Alternative to Traditional Alkaline Cleaners Lowers Costs

To lower cleaning costs, consider switching from your current alkaline cleaner to a true neutral pH cleaner.

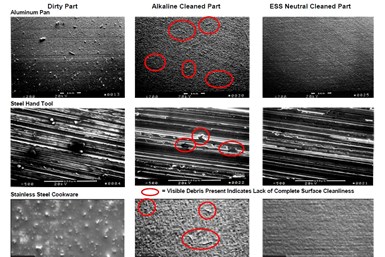

These electron microscope photos show that true neutral cleaners clean better than alkaline cleaners. Source: Environmentally Sensitive Solutions Inc.

Q. How can I lower operating costs on my parts cleaning process without sacrificing cleanliness or quality?

A. While there are a number of ways to tighten up a parts cleaning process to reduce operating costs (for example, upgrading wash/drying equipment and utilities), one of the easiest ways might be to switch from the current alkaline cleaner to a true neutral pH cleaner. True neutral cleaners are not watered-down alkaline cleaners with sodium bicarbonate (baking soda) replacing sodium hydroxide (caustic), although the industry sometimes refers to them that way. A true neutral cleaner has a neutral pH of 6.5 – 7.5, both concentrated and diluted.

Alkaline cleaners have been around since the 1960s to replace solvent cleaners and are by far the most commonly used parts cleaning product for cleaning a variety of parts in a variety of washer styles. Acidic cleaners are used to clean/brighten and deoxidize parts in more niche parts applications. Solvents are still used on occasion, although on a limited basis for specific applications.

True neutral cleaners evolved about 35 years ago as a viable and cost-effective replacement for alkaline cleaners. True neutral cleaners are used in a variety of cleaning equipment styles including spray, immersion, rotary drum, vibratory, ultrasonics and pressure washers. True neutral cleaners have successfully cleaned the gamut of industrial parts processing soils, including synthetic coolants, semi-synthetic coolants, chlorinated paraffin oils, machining oils, buffing compounds, drawing compounds, among others.

There are many ways properly formulated true neutral cleaners can eliminate costs generated using traditional alkaline cleaners:

- Wastewater simplification and reduction: True neutral cleaners automatically split oils for recovery, eliminate heavy metal solubilization and do not require pH neutralization prior to discharge. Oftentimes, wastewater generated by true neutral cleaners is categorized as non-regulated.

- Better part quality for less rework and scrap: True neutral cleaners rinse better with less residue and less rinse water needed. Neutral pH eliminates potential etching of soft metals without the need for silicates, so white rust on metals like aluminum is eliminated. The quality of post-cleaning part bonding processes can be dramatically improved (with less scrap) because the surface to be bonded is cleaner and contains less residue when washed with a true neutral cleaner.

- Multi-metal safe: True neutral cleaners can be safely and interchangeably used on any type of metal part, including aluminum, brass, copper, stainless steel, steel (among others) without the need for silicates of alkaline cleaners. Neutral cleaners can reduce the number of different alkaline parts cleaning products for various metal types.

- Wash bath-life extended: True neutral cleaners automatically split oils (once bath agitation stops) for easy skimming and recovery, thus extending bath-life for reduced cleaning costs.

- Reduces wash equipment wear and tear: True neutral cleaners significantly reduce the residue build-up in wash equipment and the labor needed to routinely clean nozzles and regularly maintain washers. The ongoing expense of acid boil-outs is eliminated.

- Worker safety and protection: True neutral cleaners almost eliminate the chance for worker injury because of chemical exposure from high pH alkaline cleaners. The neutral pH cleaner is non-corrosive and non-hazardous, vastly simplifying worker chemical training, personal protection equipment and expense.

- Product simplification: Alkaline cleaners often require additives like wetters and defoamers to be purchased and added separately tank side for the alkaline cleaner to function properly. True neutral cleaners eliminate those additives in that wetting and foam control is built into the formulation itself.

- Lower freight costs: Because they are not limited by ingredient solubility issues like alkaline cleaners, true neutral cleaners can be super concentrated to 2x and beyond to cut freight costs. At a 2x concentrate, it is like getting two drums in one, which cuts freight costs almost in half.

- Greener alternative: As parts manufacturing companies are “greening” up their products and processes, true neutral cleaners can play a hugely positive role in that narrative by being more environmentally friendly than alkaline cleaners without sacrificing performance.

True neutral cleaners are a drop-in replacement for alkaline cleaners in most parts cleaning applications. Other than some initial cleaning of an alkaline washer switching over to a neutral cleaner, true neutral cleaners simplify wash processes and reduce costs.

About the Author

Matt Pliszka

Matt Pliszka is a true neutral cleaner formulating pioneer and parts cleaning expert, with a 37-year track record of success at Environmentally Sensitive Solutions Inc. (ESS). Visit neutralcleaner.com for more information.

Related Content

Corrosion Resistance Testing for Powder Coating

Salt spray can be useful to help compare different pretreatment methods and coatings but it does not tell us much about the corrosion resistance of a part over time in the field. Powder coating expert Rodger Talbert offers insights into how to get a better idea of how to improve a part’s corrosion resistance in the real world.

Read MoreTop Reasons to Switch to a Better Cleaning Fluid

Venesia Hurtubise from MicroCare says switching to the new modern cleaning fluids will have a positive impact on your cleaning process.

Read MoreSolvent Versus Aqueous: Busting the Myths

Is aqueous cleaning “greener” than solvent cleaning? Is solvent a more effective cleaner than aqueous? These and many other questions are answered here to debunk the misconceptions that many manufacturers have held onto for years.

Read MoreFrom Drain to Gain with Smart Wastewater Recovery

Incorporating digital monitoring to maximize performance.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More