Ag-Nano System has developed a new method of electroplating based on golden silver nanoparticles — a potential replacement for gold plating used in electrical circuits.

Photo Credit: Ag-Nano System LLC

All that glitters may not necessarily be gold — at least when it comes to gold plating. Ag-Nano System LLC (Bloomfield Hills, MI) is a start-up dedicated to a new method of electroplating based on golden silver nanoparticles that are said to exhibit the properties and appearance of gold.

The process was developed and patented by Ag-Nano System founder and CEO Margaret E. Parker. Parker has 25 years of experience as an engineer in the industry and is the inventor of Turbo Titanium Technology for Broad Applications. She built her career working for GM, Chrysler, Solar Turbines, Cobham Electronics and her previous start-up, Crista Chemical Company LLC (3C).

The idea behind Ag-Nano System is as a potential replacement gold plating, which is commonly used in electrical circuits. For example, while the contacts in circuit breakers, switches and relays found in appliances and electrical devices are made of various metals such as nickel, copper, cadmium or their alloys, they are often plated in a thin layer of gold to enhance the conductivity of the circuit.

The problem with gold, of course, is that it is expensive — currently around $1800 per troy ounce. According to Parker, to create a bath for gold plating you use one ounce of gold per gallon, so you can spend $50,000 – $100,000 just to make the bath. The few companies that produce alternatives to gold coating mostly use palladium and platinum alloys which are also costly and cannot match the properties of gold.

“Until now there was nothing to my knowledge that could meet the ASTM B-488 standard, which is standard for gold plating,” Parker says.

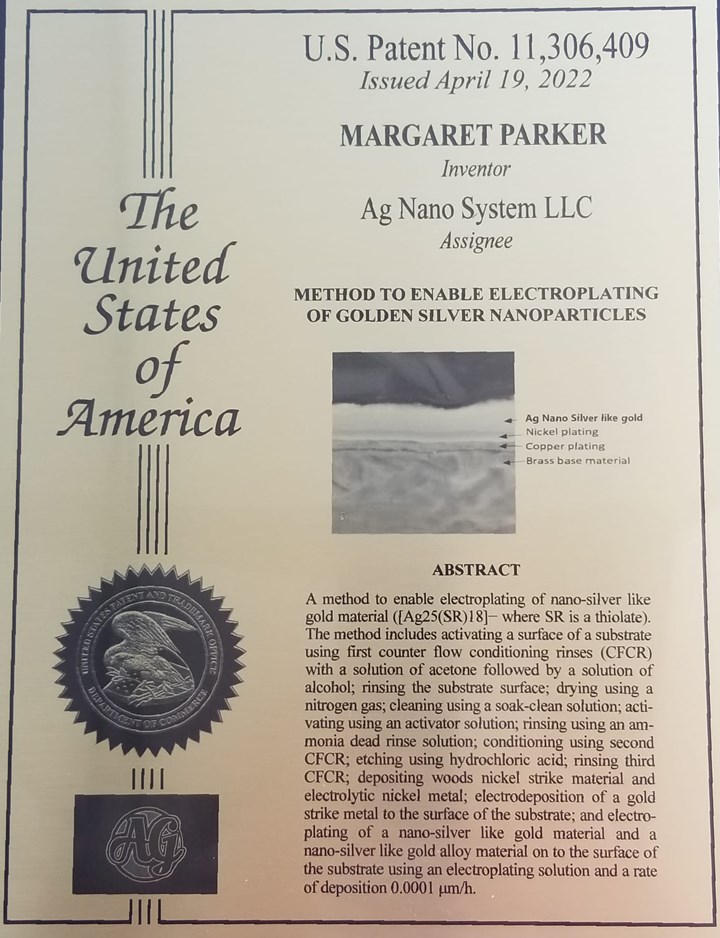

Parker shows off U.S. Patent for AG Nano.

Photo Credit: Ag-Nano System LLC

Parker says Ag-Nano System’s nano-silver coating can acquire the properties and appearance of gold coating and that the silver electroplating process is at least 2–3 times less expensive than a gold electroplating process. The method meets traditional gold plating standards MIL-G-45204, DTL-45204 and ASTM B-488. In addition, the technology is eco-friendly and does not need a special treatment of cyanide chemicals.

Parker says there is a great deal of potential for Ag-Nano System’s coating based on the growth in applications that use gold plating.

“Growth is huge right now in the electronics industry, especially with applications in automotive and aerospace — everywhere you see electronics and 5g sensors, there is gold plating,” she says.

Related Content

-

Innovation in Plating on Plastic

Plating on advanced plastics solution offers improved adhesion, temperature resistance and cost savings.

-

Advantages to Pumped Eductor Agitation

Not all agitation methods are created equally. Pumped agitation with eductor nozzles can improve process tanks and quickly show a reduction in operating costs while keeping staff safe, following environmental legislation and preventing pollution.

-

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.