Solvent Kleene Releases Extreme Heat Resistant Powder Coating Remover

Solvent Kleene’s D-Zolve 917 facilitates the removal of extreme temperature resistant and chemical resistant powder coating.

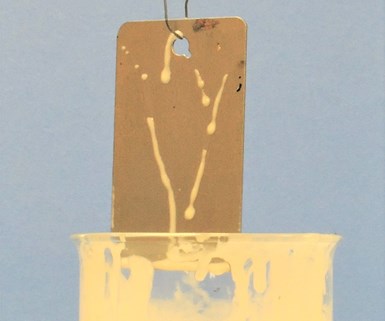

Before immersion in D-Zolve 917. Source | Solvent Kleene Inc.

Solvent Kleene Inc. (Peabody, Mass.) has released D-Zolve 917, a product designed to remove extreme temperature resistant and chemical resistant powder coating.

Extreme heat and chemical resistant powder coating is used in applications where it is important the coating withstand extreme temperatures without discoloring, losing gloss, adhesion or cracking. Because it has greater durability than ceramic coating and has been tested in temperatures up to 1200°F/ 649°C, removing chemical resistant high temperature powder coating can be challenging.

After immersion in D-Zolve 917.

D-Zolve 917 removes the powder coating from the surface of the substrate. The solution performs at low temperature of 110°F., is non-flammable, contains no methylene chloride or peroxides. The high temperature powder coating is removed by immersion with agitation followed by a quick water rinse.

Solvent Kleene Inc. | 978-531-2279 | solventkleene.com

Related Content

-

Reduced, Reused and Recycled Powder Coatings Are the Future

They say necessity is the mother of invention, and with millions of pounds of powder coating going into landfills a year, these two companies have found novel approaches to dealing with this waste stream.

-

Powder Coating 4.0: Smarter, Faster, More Efficient and Connected

New tools reduce cost and waste, lower manufacturing footprint of powder coating operations.

-

Curing Oven Basics

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...