Parts Cleaning Expo Visitors Get Look at What’s Ahead

Parts Cleaning Expo attendees review the 2017 trade show and technical conference and look ahead to PCx 2019 in Cleveland, Ohio.

Seacole Specialty Chemical’s Paula Crawford-Anderson wishes the biennial Parts Cleaning Expo held in April had been around when she first started in the manufacturing industry.

“The classes were the right blend of general information and specific topics tailored to the different groups of people in attendance, such as equipment OEMs, end users of that equipment and vendors to the industry,” says Crawford-Anderson, Seacole’s business development manager. “It was some of the best trade show-related seminars I’ve attended.”

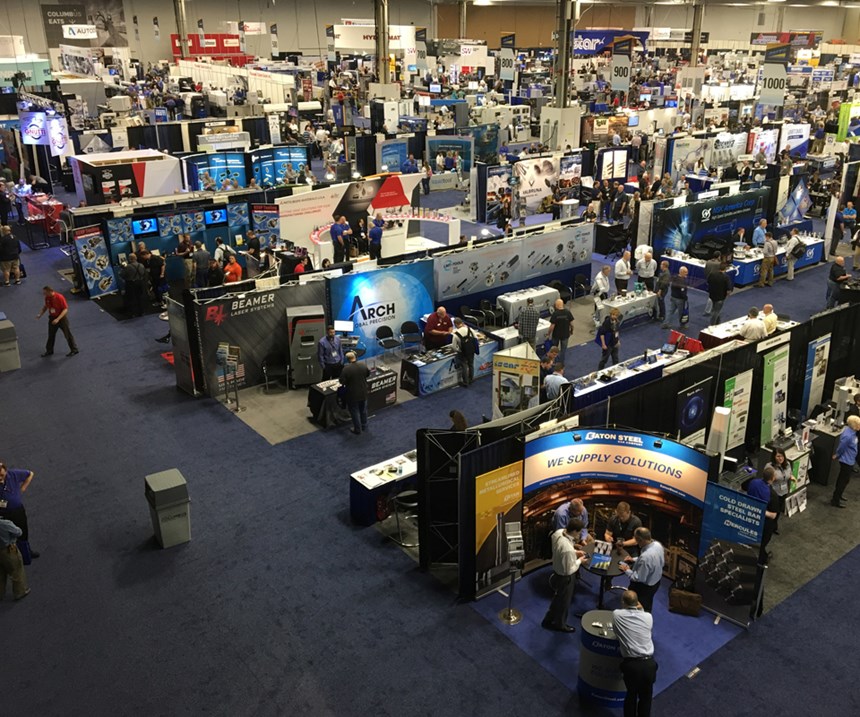

The Parts Cleaning Expo (PCx) 2017, held in Columbus, Ohio, featured a “who’s who” lineup of industry speakers at the technical conference, which was hosted in conjunction with the Precision Machining Technology Show. The show was presented by the Precision Machined Products Association (PMPA), and co-hosted by Production Machining, Products Finishing and Modern Machine Shop.

“It was my first time attending the show, and I found it to be well organized,” she says. “The information I got before the show let me decide what I wanted to see, and helped me find it quickly during the show.”

Marcia Snyder, technical services and key account manager for DeForest Enterprises, says she enjoyed visiting the Parts Cleaning Pavilion, where booths of companies offering cleaning solutions were in the same area on the show floor.

“This made it easy to see all the suppliers during breaks without having to run around the entire show floor,” she says.

The goal of the PCx Pavilion was to give attendees the opportunity to see the latest advances in cleaning equipment, chemicals and services, alongside machine tool builders, cutting tool companies, software vendors and more under one roof.

Mark Crosby, clean room supervisor at Kurt J. Lesker Co., has attended several PCx shows and rated 2017 as the best he’s attended.

“This year, I feel, was by far the best experience I have had,” Crosby says. “I spent a lot of time on the floor making contacts and seeing what’s out there to take our current process to the next level.”

He also enjoyed attending the two-day technical sessions.

“The sessions I attended were very well put together and very educational,” Crosby says. “And it was great to see individuals from all perspectives of the process were involved and passionate about the cleaning process. It’s always great to see and hear that there others out there with the same concerns and commitment to precision cleaning.”

Walter Hutter from THK Rhythm in Tillsonburg, Ontario, Canada, says the 2017 show was “more focused” than past shows he has attended. Hutter says one reason he attended the PCx show was because of a specific cleaning problem faced by his company, which manufactures ball joints, tie rods and various suspension arms and components for major automotive companies.

