2017 Hall of Fame Inductees

Frederick Gumm, John Horner, Dr. Leslie Lancy, John Lindstedt and Milt Stevenson Sr. were elected by a panel for their contributions to the surface finishing industry.

Five new members have been elected to the Products Finishing Electroplating Hall of Fame for their contributions to the surface finishing industry.

Frederick Gumm, John Horner, Dr. Leslie Lancy, John Lindstedt and Milt Stevenson Sr. were elected by a panel of industry veterans from nominations sent in by readers. They join the 16 members who have been selected over the past three years:

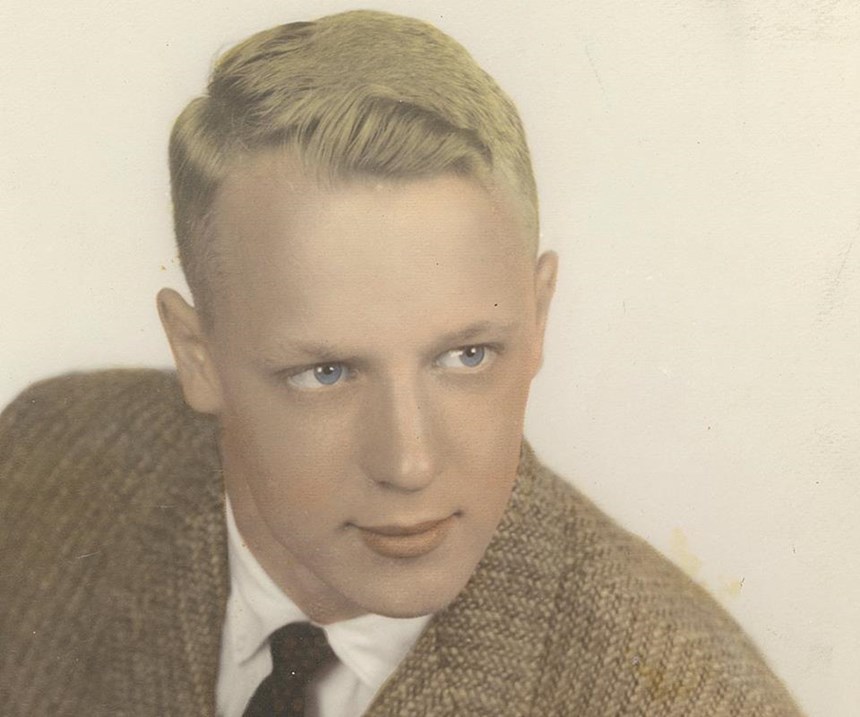

Frederick Gumm was CEO of Gumm Chemical Co. in New Jersey, where he not only led his family-owned company with its own chemical advancements, but where he helped acquire small companies with special technologies and joint ventured with international companies to bring important new technologies to North America, such as with Canning in the United Kingdom and Dipsol from Japan. Gumm was a mentor and industry leader to many in the surface finishing community.

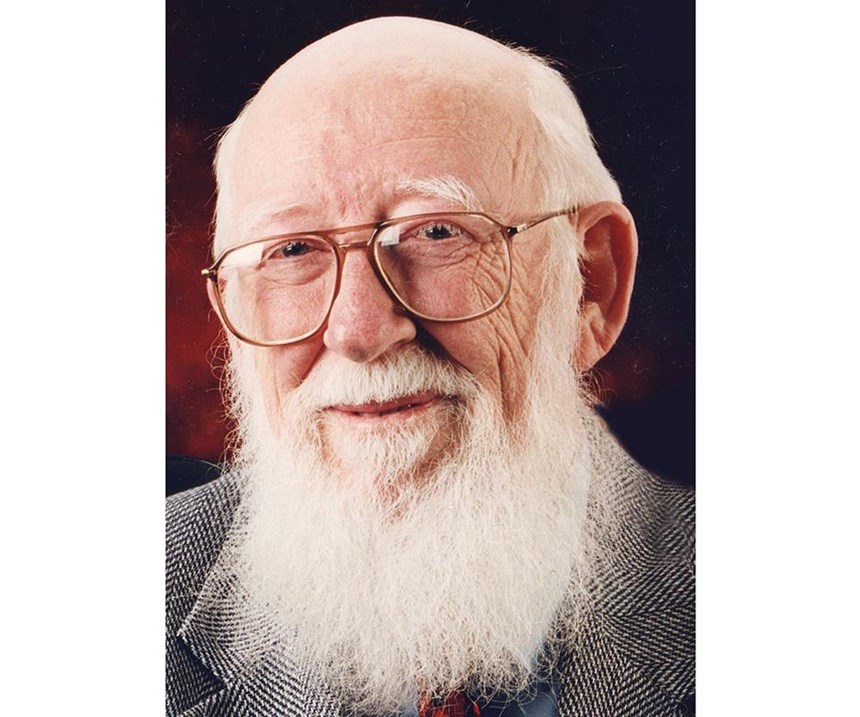

John Horner was technical director of Allied Kelite, where he wrote many training modules still used by the finishing industry today. He helped author technical service modules on copper plating, zinc plating and bright nickel plating that have been the basis for NASF modules used for CEF certification. Horner’s areas of expertise included included surface preparation, sulfamate nickel plating, copper plating and both electrolytic and electroless nickel plating. Horner was active in the AESF and ASTM, and since retirement had been consulting for the Nickel Institute. Horner died in March 2016.

