Winona Powder Coating Announces Expansion

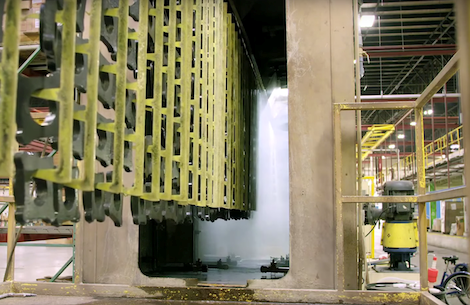

The 167,000-square-foot facility currently houses state-of-the-art powder coating lines, sand blasting, wheelabrating, and the expanded batch system.

Winona Powder Coating, one of the largest high-volume powder coaters in Northern Indiana and Southern Michigan, says it has completed the expansion of its batch line to handle products up to 32 feet long. The 167,000-square-foot facility currently houses state-of-the-art powder coating lines, sand blasting, wheelabrating and the expanded batch system.

“Since adding the batch line at Winona two years ago, customers have continually presented ever larger parts and projects for us to powder coat,” says Brian Bailey, president of Winona Powder Coating. “By doubling the length of the system, we will be able to coat oversized parts for the many industries we serve.”

Winona Powder Coating, with facilities in Elkhart and Etna Green, Indiana, is a leading supplier of powder coating services to large industrial companies throughout the Midwest. In business since 1974, Winona Powder Coating began powder coating in 1979, making it one of the first powder coating operations to open in the state of Indiana.

The company currently serves customers in the following industries: foundry, agriculture, military/defense, recreational vehicles, automotive, marine, heavy industry, construction, electrical equipment, plumbing and government. Winona is ISO9001, UL and JDM F17 certified. Visit WinonaPowder.com or call 1-800-476-9337.

Related Content

-

‘Warming Up’ to the Truth about Ovens for Surface Treatment

Understanding the different types of oven heat technology for surface finishing, including how they work, and their advantages and disadvantages, can help determine the best heating solution for an application.

-

Powder Coating Overcomes Post Forming

Six Sigma methodology, open communication, and collaboration produce results for leading boat manufacturer.

-

Oven Door Technology Improves Energy Efficiency

The RollSeal Door brings a compact, energy efficient and safe design to batch and conveyor style thermal processing units.