Growing the MDF Powder Coating Market

Over the last 15 years, DVUV has overcome a number of challenges, including the variables inherent within the MDF substrate not typical of conductive metal substrates.

It was in October 2000 that DVUV—then known as Decorative Veneer—broke ground for a powder coating operation in Plainwell, Michigan, adding 10,000 square feet to its 30,000-square-foot facility to accommodate a UV-cured powder coating application system from Nordson Corp.

The new system began production in April 2001, making Decorative Veneer the first UV-cured powder coating on medium density fiberboard (MDF) installation in North America.

Decorative Veneer moved to the Cleveland area in 2005, changing its name to DVUV. A year later, the company established offshoot Keyland Polymer UV Powder, LLC to develop, formulate and manufacture UV-cured powder coatings for MDF, plastic, composite, ferrous and nonferrous metals for DVUV as well as other customers.

Over the last 15 years, DVUV has overcome a number of challenges, the biggest being one that all MDF powder coaters have had to face: identifying—and then overcoming—the variables inherent within the MDF substrate that are not typical of conductive metal substrates.

These variables include moisture content, density profile, material composition and machinability of the MDF board. Optimum moisture content is typically between 4–7 percent and needs to be controlled throughout the entire process. Consistency of MDF is the most critical factor, and DVUV works with high quality MDF board manufacturers such as Plum Creek, which works to ensure a high quality MDF substrate machined to tight tolerances using sharp routing tools that eliminate or reduce the need for edge sanding or other processing.

Decorative Veneer was the first UV-cured powder coating on medium density fiberboard installation in North America.

Building Awareness

Although it is not new to the powder coatings market, DVUV continues to build market awareness and acceptance of UV-cured powder coating. The benefits of UV powders are numerous, beginning with faster cycle times than thermal (IR and convection) cured powders. Additionally, UV powder ovens and lamps are energy efficient, and UV powder is environmentally friendly.

One of the first UV-cured powder systems for conductive substrates was installed at Baldor Motors in Westville, Oklahoma, in the mid- to late-1990s for powder coating and UV-curing of completely assembled motors. Several powder companies were heavily promoting UV curable powders for MDF throughout the 1990s and early to mid-2000s. However, for all of its process-efficient, cost-effective and environmentally friendly benefits, market acceptance has been slow to take hold for UV curable powder process technology. DVUV attributes this delayed market acceptance to challenging global and domestic economic events that have occurred since 2000.

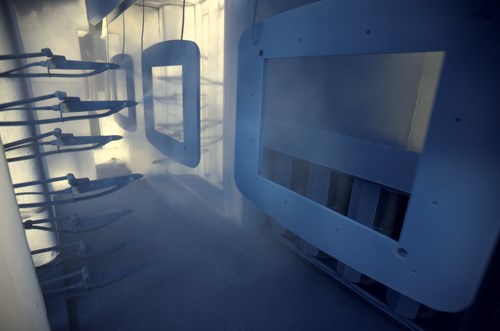

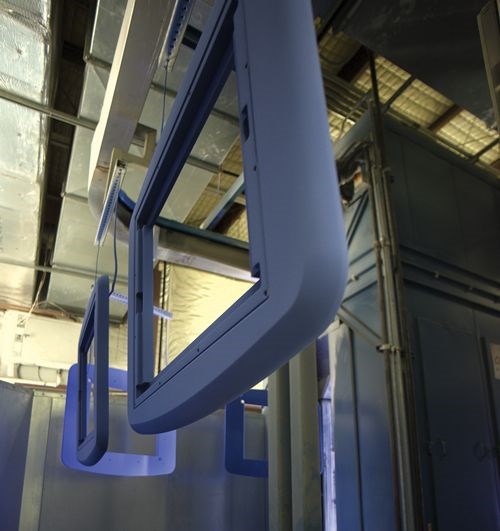

In total, DVUV and Keyland Polymer employ about 20 people. Total combined revenue is roughly $4–$5 million. DVUV, the MDF side of the business, uses about 15,000 square feet and its UV-cured powder system finishes a part in 20 minutes, a process that includes a 1-minute IR/convection preheat followed by coating in a fully automatic Nordson Excel 2000 powder coating system with an iControl automatic gun controller.

Optimum moisture content is typically between 4–7 percent and needs to be controlled throughout the entire process.

The Nordson application gives DVUV the capability to precisely control the application of powder, eliminating any need for manual reinforcement. Once the powder is applied, it is melted in an IR/convection oven for 1 minute and then instantaneously cured by 600-watt UV lamps. Separation of the melt/flow and cure is the key differentiating characteristic of UV-cured powder coating.

DVUV can finish MDF parts as large as 108 inches long, 60 inches wide and anywhere from ⅜ to 1½ inch thick. The system can also accommodate 3D MDF assemblies up to 7 inches wide. The finished parts cool as they make their way to the manual unload station, where they are unloaded, inspected and staged for packaging.

Repetition

Quality and production repetition is integral to DVUV’s success. Precise control of UV-cured powder application, responsive and accurate oven control, fast and low preheat and melt/flow and a certain cure from the UV lamps gives DVUV a first pass process quality of better than 99 percent.

Keyland Polymer covers a little less space—about 10,000 square feet—and is located in a building next to DVUV. Keyland’s business includes development of resins for UV-cured powder coatings, and to that end, Keyland currently employs two full-time chemists for daily operations, and two consulting chemists for resin development.

DVUV and Keyland Polymer currently employ about 20 people. Total combined revenue is roughly $4–$5 million.

Keyland’s sole focus is developing performance and product-specific UV-cured powder coatings for MDF and other materials, including plastics, composites, ferrous and nonferrous metals. The company can perform a full range of material performance testing in its lab and also has a demonstration system for product development on 3D parts, and a wire and cable coating line for continuous wire substrates.

Keyland is continuously improving its coatings through R&D efforts that center on resin development, powder coating additives and powder application. The company continues to improve powder coatings for both MDF and other substrates by concentrating efforts on key characteristics such as performance durability and smoothness of UV-cured powder coating finishes. They have developed and have commercially available a UV-cured powder coating that passes the ASTM B117 1,000-hour corrosion test.

Emerging Market

Over the years, DVUV has thrived in the still-emerging UV-curable powder market. This growth is thanks, in part, to its dedication to adding capabilities such as resin development, powder coating manufacturing and UV-cured application systems design and engineering.

As market acceptance is taking hold, UV curable powders are proving to be a cost-effective, energy-efficient and environmentally friendly alternative to solvent liquid and thermal cured powder coatings.

Information in this story provided by Nordson Corp. and DVUV. For information, contact Nordson at nordson.com, and DVUV at dvuv.com.

Originally published in the July 2015 issue.

Related Content

An Altruistic Growth Strategy Puts People First

Professional Plating emphasizes investing in its team and fostering a supportive environment on the shop floor.

Read MoreSelecting the Right Outdoor-Durable Powder Coating

The powder coating industry offers an array of chemistries to provide an excellent match to the manufacturer’s expectations for outdoor durability.

Read MoreMasking Solutions Provider CFS Dramatically Expands Capabilities and Capacity

Custom Fabrication & Supplies (CFS) completed a new plant expansion packing 10 times the capacity into twice the space. It dramatically enhances the supplier’s custom capabilities to provide extremely precise and cost-effective masking solutions.

Read MoreProducts Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More