AI-Powered Robotic Solutions Support High-Mix Finishing

AI startup offers automation innovations for high-mix, high-variability, manual surface finishing applications.

Finishing processes such as grinding, sanding, painting, polishing and buffing can be highly repetitive and physically demanding tasks. Yet, despite its repetitive nature, most surface finishing work has traditionally been performed by hand, particularly in the composites industry. Automation solutions may seem like an obvious remedy for this overarching problem, but unfortunately the answer isn’t always that easy. Robots can help when you have repetitive tasks on high-volume production lines, but tend to raise a host of considerations when processing a diverse mix of parts that come in a variety of sizes and shapes, which is often the case for composites fabricators.

GrayMatter Robotics (Gardena, Calif., U.S.) is a startup dedicated to solutions to address this very dilemma. The company was founded by CEO Ariyan Kabir, CTO Brual Shah and chief scientist Satyandra Gupta based on insights gained during their studies at the University of Southern California (USC). Kabir says interactions and experiences gleaned from USC’s strong industry-affiliated programs provided insight into challenges in manufacturing centering around the shortage of skilled labor, the need for consistent quality and repeatable results.

While workforce challenges are nothing new in the world of manufacturing, numerous factors have exacerbated the problem in recent years including the COVID-19 pandemic and subsequent workforce dropout. On top of the skilled labor shortage, manufacturers are struggling with high demand from their customers, contributing to long lead times.

For Kabir, coming from a background studying robotics, the solution to many of these problems seemed obvious: robots.

The problem with robots

Kabir and his colleagues found themselves asking companies in a range of markets from aerospace to industrial to commercial why they weren’t turning to automation solutions more often. The answer was an eye-opener, not only to the complications that can stand in the way of installing a robot on the production line, but also to just how far-reaching the problem really was.

The crux of the problem, they discovered, is high-variability manufacturing. Unless you’re dealing with high-volume production with repeatable processes, implementing robotics and automation solutions can be difficult to justify for some businesses. High variability in manufacturing processes often requires rapid adaptation to changes in product design or production requirements. Traditional robotic systems may struggle to quickly reconfigure or adapt to variations, leading to inefficiencies. In addition, robotic systems typically require precise programming to perform specific tasks — a proposition that can be complicated and time-consuming.

“We learned that you can’t really use robots the way you use them in automotive or electronics manufacturing, where you have hundreds or thousands of identical parts,” says Kabir.

The team now had a broader view of the manufacturing world where 90% of the work features a lot of variability from part to part, including variation in the materials and/or manufacturing processes being used. However, this deeper understanding of the obstacles to implementing automation did nothing to deter Kabir and his colleagues. They still believed the solution to solving workforce and quality issues lay in automation solutions — and now they better understood the challenge.

“Okay — so if robots have to work on these jobs, robots need to become autonomous. They must be able to make decisions on the fly with minimal instruction — they must be able to perceive the job and execute it successfully,” says Kabir. “That realization pushed us into thinking how can we create technology that can enable robots to program themselves.”

Enter AI

In 2017, Kabir and his colleagues participated in a competition organized by robotics company KUKA (Augsburg, Germany) — the Kuka Innovation Award. The group was given a booth at the Hannover Messe industrial trade show where they showcased a two-robot finishing cell based on their programming. The team found themselves talking with a variety of manufacturers and fabricators from a wide range of industries about how the technology could be used in production. Then in 2019, the group conducted a customer discovery program, funded by the National Science Foundation in the U.S, and interviewed more than 150 people from the manufacturing ecosystem. Kabir says it soon became apparent that adapting automation for high-variability manufacturing was a global problem affecting every industry.

In 2020, the group founded GrayMatter Robotics with a focus on the automation of different tools prevalent to manual surface finishing operations including sanding, polishing, grinding, buffing, painting, coating, deburring, trimming, sandblasting and laser ablation.

“There are hundreds of robotics companies focused on material handling applications — pick and place, assembly, moving parts from one place to the other,” says Kabir. “But there was virtually no one addressing the high-mix, high-variability surface finishing and surface treatment applications within manufacturing at that time.”

GrayMatter built its business on creating artificial intelligence (AI) technologies that enable robots to program themselves to perform these operations. The company integrates its software into smart robotic cells designed to assist humans in tedious and ergonomically challenging tasks.

“We are not making the robot, sensors or the tools,” explains Kabir. “We take commercially available, off-the-shelf robot sensors and tools, and we look at an application and identify what would be the best fit. And then we bring that equipment and combine it with our physics-informed AI technologies and other software technologies.”

