High-Temperature Treatment of High Phosphorus EN

Houston Plating & Coatings has added high-temperature heat treatment of electroless nickel plating to its broad line of corrosion and wear protection services.

Houston Plating & Coatings (Houston, Texas) announced that it has added high-temperature heat treatment of electroless nickel plating to its broad line of corrosion and wear protection services.

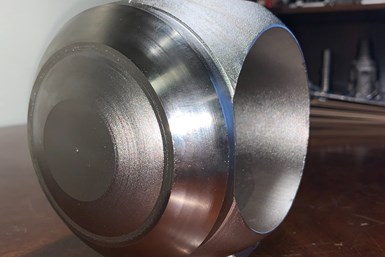

High phosphorus electroless nickel is widely used in applications due to its functional properties such as hardness, wear-resistance and corrosion protection. Applying a well-defined method of thermal treatment to the electroless nickel-plated steel substrate at temperatures above 600˚C further enhances these properties by forming a highly protective, thick, greenish oxide film and an interdiffusion layer with the substrate.

William Howard, CEO of HP&C, says “the benefits of this high heat treatment are substantial and include increased corrosion protection, hardness, deposit adhesion, deposit passivity, and resistance to abrasion. These are especially valuable for plated parts that will be in service in extremely corrosive environments.”

According to Eric Turner, COO and head of QC for HP&C, “this process generates three distinct barrier layers of protection that produce a significant improvement by the formation of a nickel oxide layer, a nickel phosphorus-rich layer and a nickel-iron diffusion layer which is continuous and ductile.”

The first interdiffusion layer occurs between the steel substrate and the deposited nickel-metal forming a Ni-Fe alpha phase. As this diffusion occurs, at temperatures above 550˚C, phosphorus migrates through the deposit toward the surface resulting in a Ni-P3 layer with larger nickel clusters forming a barrier to corrosion. The third outermost layer forms and consists of a nickel oxide layer.

Related Content

-

Innovation in Plating on Plastic

Plating on advanced plastics solution offers improved adhesion, temperature resistance and cost savings.

-

A Chromium Plating Overview

An overview of decorative and hard chromium electroplating processes.

-

3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.