PPG's Automobile Digital Styling Program Tests Light, Colors

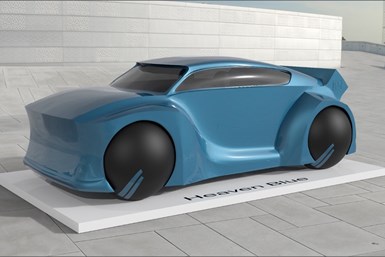

PPG’s new digital styling program for automobiles simulates PPG colors and effects on three-dimensional models of interior and exterior automobile surfaces.

PPG (Pittsburgh, Pa.) has launched a digital styling program, enabling automotive designers to perform realistic three-dimensional modeling of automotive colors and effects on virtual car designs and surfaces.

The company included its proprietary “speed shape” technology, which incorporates automobiles’ complex shapes, edges, curves and flat surfaces. PPG designed its digital vehicle model to depict the interaction of color, geometry and light, creating authentic renderings of a vehicle’s surfaces — including its wheels and interior components.

In addition to speed shape, the digital styling program offers automotive original equipment manufacturers (OEMs) complete access to PPG’s library of digital color files. It is also fully compatible with industry-standard color-rendering software, enabling OEM design teams to collaborate with PPG directly, remotely and in real-time on the color design process.

PPG says the program’s launch is the first step in digitizing the entire color styling process for its customers.

“Throughout the pandemic, PPG has recognized our customers’ increasing need for digital tools and technologies,” says Federico Menta, PPG’s global technical director of customer development for automotive OEM coatings. “Our industry-leading color experts have already used the program to conduct color styling sessions with several major OEM design teams. Many of those customers believe our program offers an effective alternative to managing the color-styling process in person. We believe it will enhance customer intimacy and create an opportunity for a collaborative color-creation process.”

“The ability to integrate new color ideas directly into the customer design process allows our customers to extract time and cost from color-rendering activities,” adds Rebecca Liebert, PPG’s executive vice president. “There are also other financial benefits associated with the program, including enhanced speed to market.”

Related Content

-

Curing Oven Basics

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...

-

Finishing Systems Provider Celebrates 150 Years, Looks to Future

From humble beginnings as an Indiana-based tin shop, Koch Finishing Systems has evolved into one of the most trusted finishing equipment providers in the industry.

-

TTX’s Automated Conveyor Carrier System Offers Wireless, Flexible Operation

ACC system designed for reliable, consistent point-to-point movement of everything from small to heavy parts.

.jpg;maxWidth=300;quality=90)