Wagner Expands Coatify IoT Platform and Debuts Light Version

Wagner has updated its Coatify IoT platform with newly compatible devices, new features that increase transparency on past jobs and a lower-priced feature-light version.

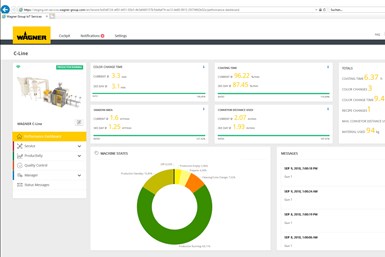

Wagner (Plymouth, Minn.) has updated its web-based information and management platform Coatify, which visualizes coating systems. The update for the IoT platform adds compatibility for new Wagner devices, introduces new features and debuts an entry-level version called Coatify.light. Users can securely access the platform via PC, tablet or smartphone to view production data from anywhere, any time.

Coatify provides visualized key figures, live productivity monitoring, spare part exchange information, operating instructions with a spare parts list and an interface for Wagner's remote maintenance service. The controls and sensors in Wagner products provide raw data, which transmits to Coatify via a secure connection. Wagner says this information enables reliable process control, short response times and anticipatory service measures.

New functions allow users to trace details of past jobs, including the used recipe, coating material and other parameters. This includes recording and tracing application data such as air and voltage settings from the EPG control units.

Another new feature displays the proportion of automatic to manual coating in the production process. The performance dashboard also displays both per-day and per-shift data, with automatic updates at regular intervals.

Wagner’s SuperCenter powder center and ELine variant, which has the maximum control scope of this coating line, are now compatible with Coatify, with more machines planned to follow.

The user can now also choose between two Coatify packages. In addition to the comprehensive complete package, which offers continuous data provision, the new version Coatify.light is available as an entry-level package with flexible billing models. It has a reduced range of functions, but still displays all data from the last 365 days. Wagner says companies can start with the lower-priced basic version and expand it when demands on their own production monitoring increase.

Wagner | 763-553-7000 | wagner-group.com/en/

Related Content

-

AkzoNobel Uses VR for Training Airline Apprentices

The virtual reality technology provides a paint booth and spray gun that enables trainees to work and master their skills without losing parts in the process.

-

Unlock Unparallelled Reliability

By prioritizing reliability in every aspect of its service offerings Dynapower ensures your equipment operates at peak performance levels consistently. With a steadfast focus on reliability, Dynapower’s field service, preventative maintenance and spare parts solutions ensure uninterrupted operations, minimizing scrap and maximizing uptime.

-

Top 5 Areas to Consider Automation of Plating Operations

Automation for finishing operations can lead to improvements in process time, repeatability and consistency of quality. Yet, processes that make sense to explore for these operational efficiencies may not always be readily apparent.

.jpg;maxWidth=300;quality=90)