Companies such as 3M (Saint Paul, Minn., U.S.), that provides a range of abrasives and surfacing tools, and robotics provider FANUC America (Rochester Hills, Mich., U.S.) partner with GrayMatter to design automation cells for their customers.

“Our industrial customers around the world continue to pivot to automated grinding and finishing solutions,” says Carl Doeksen, global robotics and automation director for 3M. “GrayMatter Robotics augments 3M’s innovation model in this space. GrayMatter has the creative AI, mechatronics and software horsepower, to compliment 3M’s application engineering and material science capabilities. Our customers that have deployed the GrayMatter solution — and there are several — see immediate improvements in the environment for their workers, productivity and quality/consistency. Practically every industrial factory does some type of manual grinding or sanding today [and] GrayMatter is transforming these applications, shaping the future of manufacturing.”

GrayMatter Robotics’ solutions are designed so that an operator can bring a part in front of a robot and simply press a button on the touchscreen.

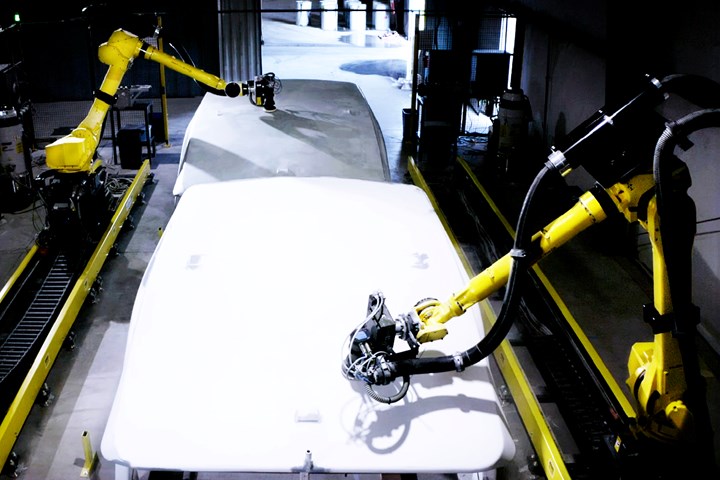

Customers typically sign a contract and are given access to the full turnkey package for a flat monthly or annual fee. The solution makes it possible to run a variety of finishing operations on a wide range of part configurations. Kabir says examples of composite parts that GrayMatter has worked with include everything from fiberglass boat hulls and architectural parts to carbon fiber aerospace components and automotive parts. The robots scan the part, determine the geometry, account for the surrounding environment (the cell), write a program and start running the operation. The system works solely from the live scan data and does not require a CAD model.

Manually programming a robot to perform such operations can involve generating hundreds of data points per part. This kind of work can sometimes take a human programmer weeks. Kabir says GrayMatter’s AI software is capable of scanning parts and generating these data points in minutes, depending on the part geometry. Onboard sensors scan parts and automatically generate a model using the company’s proprietary GMR-AI software. This model then programs a robot to autonomously execute the desired surface treatment operation. During the execution of the process, the sensors provide constant feedback, allowing the robot to adapt and adjust its movement to prevent mistakes and to ultimately guarantee consistency and quality.

Kabir describes GrayMatter’s approach to AI as a full stack solution. “We use different AI technologies at each and every layer to understand the world and the part and the job,” he says. “First, we have to understand the part and everything around it. Then we must figure out how to move the tool to do the right job, safely and efficiently. Then we must guarantee the system uptime, making sure the system is available for use as much as possible.”

This translates into prognostics and health monitoring of the system, as well as the ability to autonomously recover. The robot can call for help from a GrayMatter support technician 24/7 and usually, with the press of a few buttons, operation resumes in a matter of minutes.

Nathan Scheer, director of innovation for Patrick Industries Inc. (Elkhart, Ind., U.S.), a component solutions provider for the RV, marine housing and powersports industries says GrayMatter’s “low code or no code” technology plays a big role in helping with the company’s bandwidth in robotics. The company uses GrayMatter’s Scan and Sand technology for producing such parts as glass fiber-reinforced polymer (GFRP) RV roofing components and marine hard tops. “With the growth of automation, the lack of available skilled human capital can be a barrier for many companies,” says Scheer. “By embracing this technology, we can mitigate that hurdle. When I saw the opportunity to perform programming autonomously, reduce maintenance, and enable remote monitoring and support, I was very intrigued.”

