ColWear Wear Plates Offer Exceptional Abrasion Resistance

Wall Colmonoy’s ColWear wear plates offer exceptional abrasion, heat and corrosion resistance while maintaining a light weight.

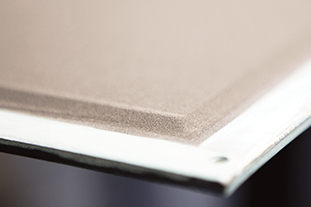

Wall Colmonoy’s (Madison Heights, Mich.) new range of ColWear wear plates leverages the company’s history of metallurgical expertise to provide a longer lifetime than traditional competitors. Vacuum-furnace production techniques improve the metallurgical properties of the alloy matrix, which consists of proprietary Colmonoy nickel and Wallex cobalt alloys with optional tungsten carbide.

Wall Colmonoy recommends using ColWear plates in industries where wear resistance is key, such as the chemical processing, power (waste to energy, biomass), steel, cement, mining and petrochemical industries. The company promises extended service life, with the reduced costs, maintenance and downtime that entails.

The company is proudest of the ColWear plates’ abrasion resistance, but also points out the plates’ heat and corrosion resistance as key selling points. Beyond simple industry recommendations, Wall Colmonoy recommends ColWear plates for abrasive processes such as separation, grinding and conveying.

Customers interested in lighter materials than traditional chromium carbide or tungsten carbide plate may also find benefits from ColWear plates, as the company says its plates are lighter and more uniform than alternatives.

Wall Colmonoy|248-585-6400|https://www.wallcolmonoy.com/

Related Content

-

An Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

-

How to Choose Between Sulfate and Chloride-Based Trivalent Chromium

There are several factors to consider when choosing between sulfate and chloride-based baths for trivalent chromium plating. Mark Schario of Columbia Chemical discusses the differences and what platers should keep in mind when evaluating options.

-

Products Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.