VIDEO: Mercedes-Benz Picks Ecopaint RoDip for New SC Plant

Rotating vehicles up to 26 feet long through an immersion bath is something that has never happened before, says Dürr Group, one of the world's leading mechanical and plant engineering firms with automation expertise.

Rotating vehicles up to 26 feet long through an immersion bath is something that has never happened before, says Dürr Group, one of the world's leading mechanical and plant engineering firms with automation expertise.

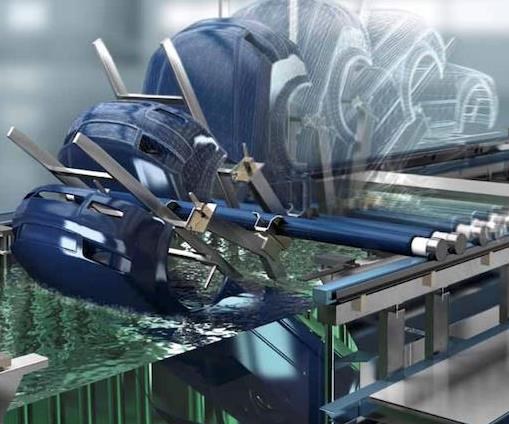

But the Ecopaint RoDip rotational dip process is now being used for the first time for vehicles of this size. Dürr will be installing this technology in the new Mercedes-Benz Vans factory in North Charleston, South Carolina. It will form part of a complete paint shop being built by Dürr on behalf of Mercedes-Benz Vans. Completion is expected by 2020.

Even very large car bodies — such as those of transporters and vans — can rotate around their own axis with a rotational movement of 360°. When planning the plant in North Charleston, Dürr conducted extensive tests in its technical center. This included testing ways of using the RoDip rotational dip process for painting car bodies larger than had ever been immersed before. The result? RoDip guarantees high-quality corrosion protection as a basis for further surface coating, even for large vehicles.

The system will transport the closed car bodies of the next generation of the Mercedes-Benz Sprinter through pretreatment and cathodic electrocoating. Each of the freely programmable transport units has a separate drive for rotation in addition to the conveying drive.

The individually programmable transport units enable optimized dip curves for the respective car body. The end result is better coating quality and increased energy efficiency. The rotational process means that smaller bath volumes are possible; these require less volume of chemicals and fresh water while reducing the energy consumption and volume of wastewater.

Mercedes-Benz Vans announced its plans to extend its existing assembly location for vans and build a new factory for the production of the Mercedes-Benz Sprinter in 2015. Production is due to start before the end of the decade. Until then, Sprinters for the U.S. market will be manufactured in Germany. Due to high import duties, however, they will be partially disassembled in a complex process and reassembled in the plant in North Charleston.

According to Daimler, this additional step puts Mercedes-Benz Vans at a clear competitive disadvantage in the US market. The new factory and vehicles “made in USA” will enable the division to service the growing demand from North American customers much more economically in the future, and significantly reduce the delivery times in the market. The division is investing approximately $500 million in the construction of the factory. Mercedes-Benz Vans is the only manufacturer in the large transporter segment that is still manufacturing in Germany.

Get more information HERE.

Related Content

-

TTX’s Automated Conveyor Carrier System Offers Wireless, Flexible Operation

ACC system designed for reliable, consistent point-to-point movement of everything from small to heavy parts.

-

Professional Plating Expands Zinc, Ecoat Offerings

Ever expanding, Professional Plating of Brillion, Wisc., has announced two capital investments: a second zinc line and an upgrade of its ecoat capabilities.

-

Top Shop Leader Focuses on Its People as Key to Success

Twin Cities job shop, Avtec, was named a Top Shop for the third time in 2022, due in no small part to its commitment not only to the work it produces but to those who produce it — its employees.