NASF/AESF Foundation Research Project #121: Development of a Sustainability Metrics System and a Technical Solution Method for Sustainable Metal Finishing: 1st Quarterly Report

This report (1) introduces the new project and (2) covers the first quarter of project work (April-June 2020) on this project at Wayne State University in Detroit. The objective is to help metal finishing plants to conduct a self-managed sustainability assessment and identify technical solutions for sustainability performance improvement. The reader is invited to contact Dr. Huang in identifying plating shops willing to participate in this program.

1st Quarterly Report

April-June 2020

AESF Research Project #R-121

by

Yinlun Huang*

Department of Chemical Engineering and Materials Science

Wayne State University

Detroit, Michigan, USA

Editor’s Note: This NASF-AESF Foundation research project report (1) introduces the project and (2) covers the first quarter of project work (April-June 2020) at Wayne State University in Detroit. The reader is invited to contact Dr. Huang in identifying plating shops willing to participate in this program. A printable PDF version of this report is available by clicking HERE.

Part 1 - Introduction to the Project Work

1. Introduction and Significance to NASF

The surface finishing industry is critical to many manufacturing industries, such as automotive, aerospace, electronics, defense, and other OEMs, as the finish on a surface can have a huge effect on the performance and durability of parts used by those industries. This industry however, has faced various challenges. According to a recent benchmarking survey on a large number of electroplating facilities (Products Finishing, April 2018), about 80% of them ran at a low profit margin (6% in 2016; 5% in 2017). This industry has been also highly regulated by US EPA due to the daily use of a variety of toxic/hazardous chemicals and the generation of huge amounts of waste in various forms, which are potentially very harmful to the environment, human health and communities. All of these are industry sustainability problems in its development.

It has become widely recognized in many industries, especially large corporations, that sustainability is a key driver of innovation, and it is shown evidently that a large number of companies that make sustainability as a goal are achieving a significant competitive advantage. Unfortunately, the surface finishing industry is far behind others in response to the industrial sustainable development (SD) needs. Most surface finishing facilities are small (500 employees or less in each) and lack a deep understanding of SD. They have little knowledge, experience and funds to identify, analyze and improve sustainability in their facilities. They also worry about the possibility of effecting profitability if pursuing sustainability. At the national level, “Advancing a Sustainable Future” has been advocated by NASF. During the SUR/FIN conferences in recent years, more and more industrial practitioners have presented their views, methods and techniques, which covered various aspects of sustainability. However, the industry lacks even the first version of a sustainability metrics system for the facilities to conduct basic sustainability assessments of processes, chemicals, products and plants. At present, there exists no method, guideline or tool to assist plants in developing strategic goals and plans for sustainability performance improvement, while ensuring profitability. The industry needs all of these urgently.

To meet the industrial need, this research project was proposed with the following set of goals:

- Create a surface-finishing-specific sustainability metrics system, which will contain sets of indicators to measure economic, environmental and social sustainability,

- Develop a general and effective method for systematically assessing the sustainability performance of any electroplating plant that may have multiple plating lines as well as the capacities of technologies for sustainability performance improvement and

- Develop a sustainability-oriented decision-analysis/decision-making method that can be used to analyze sustainability assessment results, identify and rank weaknesses in the economic, environmental and social categories, and then generate optimal technical recommendations for sustainability performance improvement and profitability assurance in plants.

- Introduce the sustainability metrics system and methods for sustainability assessment and strategy analysis to the industry.

This will help metal finishing facilities to conduct a self-managed sustainability assessment as well as identify technical solutions for sustainability performance improvement.

Part 2 - 1st Quarterly Report (April-June 2020)

The original research plan was to hire a graduate student to conduct the proposed research with applications under the guidance of the Principal Investigator (PI), Dr. Huang. However, due to the COVID-19 pandemic crisis, Michigan Governor issued a stay-at-home order on March 23, 2020. Since then, Wayne State University has been closed. We were thus unable to hire a student for the project during the summer. Therefore, in this reporting period, no student is involved in the project. Depending on the situation over the Summer, it is hoped that a suitable student can be identified for the start of the Fall semester. What follows then, is the progress made by the PI during this period.

Addition of key components for the development of sustainability metrics system

The metrics system is being developed by resorting to sustainability science and engineering fundamentals. Sustainability is a triple-bottom-line-balance-based concept and practice; it emphasizes a long-lasting economic, environmental and social development. Thus, an effective sustainability metrics system must consist of indicators in all three categories, which should be readily used over time so that the sustainability performance of an industrial system can be monitored and solutions for performance improvement can be identified and implemented.

