Electropolishing as a Pretreatment for Anodizing

Electropolishing can be a pretreatment for anodizing or a substitute for bright dipping. Either way, it improves the surface of the aluminum...

Share

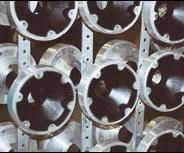

Electropolishing is the electrolytic removal of metal in a highly ionic solution by means of an electrical potential and current or, in other words, reverse electroplating. So what are the benefits of using electropolishing as part of an anodizing process? Plenty, as Fort Wayne Anodizing has found out. Not only does electropolishing provide a decorative surface and act as a replacement for bright dip, it improves the aluminum surface prior to anodizing by smoothing out the peaks and valleys.

Electropolishing removes metal from the surface while producing a unidirectional pattern that is stress and occlusion free, microscopically smooth and highly reflective. Deburring is accomplished quickly because of the higher current densities used, enabling the constant exposure of the burr tip. The combination of no directional lines from mechanical finishing, plus a surface relatively free of hydrogen, results in a hygienically clean surface.

Electropolishing aluminum does not produce toxic fumes, require fume hoods, produce corrosion or require high temperatures. To control the bath, FWA takes the specific gravity and checks the aluminum metal content.

"We see it as a big advantage over bright dipping," stated Dennis Fulford, sales manager. "Bright dipping aluminum produces nitrogen dioxide, which is toxic. Also, you have to run the bath at a higher temperature (194-205F), which requires more heat and hence more money. Another issue is that the bright dip bath has several variables that need to be controlled in order to produce good work."

Neither is an aluminum electropolishing bath the same as a stainless steel electropolishing bath. Chemistries as well as parameters differ. See Table I.

However, much like their steel counterparts, aluminum pieces are cleaned prior to electropolishing. Aluminum parts first go through degreasing, unless they are heavily soiled, in which case they are etched. FWA tries to avoid this as much as possible because the etching can mar the surface of the aluminum. After degreasing and rinsing, parts are desmutted and run through more rinses before entering the electropolishing tank. After electropolishing, parts are rinsed and run back through the desmut tank to clean off any oils they may have picked up in the rinse tanks. Now they are ready for either conventional or hardcoat anodizing.

FWA offers both conventional anodizing, as well as hard coat anodizing, chromate conversion coating, vacuum impregnation and the Metabrite Process. The customers who have requested the electropolishing have been mostly from the medical field, appliance and heavy truck industries. Many want the bright electropolish with an anodized and clear finish for items such as headlamp bezels, side mirror brackets and grilles. The medical industry requests the process because of how well it removes burrs, which is extremely important when dealing with surgical equipment. These items are also dyed. FWA has eight standard colors it offers from black and clear to purple and yellow. Some of the medical equipment is color-coded.

Fort Wayne Anodizing's slogan is "It's not how it's made. It's how it's made to last." And now it offers its customers one more way to make their products last longer and look better. "Traditionally, our customers relied on FWA to provide them with a matte or stain finish. With the electropolish, we can give them more options for a brighter anodize," stated Mr. Fulford.

Related Content

Trivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

Read MoreAnodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.

Read MoreUnderstanding PEO Coatings

Using high-speed cameras and back side illumination (BSI) sensor technology to analyze plasma electrolytic oxidation.

Read MoreRead Next

Masking Solutions for Medical Applications

According to Custom Fabricating and Supplies, a cleanroom is ideal for converting, die cutting, laminating, slitting, packaging and assembly of medical-grade products.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More