PaintExpo at the Karlsruhe Exhibition Centre in Germany will provide a platform for exhibitors to present new technologies and solutions covering the entire process sequence for liquid and powder coating.

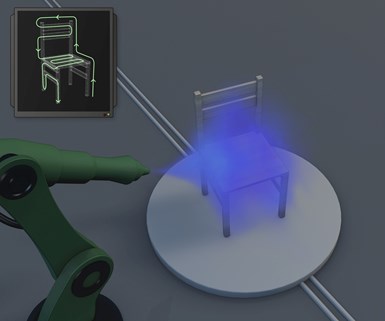

Automated painting with robots is one of the major trends in industrial painting technology. Photo courtesy of GEMA.

Compact painting cells with robots are a cost-effective way to get started with robot-based painting. Image courtesy of Reiter Oberflächentechn

The event is April 21-24, and presents some of the most up-to-date and comprehensive offerings for industrial coating technology as well as individual solutions.

Selfpaint is a self-programming robot painting cell that permits fully automated, cost-effective painting of very small manufacturing lots and single parts. Image courtesy of Fraunhofer IPA.

Exhibitors will highlight innovations, technologies, processes and services for designing, running and optimizing processes in order to meet the great demands for quality and flexibility, as well as material, energy and cost efficiency for the painting and coating of components made of metals, plastics, wood, wooden materials, glass, material combinations and more. This begins with parts pretreatment and includes everything from systems and application technology, conveyor systems and drying to quality assurance and packaging of the coated products.

A new development permits zero overspray painting, which makes simple multicolor painting possible without masking or intermediate drying. Image courtesy of Dürr.

There will also be a focus on new and further developed solutions for all types of coating processes, including ultra-high-solid systems, chrome replacement coatings, gel coats and systems which provide coated surfaces with special functional and/or decorative properties, improved corrosion protection and reduced consumption of materials and energy.

Simulation and automation of the coating process will also be featured. In the field of job-shop coating, Industry 4.0 is also gaining relevance with the digital integration of the coating process into production.

Application efficiency for manual and automated liquid painting can be significantly increased with the help of new electrostatic spray guns. Image courtesy of Wagner Group.

The exhibition covers:

- Systems and equipment for liquid painting, powder coating and coil coating

- Application systems and spray guns

- Wet paints and powder coatings

- Automation and conveyor technology

- Compressed air technology

- Cleaning and pretreatment

- Drying and curing

- Environmental technology, air supply and exhaust air purification, water treatment, recycling and disposal

- Accessories (for example, covering materials and systems, hangers, filters, pumps)

- Measuring and test technology, quality assurance

- Paint stripping

- Job shop coatings

- Packaging

- Services

- Training and vocational education

- Research

- Technical literature

Visit www.paintexpo.de

Related Content

-

Surface Prep Solution for Rusted Rebar in Concrete

Julie Holmquist of Cortec Corporation discusses passivating corrosion on rebar and other reinforcing metals.

-

Intumescent Coating Provides Up to 3 Hours of Fire Protection

PPG Steelguard 951 coating is designed to provide protection against fire and corrosion.

-

Zinc Phosphate: Questions and Answers

Our experts share specific questions about zinc phosphate and pretreatment