Abrasive Blasting Guides for the Ages from Clemco

Clemco Industries Corp. wrote the book on abrasive blasting (and made the movie). Get a copy or watch the movie and see how things have changed in 60 years.

For nearly 60 years, Clemco’s Blast Off and then Blast Off 2 have been the gold-standard, pocketbook, reference manuals for the abrasive blasting industry. That’s why more than 1 million copies have circulated around the globe in numerous languages. Clemco distributors across the country for decades have used the booklets as training tools for their staffs. Industry educational organizations such as the Finishing Trades Institute and Contractor Campus have used the booklets in their classrooms. However, you’re even more likely to find the booklets in the pockets of operators in the field.

The manual for abrasive blasting

Blast Off was first published in 1963. As the abrasive blasting industry evolved, so did Blast Off. It went through several revisions, and the current edition is now titled Blast Off 2. It covers everything from how to position a blast machine, how to choose the best nozzle for a job, how to use safety equipment and to identify potential safety hazards, an overview of the elements of a complete blasting system, and every other imaginable topic in between.

In 1997, Clemco published the first edition of Abrasive Blasting Safety Practices. Subsequent editions of this booklet have become as popular as Blast Off 2. Both Blast Off 2 and Abrasive Blasting Safety Practices also are published in Spanish.

Clemco offers free copies of its manuals for workers in the industry. Request your copy of Clemco’s safety and training books here.

16 mm films—In color!

Shortly after Clemco published the first edition of Blast Off, it produced two films that illustrated the booklet’s content: Blast Off the movie and the ABC’s of Surface Preparation. Clemco literature at the time proudly advertised free showings of these two 16 mm color films.

Through the magic of modern technology, Clemco has converted these 16 mm films into digital format. Before viewing these films, remember that Clemco was originally a division of Clementina, a contractor equipment-rental business headquartered in San Francisco, which is why San Francisco backdrops prominently appear in these films. So sit back, relax, and enjoy a bit of blasting industry nostalgia (in color!).

In the 1950s, Clemco (sometimes under the Clementina name) began publishing information about the abrasive blasting industry. Two notable booklets were Sandblasting with Clemco and Sandblasting from a Practical Standpoint, which on Page 1 describes the “Similarity of a Shotgun with Sandblasting.” Today, the abrasive blasting industry recognizes that sand should NEVER be used in abrasive blasting operations because of the respiratory hazards associated with the use of abrasive containing free silica. Breathing abrasive containing crystaline (free) silica can lead to serious or fatal lung disease. However, this was standard practice at the time.

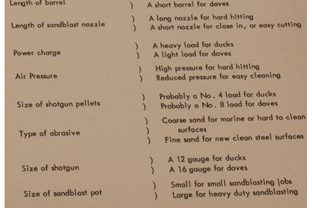

Within the booklet, several colorful comparisons were made between hunting with a shotgun and blasting with a Clemco machine, such as:

An excerpt from Sandblasting from a Practical Standpoint

- Length of barrel

—A long barrel for ducks

—A short barrel for doves - Length of sandblast nozzle

—A long nozzle for hard hitting

—A short nozzle for close in, or easy cutting

Read Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More

.jpg;maxWidth=300;quality=90)