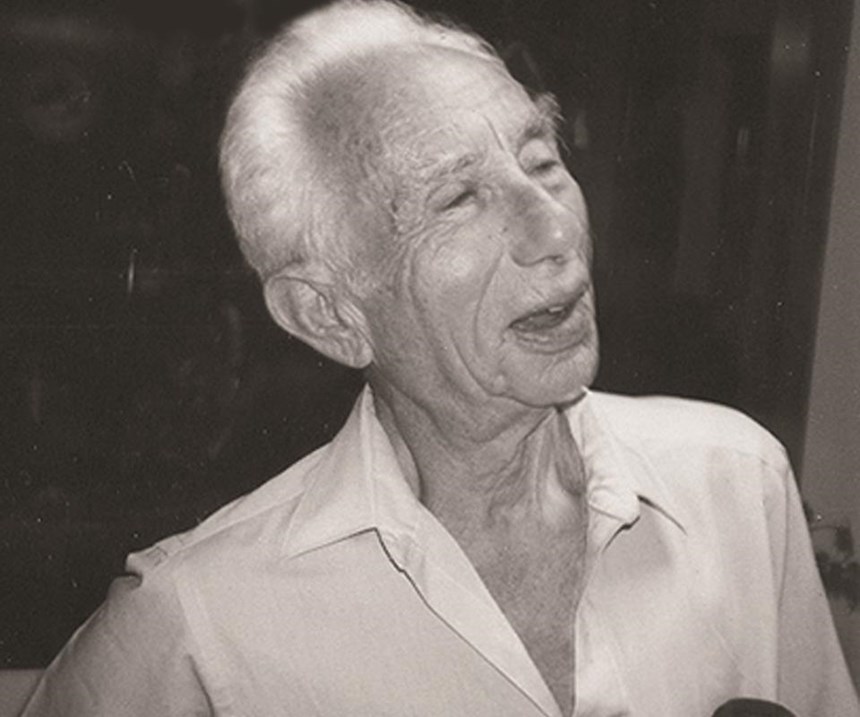

Dr. Leslie Lancy was a distinguished engineer and inventor whose main contributions were in the area of electroplating and waste recycling, specifically in his invention of the Lancy Integrated Treatment System, an idea to incorporate waste treatment into the manufacturing process as a substitute for the discharge of untreated wastes into a receiving stream or expensive end-of-the-pipe treatment. He was an advocate for what is called “Green Design” and “Industrial Ecology” two decades before the terms were coined. He died in 1996 at the age of 85.

John Lindstedt is president of Advanced Plating Technologies in Milwaukee, Wisconsin, where he has committed much of his 41-year professional career to the advocacy of the metal finishing industry through the Government Action committee within the NASF. He has actively engaged government at local, state and federal levels and has advocated for best practices consistent with sound analytical techniques. Lindstedt has served on the NASF Government Relations committee for over 15 years. His company has won numerous awards, including U.S. EPA Environmental Achievement Award, Milwaukee Metropolitan Sewage District High Honor Roll and the John C. Brogan Award for Outstanding Environmental Achievement from the Wisconsin Department of Natural Resources.

Milton Stevenson, Sr., was founder, president and CEO of Anoplate Corp. in Syracuse, New York. In his many years of service to the industry, he served on boards for both AESF and NAMF, and worked tirelessly to foster relationships across association boundaries such as the suppliers’ association MFSA and the National Tooling and Machining Association, serving various committees. He founded Anoplate in 1960 and under his leadership grew it to employ over 200 people, gaining an international reputation as a leader in the surface finishing industry. Stevenson received the Silvio C. Taomina Memorial Award, the NASF’s highest award, and was an emeritus trustee of Syracuse University. He died in 2009.

Balloting for the 2018 class will begin in the fall of 2017. For more information on the Products Finishing Hall of Fame, visit PFonline.com/zones/hall-of-fame.

Originally published in the February 2017 issue.

Related Content

Finisher’s ‘Top Shop’ Status Attracts Business

This competitive California finisher made it a goal to become a PF Top Shop. After earning the recognition, the company experienced an immediate increase in business and a challenge to obtain certifications.

Read MoreBryan Leiker, MFACA, Discusses CARB Public Hearing Over Calif. Hex Chrome Ban

Bryan Leiker, executive director, Metal Finishing Association of California, offers a recap of a January 27, 2023, public hearing conducted by the California Air Resources Board prior to an impending ruling on a proposed ban of hexavalent chromium use for finishing operations in the state.

Read MoreFinishing Systems Provider Celebrates 150 Years, Looks to Future

From humble beginnings as an Indiana-based tin shop, Koch Finishing Systems has evolved into one of the most trusted finishing equipment providers in the industry.

Read MoreTrivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

Read MoreRead Next

Episode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More

.jpg;maxWidth=300;quality=90)