A Conversation With ...Zoie Aiken

Division of Microbial Diseases, UCL Eastman Dental Institute

A light-activated coating that can ward off infectious disease and keep patients safe? The technology is closer than you think. Medical coatings of the future are in the hands of today’s research scientists—like Zoie Aiken, a Ph.D microbiology student from London, England. This spring, she and her colleagues, a mix of chemists and biologists, presented their research at a meeting for the Society for General Microbiology in Harrogate, England. Between balancing lab work and researching literature, Zoie found time to chat with us about her ground-breaking work on light activated antimicrobial coatings.

Tell us about your research.

Z.A. My research is based on the assessment of new antibacterial coatings. Our current coating has been shown to kill 99.9% of E. coli bacteria when a white hospital light is shone on its surface to activate it.

What are some of its potential applications?

Z.A. The hospital environment acts as a reservoir for the microbes responsible for health care-associated infections (HCAI), and new ways of preventing the spread of these pathogens to patients are needed. Antibacterial coatings could be applied to frequently touched hospital surfaces to kill any bacteria present and help reduce the number of HCAI.

The coatings have a large amount of potential because as long as there is light present for a sufficient amount of time, the coatings will become activated. Once the coatings are activated, they are able to kill E. coli bacteria. We plan to test the activity of the coating against a range of different bacteria such as methicillin-resistant Staphylococcus aureus (MRSA) and other organisms known to cause infections in hospitals. At present, we only know that the coating is active against E. coli. However, E. coli is more difficult to kill than bacteria from the Staphylococcus group, which includes MRSA, so the results to date are encouraging.

What would you consider your biggest breakthrough?

Z.A. Tuning the chemical properties of the coating material so that light available in hospitals can be used for activation. Similar technology needs high concentrations of UV light for activation, not present indoors.

What do you envision the coatings may be able to accomplish in the next five years?

Z.A. In the next five years the coatings could be applied to a range of substrates, which would increase the number of practical uses. We are already experimenting with plastic, so the coating could be applied to a plastic sheet that could be used to cover a computer keyboard on a hospital ward. The lights in the ward will keep the coating activated, which will in turn continue to kill any bacteria that may be transferred onto the keyboard from the hands of health care workers.

How about further down the line—say 20–50 years? Dare to make any predictions?

Z.A. In 20–50 years all hospital surfaces could be coated. This technology can conceivably be applied to glass, metal and wood or even mixed in paint. The potential therefore exists to coat many of the surfaces, including in doors, floors, walls, etc. These coatings have a great number of potential uses outside of the hospital environment, for example in a multitude of industries such as food preparation areas, bathrooms and in the home.

Related Content

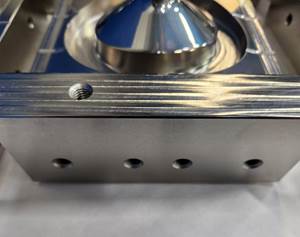

Engineered Coatings Offer Improvement for Medical Device Manufacturers

Diamond electroless nickel coating provides better lubricity and improved wear resistance for molds, resulting in better quality and productivity.

Read MoreFinishing High Reliability, Function Critical Parts

From safety critical automotive and aerospace components to lifesaving medical micro-components and implantable devices, Indiana-based Electro-Spec finishes applications that require zero failure rates.

Read MoreSilica-free Abrasive Compounds Offer Improved Health, Safety

Osborn has a line of silica-free abrasive compounds that offer both employee and environmental benefits.

Read MorePrecision Coating Receives ISO 14001 Certification

The company says its commitment to the environment and its health led it to seek this certification.

Read MoreRead Next

Episode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More

.jpg;maxWidth=300;quality=90)