A Focus on Aerospace

Products Finishing looks into how coaters and finishers enable the aerospace industry, what trends and technology are emerging and more in February 2021.

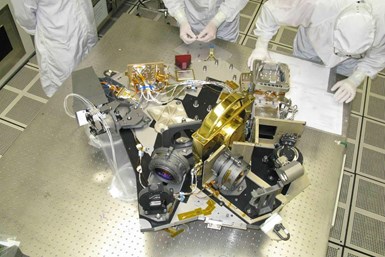

The James Webb Space Telescope’s NIRCam components rely on Epner Technology’s Laser Gold for thermal control. Photo Credit: NASA

The February 2021 issue of Products Finishing is now available. In this issue, we take a look at the aerospace sector and offer insights for how finishers and coaters can make the most of their systems.

Here are a few of the stories you’ll find inside:

- Gold plating enables the James Webb Space Telescope, which is scheduled to launch in October of this year.

- An innovated film measurement system is being used to investigate ways to improve aerospace finishes.

- New software from Paperless Parts helps Reata and Global Metal Finishing close the quoting gap between job shops and finishers.

- Measuring the conductivity in a hard chromium plating bath can help optimize its performance.

You’ll also find technical articles and Ask the Expert clinics offering best practices and troubleshooting. As always, the issue includes insightful columns and the latest news and innovations in the surface finishing industry. Don’t miss On the Line with Sheila LaMothe, executive director for the CCAI Finishing Education Foundation.

If you have a story that might be of interest to a wide audience of coaters of finishers, get in touch with editor in chief Scott Francis at sfrancis@pfonline.com.

Related Content

-

Top Shop Savors Past 20 Years of Prosperity

This one-stop finishing shop was rescued by new management in 2004. Since then, its rejuvenation has brought substantial growth and success to the business.

-

Advancing Aerospace Connectors

OEMs looking to optimize aircraft performance and range are turning to composites and plastics, which require specific finishing treatments.

-

NADCAP Shop Digitizes to Eliminate Paper Trail

Customizable ERP software has transformed a 27-year-old manual metal finishing job shop into a state-of-the-art paperless company with full digital traceability in about 10 months.

.JPG;width=70;height=70;mode=crop)