Mechanical Finishing Clinic: Recoverable Blasting Media

Q. We blast with a No. 9 glass bead media in our blast cabinets, but are interested in what our hourly media cost would be and how cost compares to other medias?

Q. We blast with a No. 9 glass bead media in our blast cabinets, but are interested in what our hourly media cost would be and how cost compares to other medias?

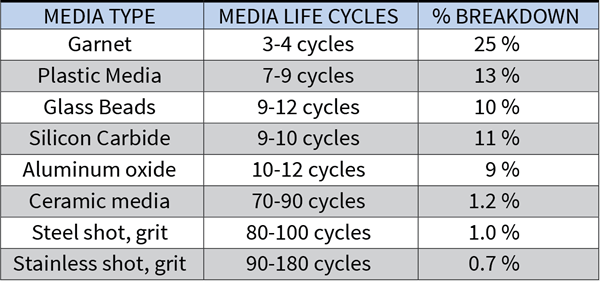

A. Here are estimates of recoverable media life cycles and cost per hour. There are many medias, but these are the most popular types for blasting in recoverable media systems.

Note: Material blasted, blast pressure (psi), blast angle and nozzle distance from the part affect media life. Nozzle size will determine the media’s hourly delivery rates.

Media Cost Per Hour: Hourly media delivery in lbs. × % breakdown ×cost per pound = Media cost per hour.

Media Cost Per Part: Hourly media delivery × % breakdown × cost per pound × part blast cycle time (percent of hour) = Media cost to blast a part.

Other factors in total blasting cost include: Air compressors or wheel motors usage, labor, blast system cost, and media disposal fee. When blasting heavy metals, a highly recyclable media is recommended to minimize disposal cost.

Originally published in the November 2016 issue.

Related Content

-

Blast Nozzle Features Enhanced Noise Reduction

Kennametal adds noise-reducing Blast Ninja to portfolio of abrasive blast nozzles.

-

Robot-Ready Grinding Systems for High-Speed Production

Advanced rotary surface grinders now come “robot-ready” to facilitate integration with third party robotic arms and fully automate the process from loading to unloading.

-

Hubbard-Hall Technical Team Adds Senior Chemist to Staff

David Keller is joining the Hubbard-Hall technical team as a senior chemist.