Despite the complexity and versatility at each stage of the process, the core idea of GrayMatter’s approach is that anyone can bring a part in front of a robot and simply press a button on the touchscreen. For example, for a sanding application, the part is placed in the robotic cell and a “Scan and Sand” button is pressed.

“We design the solution for shopfloor operators — someone who has no knowledge of robotics or programming,” says Kabir. “Therefore, we create a solution that’s very simple to use.”

A good fit

GrayMatter Robotics provides artificial intelligence (AI)-driven software designed to enable robots to program themselves to perform surface finishing and surface prep operations for a wide variety of part sizes and shapes.

GrayMatter’s solutions are designed to accommodate a wide variety of part sizes and shapes. More importantly, it can be something that the robot has never seen before. “It can be a football helmet, a hull of a boat or a fuselage of a fighter jet,” Kabir says.

In addition, the company’s solutions can be materials agnostic, applicable for surface finishing on a range of substrates from metals such as aluminum and stainless steel to acrylics to wood. Yet, Kabir says, more than 50% of GrayMatter’s customers are in the composites industry.

What makes the company’s solutions such a good fit for composites? Kabir says it’s the ability to adapt to variation. The bespoke nature of many composite parts makes the ability to scan and process singular parts an advantage. “Part variation and variability is very high,” says Kabir.

Jacob Cartwright, director of engineering for McClarin Composites (Hanover, Pa., U.S.) says GrayMatter’s solutions have helped alleviate the complexity associated with traditional automation. McClarin manufactures large complex composite parts for use in many different markets including infrastructure, transportation, architecture and marine. The company fabricates parts via several different processes including thermoforming, reaction injection molding (RIM), open mold, light resin transfer molding (LRTM), and vacuum assisted resin transfer molding (VARTM), among others. The company uses thermosets, thermoplastics, glass fiber, carbon fiber and basalt fiber composite materials. Cartwright says the products currently being manufactured on the GrayMatter system range from open molded GFRP hoods for the heavy truck industry, and closed mold GFRP covers for the transportation industry.

“We have a high-mix environment with medium-volume production. But in such an environment, traditional automation struggles,” says Cartwright. “There’s a lot of rigid programming and fixturing that you need to deploy in order to be successful. The GrayMatter technology fits a niche for us; it allows us to combine increased volume with increased production as well as complexity. We can do that and not have to conform to traditional automation, which is more rigid. We have five axis routers that run all day, every day manufacturing higher volume products — the fixturing is rigid, the programming is rigid. In a traditional machining process or traditional automation process, we would have to ensure that there are safeguards in place, making sure that the correct program is installed, and the correct fixturing is installed. GrayMatter’s technology differentiates itself from traditional automation by building [and managing] its own complexity.”

The whole idea is to make robotics accessible for fabricators who finish their own parts, and also for finishing operations dealing with numerous low-volume production programs. AI-powered robotics not only improve consistency and quality, notes Kabir, but also use 30-50% less consumables than manual methods.

In 2022, GrayMatter earned the RBR50 Innovation Award, given to the most creative and influential innovators advancing the state of robotics worldwide. Interest in the company’s solutions is on the rise. With 53-80% of its current team being engineers, Kabir says the company is growing at a rapid pace and he expects staffing to have doubled by the end of the year. And the work, says Kabir, is coming from aerospace, transportation, marine, sports equipment, musical instruments, architectural products and more. “It’s a platform solution for a very wide range of industries and applications.”

Related Content

Best Practices for Blast Room Maintenance

A high-quality blast room is a large investment. Brandon Acker of Titan Abrasive Systems discusses proper care for your blasting equipment.

Read MoreModernizing Wastewater Treatment and Recovery

Source: Kontek Kontek’s “spigot to drain” Source Water and Wastewater Solutions offer integrated technologies to modernize your water & wastewater treatment and recovery.

Read MoreHubbard-Hall Technical Team Adds Senior Chemist to Staff

David Keller is joining the Hubbard-Hall technical team as a senior chemist.

Read MoreUnderstanding Shot Peening

A look inside shot peening — a process of “hammering” of work pieces with precisely defined blast media.

Read MoreRead Next

Loop Technology performs robotic feasibility study for Solidwool

The study revealed significant process efficiencies, reduced waste and a high-quality surface finish after trimming excess material from a Solidwool composite chair.

Read MoreUpdate: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read More