Electroplating or surface finishing processes are commonly used to provide increased wear and corrosion resistance to finished parts. Many finishers, however, are burdened by corrosion of their own equipment. Process or dip tanks hold aggressive solutions that are frequently at elevated temperatures. It is imperative these tanks withstand aggressive conditions to maximize productivity and limit production downtime. Repair or replacement of failed tanks and linings/liners drastically cuts productivity and can become a costly financial burden.

Steel tanks are known for their high temperature ratings and mechanical strength, but often cannot be used to contain plating solutions. These corrosive solutions attack steel, even stainless steel, and can lead to leaks and premature failure. The common alternatives to steel tanks include using plastics, both as liners and free-standing structures. Plastics protect the steel from corrosion and the solution from contamination. Plastics such as flexible polyvinyl chloride (PVC-P) and propylene (PP) are common alternatives to solid steel tanks. However, as temperatures climb and chemistries become more complex, these materials face challenges. Polyvinylidene fluoride (PVDF) liners have proven to be a higher temperature, more chemically resistant and robust option.

Materials of Construction

The most common materials used as process tanks include steel with a PVC-P lining or PP tanks. While displaying “good enough” chemical resistance in some applications, there are many instances where aggressive plating mixtures are challenging for PVC-P or PP. Many finishers are no longer satisfied with “good enough,” therefore demanding a higher quality, longer lasting and more trouble-free tank. While PVC-P lined steel tanks do not pose a fire risk, PP tanks have a high fire risk associated with elevated temperatures and electric immersion heaters. Polypropylene tanks are quickly combustible and difficult to extinguish. The limited service life, high cost of repair or replacement, desire for minimized unplanned downtime, and risks associated with these commonly used tank materials have led many finishers to evaluate their tank purchase decision-making process. Many have come to the conclusion that spending more upfront can greatly reduce the total cost of ownership over the lifetime of a process tank.

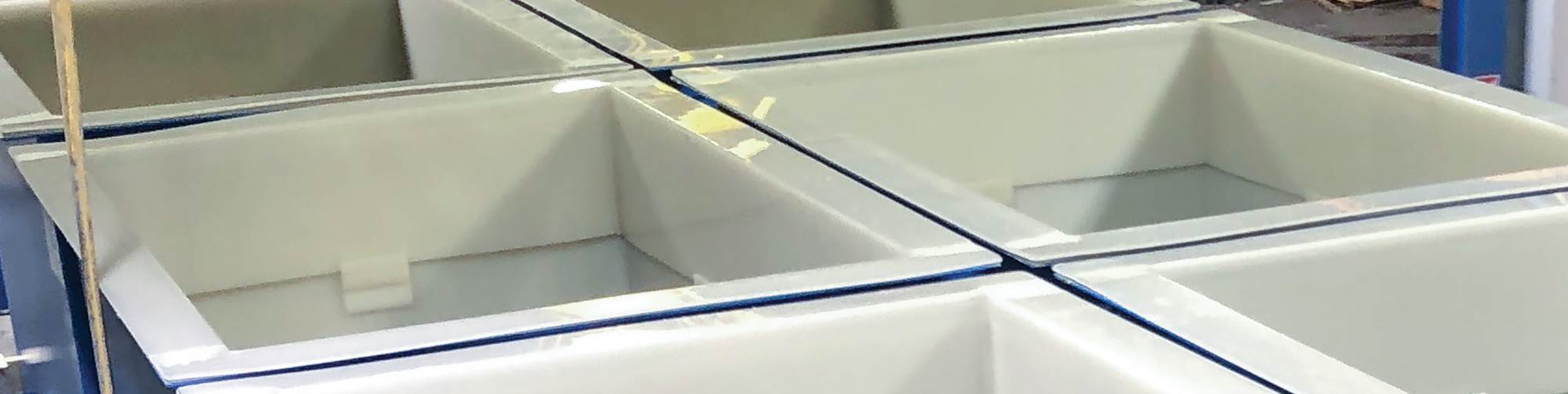

PVDF Liners Offer Upgraded Solution

For finishers who desire longer tank life, PVDF is increasingly specified as a construction material. PVDF can outperform its competition by providing longer lasting and trouble-free containment for the most aggressive plating solutions, even at elevated temperatures.

PVDF falls into a category of plastics known as fluoropolymers. In general, the fluoropolymer family is known for its robust chemical resistance, high purity, heat and temperature resistance, and good flame and smoke properties. PVDF is selected for plating tanks due to its superior permeation resistance and strong mechanical properties.

