Mercedes-Benz to use novel cylinder coating technology

Technology decreases 4.3 kg of engine weight and reduces fuel consumption by 3%

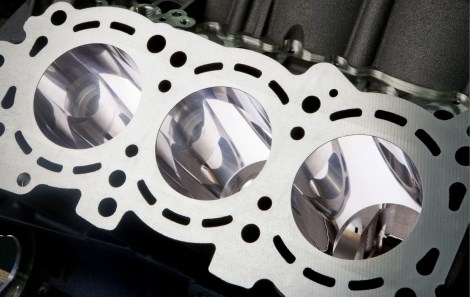

Mercedes-Benz says it will use a new cylinder coating technology “Nanoslide” coating technology in its V6 diesel engines, a technology it says decreases 4.3 kg of engine weight and reduces the fuel consumption by 3%.

Nanoslide is an innovative twin-wire arc spraying technique which the company has been utilizing successfully in its 6.3-L AMG engines.

The Nanoslide technology employs the twin-wire arc spraying technique to melt and spray carbon/iron wires onto the weightless aluminium crankcase’s cylinder surfaces utilizing a gasflow to produce an ultra-fine to nano-crystalline iron coating. A unique honing process is then employed on the Nanoslide coating to give an exceptional mirror-like finish, which now has a thickness of merely 0.1-0.15 mm.

The honing process also creates pores in the material to hold oil, which in turn offers maximum lubrication to the piston assembly. The smoother coating with fine pores decreases wear and friction between the cylinder wall and the piston assembly. Lower emissions, lower fuel consumption and lower engine weight are the other benefits of the technology.

Mercedes-Benz released a 6.3 litre V8 in July 2005, the first production engine in the world with cylinder walls featuring a nano-crystalline iron coating. Since 2006, the twin-wire arc sprayed coating has become a critical component of the company’s 6.3-L AMG engines. The technology decreases 4.3 kg of engine weight when compared to previous engines, which in turn reduces the fuel consumption by 3%. The technology has several novel ideas and inventions and is protected by more than 40 patents and over 90 patent families.

Related Content

-

Innovation in Plating on Plastic

Plating on advanced plastics solution offers improved adhesion, temperature resistance and cost savings.

-

Trivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

-

3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.