PM tasks include visual inspections of moving components, scheduled cleanings, lubrication, and so on. Every reputable manufacturer of ovens and furnaces provides a maintenance manual for their equipment, which includes guidelines for these activities. Photo Credits: Wisconsin Oven Corp.

An effective preventative maintenance (PM) program is the backbone of every well-functioning manufacturing operation, ensuring equipment reliability, reducing downtime, and ultimately enhancing productivity. In this article, we will explore the key benefits of implementing a robust maintenance strategy for industrial heating equipment, such as ovens, furnaces, and related equipment.

Simply put, PM is a scheduled routine of planned actions with the goal of preventing breakdowns and failures before they occur. PM tasks include visual inspections of moving components, scheduled cleanings, lubrication, and so on. Every reputable manufacturer of ovens and furnaces provides a maintenance manual for their equipment, which includes guidelines for these activities. If your equipment supplier didn’t provide a written program, you should not have much trouble establishing a PM program. With a little effort, you will find numerous articles on how to maintain your equipment, what to maintain on your equipment and when to perform maintenance.

It is not unusual for PM to be neglected, until there is a catastrophic failure that causes seriously painful and costly downtime. After such an event, receiving funding for the time and money necessary is possible, but the goal is to perform the maintenance prior to a failure, to prevent it from occurring.

Looking at the “why” will help those controlling the purse strings of your organization understand how the costs associated with an established PM program can be compared with the long-term benefits and related savings.

Most of the information in this article can be applied to any industrial equipment. However, the emphasis of this article will be targeted at industrial heating equipment.

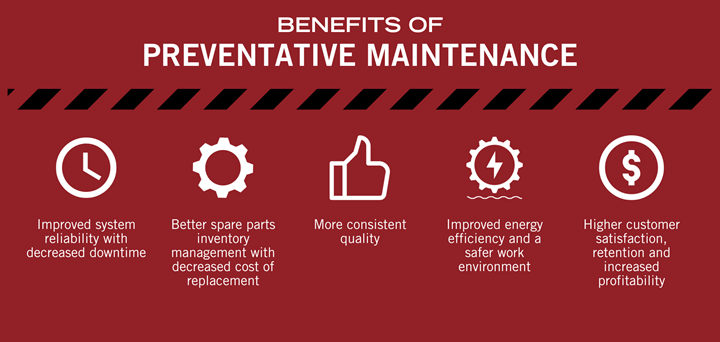

Some of the long-term benefits of a PM program include:

- Improved system reliability with decreased downtime

- Better spare parts inventory management with decreased cost of replacement

- More consistent quality

- Improved energy efficiency and a safer work environment

- Higher customer satisfaction, retention and increased profitability

Improved system reliability with decreased downtime. Maintenance and inspections planned outside of normal work hours do not negatively impact production. However, unscheduled equipment breakdowns will typically result in substantial costs associated with lost production time, late deliveries and expedited service and parts to get the equipment up and operational again, as well as the indirect costs of disappointed customers and lost employee work hours.

The long-term benefits of preventive maintenance for ovens can also be applied to most other manufacturing equipment.

Better spare parts inventory management with decreased cost of replacement. Companies with established PM programs can better anticipate what parts they need and when they will need them. Depending on the equipment and the product, you may still want to stock long-lead and/or critical components, but eventually, you will find that you do not need to keep non-essential components in stock. Stocking fewer spare parts increases inventory turns and improves cash flow. Often, routine inspections will uncover components that will need to be replaced in the future. Maybe the motor is beginning to vibrate a little more than usual, which can indicate the bearings might need to be replaced. If this is noticed early enough, the maintenance department can purchase the required components without paying expediting charges, and they’ll often be able to schedule maintenance during regularly scheduled work hours (read: no overtime costs).

More consistent quality. Equipment that is operating optimally will provide more consistent and higher quality parts. Over time, the temperature accuracy of industrial ovens, as well as the uniformity of the temperature throughout the work chamber, can deteriorate. Parts not processed at the correct temperature may not meet the expectations or requirements of your customers. Most often, part failures are not discovered immediately, and therefore many substandard parts are produced prior to discovery of the issue. As a result, entire batches may need to be recalled or re-inspected. This can be very costly and permanently damage business relationships.