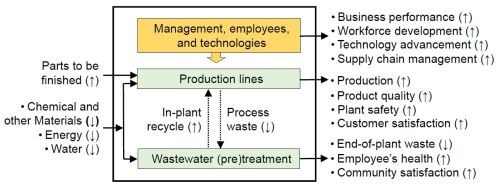

For the metal finishing industry to be sustainable, each plant should be evaluated to identify its current and future states of sustainability. This requires identification of the factors that are closely related to the plant’s sustainability performance, including production lines and wastewater handling. Since the inception of this project, the plan was modified to include a critical set of components, as shown in Fig. 1. The three components, namely Management, Employees and Technologies, are plotted in the orange-colored box of the figure. This addition allows us to include explicitly the assessment of the business performance, workforce development, technology advancement and supply chain management. This addition will require the development of sustainability indicators to evaluate more broadly the economic, environmental and social performance.

Figure 1 - Sketch of a metal finishing plant with major sustainability concerns.

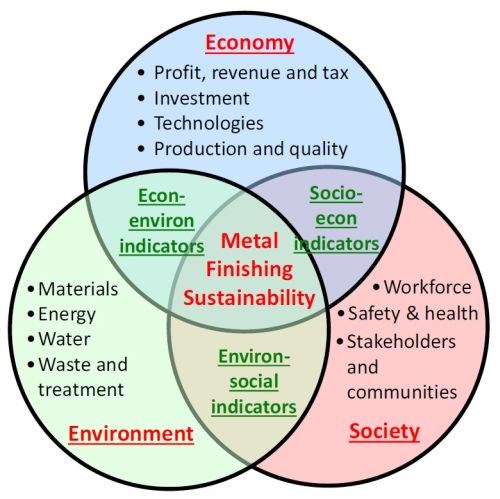

Determination of sustainability metrics system categories

Based on the analysis of the factors that are closely related to the plant’s sustainability performance that are shown in Fig. 1, we have grouped them into three sustainability categories, i.e., the economic, environmental and social categories, which are shown in Fig. 2. This categorization is significant as it clearly indicates a need for the development of various sustainability indicators, including economic-environmental indicators, environmental-social indicators, and social-economic indicators. For instance, the amount of solvents consumed in cleaning systems (a type of material) not only has a cost issue (an economic issue, related to profit, cleaning quality, etc.), but also is related to water use in the rinsing systems as well as the wastewater treatment system (an environmental issue). Thus, one or more sustainability indicators would be needed in the category of “economic-environmental indicators,” Moreover, the emission of solvents in production lines will be directly related to process safety and operator health (a social issue). This requires the development a few environmental-social indicators. On the other hand, production and product quality are not only related to the profit in the economy category, but also directly relevant to the satisfaction of stakeholders, including employees, customers, suppliers and investors, in the society category. Thus, a few social-economic indicators should be developed.

Figure 2 - Triple-bottom-line-based sustainability and its elements.

Development of initial sets of sustainability indicators

The classification of the sustainability metrics system categories depicted in Fig. 2 provides a guideline for the development of sustainability indicators. In the following, the initial sets of 52 indicators in the three categories (i.e., economic, environmental and social sustainability) are listed below.

Economic sustainability indicator set

This set contains 20 indicators in four sub-categories:

Sub-category E-1: Profit, Value and Tax

E-1-1 Value added ($/yr)

E-1-2 Value added per direct employee ($/yr)

E-1-3 Net profit margin (%/$)

E-1-4 Net profit per direct employee ($/yr)

E-1-5 Tax paid as percent of NIBT (%)

E-1-6 Return on average capital employed (%/yr)

Sub-category E-2: Investments

E-2-1 Percentage increase in capital employed (%/yr)

E-2-2 Percentage of new employees (%/yr)

E-2-3 Percentage of training vs payroll expense (%)

E-2-4 Investment for employee’s education/training

E-2-5 Investment on new technology ($/yr)

Sub-category E-3: Technology Advancement

E-3-1 Production increment percentage per dollar investment on new technology (%/$-new tech)

E-3-2 Production increment percentage per dollar investment on technology improvement (%/$-existing tech)

E-3-3 Product quality improvement percentage per dollar investment on new technology (%/$-new tech)

E-3-4 Product quality improvement percentage per dollar investment on technology improvement (%/$-existing tech)

E-3-5 Waste reduction percentage per dollar investment on new technology (%/$-new tech)

E-3-6 Waste reduction percentage per dollar investment on technology improvement (%/$-existing tech)

Sub-category E-4: Production and Product Quality

E-4-1 Percentage of product delivered on time (%)

E-4-2 Product defect rate during production (%)

E-4-3 Product return rate after shipment (%)

Environmental Sustainability Indicator Set

This set contains 18 indicators in three sub- categories:

Sub-category V-1: Materials (excluding fuel and water)

V-1-1 Chemical use in production per value added (lb./$)

V-1-2 Chemical use in production per dollar of product sales (lb./$)