After a quench, a clean/anti-rust coating is applied during an induction hardening process, which he says leaves a sticky film on their ball studs, which then wreaks havoc on the torque requirement of the assembled joint.

“During one of the presentations, it was stated that we need to know what soil we are dealing with in order to clean it properly, but my problem is that my cleaner is my soil,” he says. “After the presentations were over, I was able to approach some of the presenters on the show floor and they were able to address my specific problem with some good suggestions. The quest for a solution to my problem continues, but the presenters welcomed continued dialogue to help solve my problem.”

Adam Abbas, a manufacturing engineer in finishing with TriMark Corp., says it was the first time he had been to PCx.

“We came looking for specific information regarding NPB1, and we got exactly what we were looking for,” he says. “Just hearing one of those presentations would have been worth the admission alone. We will be implementing a test for cleanliness after hearing Darren Williams’ session on contact angle analysis.”

Many of the attendees came to the show because of mandatory cleaning requirements placed on them by Tier 1 and Tier 2 suppliers to OEMs, says Francesco Piscani, applications specialist for the scientific solutions group, industrial microscopes and metrology at Olympus Corp. of America.

“I expect this process to continue, as European cleanliness requirements become commonplace in U.S. manufacturing,” says Piscani.

Ben Lang, supervisor of product development engineering at Acument Global Technologies, says PCx was a well-run show with plenty of exhibitors and great technical presentations.

“One common theme of the technical presentations was that cleaning and inspection processes need to be tailored to the components or systems in question,” he says. “The expo floor offered a wonderful opportunity to collaborate and build relationships with suppliers and customers alike.”

David Gotoff, product manager for Chemetall U.S., presented at the conference and says the technical talks do a good job of jumping right in and addressing some of the more challenging topics.

“The conference allowed for some counter positions to be voiced in a constructive manner,” he says. “We saw some interesting presentations on cleanliness and some novel approaches and technology for system control. I found it to be very insightful.”

Gotoff says the show floor was very active with high-quality displays that were staffed well. He says it was organized well and covered a good variety of applications that were appropriate for component manufacturers.

“What I really find unique about PCx is how it stands as a crossroads event for the solvent and aqueous cleaning markets, something very evident in the technical sessions,” he says. “It is a great forum to present the positives of both approaches—along with the negatives—and allow the visitor to make an educated decision on what should be best for their particular process.”

Greg Terrell, director of business development for Coventya, says he hadn’t attended the show in a while, but was impressed by the overall attendance both on the show floor and the technical sessions.

“The sessions I witnessed were interactive and interesting,” Terrell says. “We are not involved in the ‘critical’ cleaning market vertical, but I was still able to glean good information for our segment, as well as network with like-minded people who could benefit from our experience.”

Terrell says it was interesting to learn about the European cleanliness specifications, VDA 19 and ISO 16232, which potentially could come to the U.S. and impact applicators.

“Regulation continues to be the number one driver in our market,” he says.

Rich Edmonds, process improvement engineer and quality clinic coordinator at Ferrotherm Corp., attended PCx for the first time, and called the show “expansive.”

“Everywhere we went we found professionalism and seasoned experts more than willing to share,” he says. “It was impressive the amount of new technology on display. It took us all three days to go the entire length and width of the show. We will be back.”

The 2019 PCx show will be held April 2-4 in Cleveland, Ohio.Visit PMTS.com for additional information.

Originally published in the August 2017 issue.

Related Content

Top Reasons to Switch to a Better Cleaning Fluid

Venesia Hurtubise from MicroCare says switching to the new modern cleaning fluids will have a positive impact on your cleaning process.

Read More3-Stage Versus 5-Stage Washers

Columnist Rodger Talbert explains the difference between a five-stage washer and a three-stage washer, and how one provides better corrosion protection over the other.

Read MoreAlkaline Cleaning Guide

Gregg Sanko, Senior Chemist, Oakite Products, Inc. provides an overview of the alkaline cleaning process.

Read MoreVacuum Degreaser Cleans Up a Messy Situation

By replacing its immersion parts washer with a vacuum degreasing system, this machine shop is much more efficient, saving the company money, man hours and the health of the operators.

Read MoreRead Next

Episode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More

.jpg;maxWidth=300;quality=90)