The Science of Watching Paint Dry

New research shows a new physical mechanism that separates particles according to their size during the drying of wet coatings.

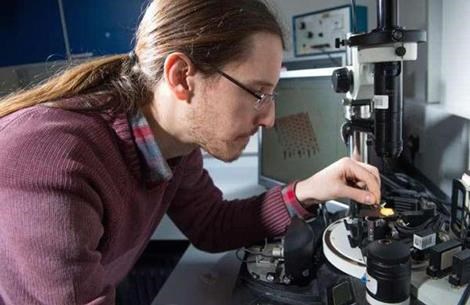

Researchers from the University of Surrey in collaboration with the Université Claude Bernard Lyon used computer simulation and material experiments to show how when coatings with different sized particles (such as paints) dry, the coating spontaneously forms two layers.

This mechanism can be used to control the properties at the top and bottom of coatings independently, which could help increase performance of coatings across industries as diverse as beauty and pharmaceuticals.

“When coatings such as paint, ink or even outer layers on tablets are made, they work by spreading a liquid containing solid particles onto a surface, and allowing the liquid to evaporate,” said Dr Andrea Fortini, of the University of Surrey and lead author. “This is nothing new, but what is exciting is that we’ve shown that during evaporation, the small particles push away the larger ones, remaining at the top surface whilst the larger are pushed to bottom. This happens naturally.”

The team is continuing to work on such research to understand how to control the width of the layer by changing the type and amount of small particles in the coating and explore their use in industrial products such as paints, inks, and adhesives

The funding for this work comes from the EU project BARRIERPLUS, which aims at the reduction of environmentally damaging volatile organic compounds in paints.

Related Content

-

Quick Turnaround is Key for Architectural Coating Shop

This California metal fabricator and coater focuses on fast turnaround and streamlining its processes with 40 years of experience in the construction industry.

-

Catalytic Gel Ovens Offer Small Operational Footprint

WolfRayet catalytic gel ovens offer small operational footprints while also providing a way to improve on existing convection curing.

-

Oven System Wins Pace Award

The EcoInCure is designed to cure complex car bodies with superior paint quality faster and more efficiently than conventional ovens.