Performing regular temperature uniformity surveys will allow you to maintain control over your heating process and the quality of your product. This will give your sales department the confidence it needs to make the next big sale.

Improved energy efficiency and a safer work environment. Adjusting the exhaust blower for the proper rate, making sure all filters are clean and that your gaskets are sealing properly are all huge energy savers. For instance, if you have a gas-fired oven, a properly adjusted and cleaned burner can reduce your gas consumption by as much as 5% to 15% when compared to a burner that hasn’t been maintained. This is a frequent culprit because the performance decreases slowly over time, going unnoticed, as dust and airborne contaminants build up, and the PID control self-adjusts the burner to compensate for the reduced performance.

In many cases, an oven that is not kept clean can be a safety concern. The buildup of residual combustible materials released during incomplete combustion might ignite, which is obviously something you want to avoid at all costs. Also, as an exhaust blower becomes dirty and its performance decreases, it may no longer exhaust sufficient air volume to remove the products of combustion. This can lead to carbon monoxide buildup in the oven and surrounding area, which is a personnel hazard. Inadequate exhaust can also lead to insufficient purging prior to ignition, which can cause a fire or explosion.

Higher customer satisfaction, retention and increased profitability. The culmination of these items helps keep current customers happy and helps improve profitability. It is well known that it costs much more to find new customers than to retain current customers. If you keep current customers happy, the sales department will have more time to secure new business at the proper sell price. Equipment that is well maintained will last longer and have a higher resale value.

Now that you have a better understanding of the benefits of a structured PM program, do you have to do it yourself? The answer is no! Contact the manufacturer of the equipment, or a different oven manufacturer to see how they can help. Most reputable oven companies offer PM as a service and discounted prices if you sign up for regularly scheduled visits. Some even service competitor’s equipment. Considering the benefits of smoothly running equipment and the high cost of downtime, most well-managed companies have an established schedule of (annual, bi-annual, or quarterly) visits contracted with their oven suppliers for this purpose.

Aan industrial IoT (internet of things) system is a new technology that can take a PM program to the next level. The most advanced suppliers of ovens and furnaces now offer IoT systems on their new equipment, and some offer retrofits for existing equipment. These systems continuously monitor the health of your heating equipment by sensing and measuring critical operating variables, such as vibration, chamber pressure, SCR output, temperature controller output, and more. This information is continuously transmitted to the cloud using cellular technology for retrieval by the oven manufacturer. By tracking these variables remotely, the equipment manufacturer can predict failures before they occur. The manufacturer can then contact you to offer a tune-up, a cleaning or replacement parts, avoiding costly downtime.

Now is the time to start. Put together your PM program today for a more profitable tomorrow.

About the Author

Mike Grande

Mike Grande has a 30-plus years experience in the heat processing industry, including ovens, furnaces and infrared equipment. He has a B.S. in mechanical engineering and received his certification as an Energy Manager (CEM) from the Association of Energy Engineers in 2009. He is the V.P. of sales at Wisconsin Oven Corp.

Related Content

Oven Door Technology Improves Energy Efficiency

The RollSeal Door brings a compact, energy efficient and safe design to batch and conveyor style thermal processing units.

Read More5 Maintenance Tips for Gas Catalytic IR Ovens

Basic and periodic preventive maintenance is essential for avoiding oven downtime.

Read MoreSpecialty Oven’s Hot Benefits and Other Questions Answered

Learn about the advantages of gas catalytic infrared pre-gel ovens in this article, including how they are energy efficient and can save users time and money when integrated into their existing systems.

Read More‘Warming Up’ to the Truth about Ovens for Surface Treatment

Understanding the different types of oven heat technology for surface finishing, including how they work, and their advantages and disadvantages, can help determine the best heating solution for an application.

Read MoreRead Next

Specialty Oven’s Hot Benefits and Other Questions Answered

Learn about the advantages of gas catalytic infrared pre-gel ovens in this article, including how they are energy efficient and can save users time and money when integrated into their existing systems.

Read MorePreventative Maintenance for Industrial Ovens

A preventative maintenance schedule for your cure or dry-off oven can help avoid unplanned downtime and equipment failures.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More

.jpg;maxWidth=300;quality=90)