bench-scale testing was performed first. Bench scale testing using a small scale ECD module resulted in an 89% reduction in conductivity while recovering 93% of the feed water. To confirm bench test results and evaluate commercial viability, an on-site pilot study was then conducted. Additional objectives included validation of operating parameters, sizing full-scale equipment, determination of frequency and effectiveness of cleaning, confirmation of effluent water quality and recovery, and identification of any pretreatment or post treatment requirements.

Pilot testing was conducted over a two-week period at the electroplater’s facility. Effluent from the existing wastewater treatment system was fed into the ECD pilot system. The conductivity of the incoming water ranged from 1800 to 3900 µS/cm. The corresponding product water quality and water recoveries are summarized in Table 1 below.

| Incoming Conductivity (µS/cm) | Product Water Conductivity (µS/cm) | Water Recovered (%) |

| 2200 | 800 | 96.5 |

| 1800 | 840 | 98 |

| 2200 | 773 | 97.6 |

| 3800 | 1054 | 90.6 |

| 3900 | 993 | 91 |

| 3400 | 883 | 93.1 |

Table 1: Summary of Pilot Testing Results.

Upon completion of the pilot study, analysis of the collected data was performed and applied to an operation-scale design. The operation-scale system is expected to produce water with a quality of less than 900 µS/cm at a recovery rate of approximately 94%. The operation-scale system is currently in production.

Are you wasting dollars and valuable resources by dumping wastewater to drain? Are you struggling to effectively treat wastewater? Contact TTX to see if a water recovery system is right for you.