V-1-3 Chemical use in waste treatment per value added (lb./$)

V-1-4 Plating solution use per value added (lb./$)

V-1-5 Plating use per dollar of product sales (lb./$)

V-1-6 Other material use per dollar of product sales (lb./$)

Sub-category V-2: Water

V-2-1 Fresh water use in production per dollar of product sales (lb./$)

V-2-2 Used water reused in production before treatment (%)

V-2-3 Fraction of water recycled within plant (%)

Sub-category V-3: Energy

V-3-1 Electricity use per dollar of sales (kW/$)

V-3-2 Natural gas and oil use per dollar of sales (MMBtu/$)

V-3-3 Clean energy use among all energy (%)

V-3-4 Non-production energy among all energy consumption (%)

Sub-category V-4: Waste Generation and Effluents

V-3-1 Spent solutions per value added (lb/$)

V-3-2 Wastewater generated in production per value added (lb./$)

V-3-3 Wastewater treatment sludge per value added (lb./$)

V-3-4 Hazardous waste generated per value added (lb./$)

V-3-5 Non-hazardous waste generated per value added (lb./$)

Social Sustainability Indicator Set

This set contains 14 indicators in three sub- categories:

Sub-category L-1: Workplace

L-1-1 Benefits as percentage of payroll expense (%)

L-1-2 Work related re-education and/or training (%)

L-1-3 Employee turnover (resigned + redundant / employed) (%)

L-1-4 Promotion rate (promotions / employed) (%)

L-1-5 Working hours lost as percent of total hours worked (%)

Sub-category L-2: Safety and Health

L-2-1 Number of process safety review ( /yr)

L-2-2 Number of accidents in workplace ( /yr)

L-2-3 Chemical leakage in plant ( /yr)

L-2-4 Human health burden (carcinogenic) per value added ( /$)

Sub-category L-3: Society

L-3-1 Number of stakeholder meetings ( /yr)

L-3-2 Indirect community benefit ($/yr)

L-3-3 Number of complaints from local community ( /yr)

L-3-4 Number of complaints from customers ( /yr)

L-3-5 Number of legal actions per value added ( /yr)

Refinement of the Initial Sustainability Metrics

As shown in Fig. 2, there are three sustainability categories, i.e., the economic, environmental and social categories. In each category, there are three or four subcategories. We have studied a large number of sustainability metrics systems for the chemical and manufacturing industries in the U.S. and Europe. Based on research and industrial experience in the metal finishing industry, a basic strategy for the development of the above initial sustainability metrics system is its inclusiveness, i.e., to include as many sustainability indicators as possible for now. Nonetheless, it is still possible that some additional sustainability indicators could be added, and some indicators listed above may be modified.

The more the number of indicators, the more comprehensive the sustainability performance assessment could be. However, this would require more information from users. Collection of information and data from plants could be costly and time consuming. In many cases, the collected information and data are incomplete, imprecise and uncertain. This could make the sustainability assessment task extremely challenging.

The original plan for the refinement of the initial sustainability metrics system was to present a paper, titled “Development of a Sustainability Metrics System for the Assessment and Improvement of Metal Finishing Facilities’ Sustainability Performance”, at the SUR/FIN 2020 Conference in Atlanta, enabling the collection of feedback from the audience, and identifying a number of platers who might be interested in discussing more about sustainability metrics and potentially for test use. Nevertheless, the conference was cancelled due to the impact of COVID-19 developments, and thus the original plan could not take place.

Outreach effort

The Principal Investigator (PI) contacted Christian Richter and Jeff Hannapel of NASF/AESF Foundation Headquarters on April 29, seeking a permission to access the P2 survey data from the project with EPA Region 5 and NCMS; the PI obtained the survey data immediately. The data set contains the survey information from 29 plating shops. This is possibly the most recent data available in the electroplating industry, although the data sets are insufficient to draw any statistical conclusions for the metal finishing industry. However, the data set is still very useful, and it will be analyzed in the 2nd project year, as scheduled in the original proposal.

The PI also contacted Robert Burger, President of KC Jones Plating in Hazel Park, MI on June 14, which was a delayed communication due to the COVID-19 pandemic impact. The AESF-funded project was briefly discussed and it was decided to discuss it further after the plant’s business returns to normal, hopefully in the Fall.

Plan for the 2nd quarter (7/1/20 – 9/30/20)

Refinement of the initial sustainability metrics system will be a major task. As stated early in this report, student recruitment is a major challenge due to the pandemic situations. It is very likely that there will still be no student involved in the 2nd quarter of the project.

The current plan is as follows:

- Review the initial sustainability metrics system, and divide the 52 sustainability indicators into two sets:

Set A - an indicator set that contains a minimum number of indicators definitely needed for conducting a meaningful assessment of sustainability in plants, although the scope would be limited.

