Heat-exchange maker Enerquip of Medford, Wis., used to take hours to polish stainless steel pipes using an older lathe equipped with a polishing head. The company knew it was a slow and undependable process, and that no spare parts were available if something should break.

That all has changed since Enerquip installed a special two-head OD polisher built by Grinding and Polishing Machinery of Indianapolis, Ind., a specialist in designing and building industrial grinding and polishing machinery.

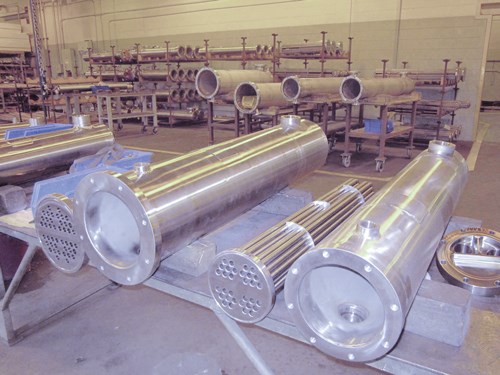

Enerquip uses the stainless pipes for the sanitary-grade shell and tube heat exchangers it designs and manufactures for the food, dairy, beverage, pharmaceutical and biotech industries in the U.S. and internationally. They now can be polished four times faster with the new G&P 90 Series Swing Frame Polisher compared to the two-headed abrasive belt grinder.

The machine includes two abrasive belt grinders that traverse the length of pipe powered by a 15-hp TEFC three-phase motor operating at 3,600 rpm. A 6-inch diameter drive pulley and 10-inch diameter by 6-inch wide contact wheel drive each belt at 5,500 sfpm. A variable-speed AC-drive carriage traverses the belt heads along the pipe.

The 90 Series Swing Frame machine also includes a tailstock and steady rest assembly, each with floor casters and an air-locking device. The tailstock also features steel centering cones for a range of pipe diameters, and operator controls are mounted in front of the polishing heads for ease of access and visibility.

Enerquip uses pipes ranging to 20 inches in diameter and 22 ft in length, with most jobs requiring from 4- to 12-inch nominal pipe size in either 5- or 10-gauge stainless steel (0.109-inch wall and 0.188-inch wall).

According to Quality Assurance Manager John Barna, the outside of the pipe is polished before construction of the heat exchanger begins to provide an attractive finish. Later, the pipe is cut to length, and a tube bundle assembly, heads and various other components are installed.

The new polisher has made a big difference to Enerquip, according to Barna, who says it previously took 60 to 90 minutes to polish a 20-ft length of 8-inch-diameter pipe.

“We were depending on the machine on a daily basis, and if something went down, we couldn’t get the parts to rebuild it,” he says.

With the G&P grinder, Barna says it now takes only about 15 minutes to polish that 20-foot length of 8-inch-diameter pipe.

“Quality is consistent, and our worries about production delays have ceased,” Barna says. “The new machine has improved productivity to the point where we have enough capacity to take on outside polishing jobs in addition to our own work.”

For more information on Grinding and Polishing Machinery, please visit GandPmachinery.com

Related Content

-

Advanced rotary surface grinders now come “robot-ready” to facilitate integration with third party robotic arms and fully automate the process from loading to unloading.

-

Kennametal adds noise-reducing Blast Ninja to portfolio of abrasive blast nozzles.

-

Wall Colmonoy welcomes Josh Gardner as its business development manager of surfacing products.