Powder Coating Allows for Maximum Flexibility for Venerable Harley Davidson

Harley-Davidson backs up its in-your-face slogan - “It’s one thing to have people buy your product.

Harley-Davidson backs up its in-your-face slogan - “It’s one thing to have people buy your product. It’s another for them to tattoo your name on their bodies” - with a solid record of performance. It has set sales and production records for 14 consecutive years. Many factors are responsible for Harley Davidson's economic success and near-cult brand loyalty. One of the most important has been powder coating.

Until late 1994, Harley Davidson’s Milwaukee power train division used liquid paint on the engines and transmissions it manufactured. But there were problems. “One of the big reasons that steered us toward powder was stability,” explained Ken Ellis, the Senior Manufacturing Engineer.

That wasn’t all. “There were cost, performance and environmental advantages of powder as well,” Mr. Ellis said. “When we liquid painted our components, many of them had to be painted after machining, which was much more costly.”

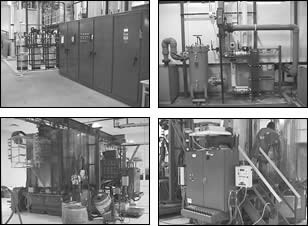

Harley-Davidson now powder coats all the components of its drive train at a powder coating facility in Milwaukee that services two manufacturing plants. The facility has a dual line conveyor system with a capacity of approximately 10,000 parts per day. For each line, there is an inverted enclosed track system. Parts pass through six stages: pretreatment washer, a dry-off oven and a cool-down chamber, then an environmental room, a cure oven and final cool-down chambers. Parts are powder coated black or silver using a combination of automatic and manual guns. According to Mr. Ellis, the plant produces parts with a wide variety of shapes and sizes.

The new plant gives Harley-Davidson the chance to increase its efficiency even more. Mr. Ellis said, “We’re looking for some line speed improvements with the new facility. Also, we are doing some technical improvements, including more automation, better layout and greater flexibility. We will have the latest technology that is out there right now.”

There is one particular technological enhancement that the company is especially proud of. “We’ve gone to automatic feed pumps to control our wash line stages, which is something we’ve been doing for a while. However, we now download that data into a statistical process control (SPC) package,” he continued. “Every fifteen minutes, we download information from our wash line, whether it be temperature, pH or concentration, into the SPC package, so at any remote location in the plant, you can watch how the wash line is performing. We get a much better picture of what is happening in our wash line at any given time. It gives us confidence in the performance of the end product.”

With the influx of data, the rate of defects has decreased dramatically, which saves the company time and money.

Outside of Milwaukee, the company uses powder coating for the clear coat on its tanks and fenders, and motorcycle frames are powder coated at plants in York, Pennsylvania, and Kansas City, Missouri.

And who knows what lies ahead? The company has begun powder coating motorcycle parts that have been traditionally chromium plated or polished, which are already winning customers in Europe.

Related Content

Products Finishing Reveals 2023 Qualifying Top Shops

Each year PF conducts its Top Shops Benchmarking Survey, offering shops a tool to better understand their overall performance in the industry. The program also recognizes shops that meet a set of criteria to qualify as Top Shops.

Read MorePowder Coating 4.0: Smarter, Faster, More Efficient and Connected

New tools reduce cost and waste, lower manufacturing footprint of powder coating operations.

Read MoreMasking Solutions Provider CFS Dramatically Expands Capabilities and Capacity

Custom Fabrication & Supplies (CFS) completed a new plant expansion packing 10 times the capacity into twice the space. It dramatically enhances the supplier’s custom capabilities to provide extremely precise and cost-effective masking solutions.

Read MoreHow to Address Declining Powder Coating Coverage Over Time

Fine particles from reclaim could be to blame for powder coating problems that emerge over time. Avoid problems by keeping hooks clean, maintaining guns and using reclaim powder quickly to avoid accumulation of fines.

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read More

.jpg;maxWidth=300;quality=90)