Set B - an indicator set that contains the remaining indictors that can be used for more comprehensive sustainability assessment.

- Develop a complete list of parameters that are necessary for evaluating the values of the indicators in Set A. The list will be also associated with a general guideline for data/information collection, such as data type and amount, and data collection duration. An indicator parameterization map will be also developed, which will clearly show how plant variables and parameters should be used for evaluating each sustainability indicators in Set A.

- Contact the Research Board to seek advice on the identification of metal finishing companies who might be interested in reviewing the initial sustainability metrics systems and providing feedback. We would then contact those plants.

About the author

Dr. Yinlun Huang is a Professor at Wayne State University (Detroit, Michigan) in the Department of Chemical Engineering and Materials Science. He is Director of the Laboratory for Multiscale Complex Systems Science and Engineering, the Chemical Engineering and Materials Science Graduate Programs and the Sustainable Engineering Graduate Certificate Program, in the College of Engineering. He has ably mentored many students, both Graduate and Undergraduate, during his work at Wayne State.

He holds a Bachelor of Science degree (1982) from Zhejiang University (Hangzhou, Zhejiang Province, China), and M.S. (1988) and Ph.D. (1992) degrees from Kansas State University (Manhattan, Kansas). He then joined the University of Texas at Austin as a postdoctoral research fellow (1992). In 1993, he joined Wayne State University as Assistant Professor, eventually becoming Full Professor from 2002 to the present. He has authored or co-authored over 220 publications since 1988, a number of which have been the recipient of awards over the years.

His research interests include multiscale complex systems; sustainability science; integrated material, product and process design and manufacturing; computational multifunctional nano-material development and manufacturing; and multiscale information processing and computational methods.

He has served in many editorial capacities on various journals, as Co-Editor of the ASTM Journal of Smart and Sustainable Manufacturing Systems, Associate Editor of Frontiers in Chemical Engineering, Guest Editor or member of the Editorial Board, including the ACS Sustainable Chemistry and Engineering, Chinese Journal of Chemical Engineering, the Journal of Clean Technologies and Environmental Policy, the Journal of Nano Energy and Power Research. In particular, he was a member of the Editorial Board of the AESF-published Journal of Applied Surface Finishing during the years of its publication (2006-2008).

He has served the AESF and NASF in many capacities, including the AESF Board of Directors during the transition period from the AESF to the NASF. He served as Board of Directors liaison to the AESF Research Board and was a member of the AESF Research and Publications Boards, as well as the Pollution Prevention Committee. With the NASF, he served as a member of the Board of Trustees of the AESF Foundation. He has also been active in the American Chemical Society (ACS) and the American Institute of Chemical Engineers (AIChE).

He was the 2013 Recipient of the NASF William Blum Scientific Achievement Award and delivered the William Blum Memorial Lecture at SUR/FIN 2014 in Cleveland, Ohio. He was elected AIChE Fellow in 2014 and NASF Fellow in 2017. He was a Fulbright Scholar in 2008 and has been a Visiting Professor at many institutions, including the Technical University of Berlin and Tsinghua University in China. His many other awards include the AIChE Research Excellence in Sustainable Engineering Award (2010), AIChE Sustainable Engineering Education Award (2016), the Michigan Green Chemistry Governor’s Award (2009) and several awards for teaching and graduate mentoring from Wayne State University, and Wayne State University’s Charles H. Gershenson Distinguished Faculty Fellow Award.

* Dr. Yinlun Huang, Professor

Dept. of Chemical Engineering and Materials Science

Wayne State University

Detroit, MI 48202

Office: (313) 577-3771

E-mail: yhuang@wayne.edu

Related Content

Hexavalent-Chromium-Free Aluminum Sacrificial Paint Validation

Hexavalent chromium is a known carcinogen, repro-toxin and mutagen. Its elimination is of high importance to the aerospace industry, which has struggled to find high performing alternatives. Legacy aluminum sacrificial paints have traditionally utilized hexavalent chromium to prevent corrosion and coatings which are equal to or better than have been difficult. This second of two papers discusses the hexavalent-chromium-free process from the user point-of-view in terms of the process validation work by Rolls Royce Corporation.

Read MoreHighlights from SUR/FIN 2023

Products Finishing offers a recap of some of the topics that were top of mind at the SUR/FIN 2023 finishing industry trade show.

Read MoreSUR/FIN 2023 Registration Is Now Open

The National Association for Surface Finishing SUR/FIN 2023 surface finishing industry trade show will take place June 6-8, 2023 in Cleveland, Ohio.

Read MoreNASF, AESF Scholarship Program Accepting Applications

The deadline for applications is Feb. 26, 2023.

Read MoreRead Next

Episode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More