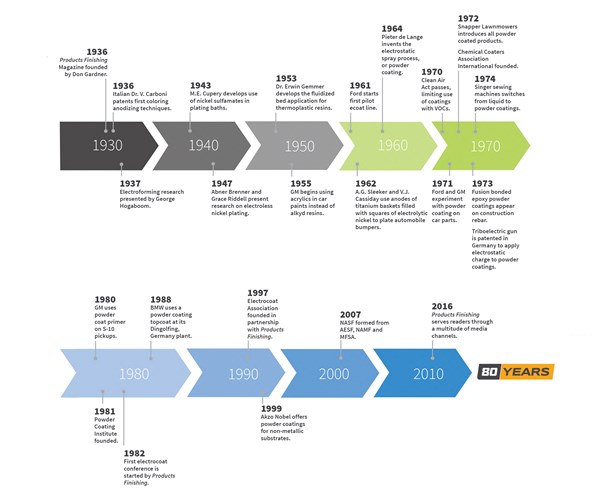

80 Years Helping Finishers

Our readers share how Products Finishing has helped their careers as the magazine celebrates its 80th year covering the finishing industry.

“Time passes, conditions change, the world progresses—

and those who are found keeping pace with the new order

of things are those who are young enough in mind and spirit

to recognize the value of the new and to make themselves a part of it.”

Don Gardner, Founder, Gardner Business Media

When Elliott Blackwelder began his electroplating career in 1982, he was amazed at what the industry did in the manufacturing cycle.

“I found it fascinating to take a piece of metal and make it shiny and more functional with nickel, chrome, zinc or the other types of plating,” he says.

When he asked his shop manager for reading material on the industry, he was handed a Products Finishing Directory and Technology Guide, the annual publication that contains articles on all types of finishing practices, in addition to lists of suppliers. He also began reading the magazine each month.

“Over time, it became my bible for practical electroplating knowledge, pre-internet,” says Blackwelder. “I used it extensively to fill in the gaps of the on-the-job training I received.”

Two years later, Blackwelder took an AESF course and became a Certified Finishing Professional. In 1987, he started his own shop, Seminole Metal Finishing in Altamonte Springs, Florida, and he used Products Finishing magazine and its technical directory to write training and apprenticeship programs for his shop employees.

“With Products Finishing and its Directory and Technology Guide, we use the articles that we find in the magazine in our weekly meetings to continue and further train all of our employees on the latest technologies and advice,” he says.

As Products Finishing celebrates its 80th year publishing all things finishing—from plating to liquid and powder coatings, electrocoating and anodizing to mechanical finishing—we have heard from many readers on just how important the magazine has been in their careers.

Many of our readers started out racking parts and working on zinc lines, and have now grown to become supervisors, managers and even owners, as Blackwelder has. We have compiled a few of our readers’ comments on how the magazine has helped them in their careers.

“I have been getting and reading Products Finishing for about 44 years. I go through each issue. I like the case studies very much and like to read about what different companies are doing to improve their finishing. The magazine is a great source of what is going on in our industry.”

- John Heyer; President, Kettle Moraine Coatings

“Whenever we have faced a particularly challenging issue in the painting of our products, we typically search for case studies or information on the web. On many occasions, a past story or article in Products Finishing on the same topic had just the insight we needed to get started on root-cause determination and corrective action plans. There is no doubt the 80-year history has built up a vast volume of examples and expertise from which to draw upon.”

- Scott E. Maki; Vice President, Custom Products of Litchfield

“Products Finishing has been helpful not only in the technical aspects of my job, but also in keeping up with the industry, new products and key persons. I remember one of the first articles I read; it was on electroless nickel that came out around 1997. I had just started working at one of the big EN suppliers at the time and the article clarified a lot about the technology. I also really like the profiles, which put a human face on our industry. It’s just a great read about an industry I care about very much.”

- Robert B. Mason, Jr. ;CEF, PMP, ACG Concurrent Technologies Corp.

“Products Finishing is my favorite trade magazine and I’ve read almost every issue for about 60 years. In 1975, when I was being trained as a newly hired field engineer for Wheelabrator Corp. in Mishawaka, Indiana, my supervisor told his class of trainees that reading every issue of Products Finishing would give us a wide knowledge of manufacturing processes, and make us increasingly valuable to our employer and to our customers. I followed that advice, and to this day I often surprise myself by the contributions I make to customers regarding a variety of processes.”

- Steve Marcus; CMfgE, Chairman, Markee International Corp.

“I’ve been reading Products Finishing for my entire 30-year career, and most everyone else in management at SAF enjoys it as well.”

- Penn McClatchey; Co-Chief Executive Officer, Southern Aluminum Finishing Co.

Originally published in the December 2016 issue.

Related Content

Products Finishing Reveals 2023 Qualifying Top Shops

Each year PF conducts its Top Shops Benchmarking Survey, offering shops a tool to better understand their overall performance in the industry. The program also recognizes shops that meet a set of criteria to qualify as Top Shops.

Read MoreProducts Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read MoreMasking Solutions Provider CFS Dramatically Expands Capabilities and Capacity

Custom Fabrication & Supplies (CFS) completed a new plant expansion packing 10 times the capacity into twice the space. It dramatically enhances the supplier’s custom capabilities to provide extremely precise and cost-effective masking solutions.

Read MoreReduced, Reused and Recycled Powder Coatings Are the Future

They say necessity is the mother of invention, and with millions of pounds of powder coating going into landfills a year, these two companies have found novel approaches to dealing with this waste stream.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More