Special formulations of PVDF, known as PVDF copolymers, are the main materials used as tank linings or liners. PVDF copolymers have higher flexibility and better ductility than standard grades of PVDF. The PVDF copolymers also exhibit a wider range of chemical resistance, allowing them to be used in applications from pH <<1 to 13.5. PVDF is highly abrasion resistant, which is a key property to ensure integrity of the liner. Table 1 compares the properties of PVDF to other tank liner materials.

Table 1: Properties of Commonly Used Lining Materials

Tensile |

Impact |

Abrasion |

Continuous Temp. |

LOI |

|

|

ASTM D638/73ºF/23ºC |

ASTM D256/73ºF23ºC | (mg/1,000 cycles) CS-17 1,000g:pad | |||

| Polypropylene | 3,000 psi | 1-3 | 15-20 | 80ºC | 17 |

| Flexible PVC | 2,000 psi | No Break | 12-20 | 80ºC | 30* |

| Rubber | 1,000 psi | No Break | 70-90 | 85ºC | 20 |

| Flexible PVDF | 5,500 psi | 4-8 | 6-9 | 140ºC | 42* |

*Denotes self-extinguishing

PVDF Fabrication

As finishers become aware that there are longer lasting solutions available, PVDF is increasingly in demand. However, it is not only proper material selection that affects the life span of a process tank, but also the experience and qualifications of the fabricator constructing the tank. Qualified fabricators should have fabrication standards and procedures in place, and utilize AWS-certified plastic welding technicians. Newer plastic fabrication equipment and patented welding advancements allow tanks and liners to be constructed with only the highest quality machine welds.

Here are two case studies of the successful implementation of PVDF copolymer liners:

Solution 1 — Improving Service Life and Eliminating Contaminants: A landing gear processor was told they would have the latest and greatest in material when they elected to have their hard-chrome plating tanks lined with fiberglass overlaid with an exotic resin. In the first year, the fiberglass linings appeared to perform well, but soon thereafter the fiberglass linings began to come under attack from the chromic acid. The customer was left with failing tanks and contamination issues as the fibers from the failed lining were found in the plating bath. In 2015, 12 PVDF copolymer liners were installed in the customer’s hard-chrome plating tanks. A significant advantage of the PVDF copolymer liners is that they were installed over the failed fiberglass, eliminating the expense of new steel tanks as well as demolition and disposal of the failed ones. These PVDF liners have been in continuous operation since installation and show no sign of degradation, outperforming all alternative materials.

Solution 2 — Total Cost of Ownership/ROI: An automotive parts manufacturer had seven large hard-chrome plating tanks. Between the seven tanks, they were stripping and relining the PVC-P lining of at least one tank a year (an approximate annual expense of $55,000). With the customer’s willingness to make a larger initial investment, they purchased seven PVDF copolymer liners for their hard-chrome tanks. After installing the seven PVDF liners over flexible PVC-lined steel tanks in May 2001, the customer never required the lining supplier to rework these hard-chrome tanks. The lining supplier was advised that the customer's investment paid off in a couple of years by eliminating downtime and repair expenses. Unfortunately, this facility closed its doors in 2010 after nine years of the PVDF liners continuous service in the chrome tanks.

The materials of construction utilized in plating tanks are often the deciding factor in maximizing tank service life. Chemical resistance and temperature resistance, as well as good anti-flammability properties, are key properties to consider. PVDF liners have a proven history with delivering end users longer lasting, lower maintenance plating tanks.

Tyler Goad is operations manager at Goad Company. Gary Dennis is sales and market manager and Averie Palovcak is an applications engineer at Arkema Inc. Visit goadco.com and arkema.com.

Related Content

Prevent Plating Problems with Critical Inspections

Tanks and their contents should be regularly inspected visually and analytically. When a quality issue arises, it is important to quickly pinpoint where the main problem is by checking which parameter is out of line.

Read MoreCalculating the Cost of Powder Coating

How can you calculate the cost of powder coating a component if you only know its surface area? Powder coating expert Rodger Talbert has the answer.

Read MoreCuring Oven Basics

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...

Read MoreHow to Address Declining Powder Coating Coverage Over Time

Fine particles from reclaim could be to blame for powder coating problems that emerge over time. Avoid problems by keeping hooks clean, maintaining guns and using reclaim powder quickly to avoid accumulation of fines.

Read MoreRead Next

A ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More