Water is integral to many industrial metal finishing and fabrication processes. Because of the nature of the substrates processed and the chemistries used, treatment of the wastewater is typically required whether the wastewater is discharged or reused within the facility. Treatment for reuse sounds like a good idea, and many times it is, but there are things to think about and evaluate before committing to this avenue. This includes

Service-based wastewater ion exchange (WWIX) treatment uses leased, service exchange tanks. The tanks are used onsite for wastewater recovery treatment and, when spent, are replaced with fresh resin tanks with the spent tanks returned to a central processing facility for regeneration. This system relies on the customer to monitor the system for performance and to call into the service center for tank exchanges. Photo Credits: Evoqua

using newer technologies that incorporate digital monitoring that provides users with consistent and reliable recovered water quality, minimizes user involvement and provides access to historical water quality data.

Production and water quality

In metal processing industries, water is used for multiple reasons including makeup of process chemistry, rinsing of parts to remove process chemicals and soils, quenching and quality control (QC) processes such as hydrostatic testing. It is helpful to understand some general terms that describe water quality:

- City or well water: water from the tap with the full complement of background constituents

- Soft water: treated to remove hardness (calcium and magnesium)

- RO water: treated to remove the majority of the background constituents

- Deionized water: treated to remove virtually all of the background constituents

Water quality may be measured in several ways; the typical water quality expressions include:

- Total Dissolved Solids (TDS): the concentration of salts, metals and minerals dissolved in water — a lower number indicates cleaner water

- Conductivity: how well the water conducts electricity; expressed as micro-Siemens/centimeter (micro-S/cm) — a lower number indicates cleaner water

- Resistivity: how well the water resists the flow of electricity; expressed as megaohm-centimeter (MΩ-cm) — a higher number indicates cleaner water

These water quality measurements are all related; a comparison is shown in Table 1.

|

Table 1. Water Quality Measurement Comparisons |

||

|

TDS (ppm) |

Conductivity (micro-S/cm) |

Resistivity (MΩ-cm) |

| 5 |

10 |

0.1 |

|

0.5 |

1 | 1 |

|

0.028 |

0.056 |

18 |

The key to maximizing water usage and treatment cost is to match the water quality to the requirements of the particular process. A phosphating process might be just fine using city, well or soft water, while a critical cleaning application may require deionized water. Using water that is not clean enough can cause issues such as poor rinsing of soils and subsequent spotting of parts from residual water constituents. Conversely, water that is too pure can also be problematic in that highly purified deionized water can be aggressive toward certain metal substrates such as copper, for example.

Wastewater generation and recovery

Metal finishing and metal production processes generate an array of contaminants. Regulated heavy metals (cadmium, copper, nickel, lead, zinc), both particulate and dissolved, are common as well as typically non-regulated metals (calcium, magnesium, potassium, sodium). Other common contaminants include particulates (soils, scale, metal part substrate components), oil and grease (machining oils) and other organic compounds (chemical bath primary chemistry or breakdown components).

Metal finishing and processing wastewaters are most commonly treated to meet discharge regulations — the treatment reducing the regulated contaminants in the wastewater to below the concentrations designated in a facility’s industrial wastewater discharge permit. Taking the next step — treating wastewater for recovery and water reuse — requires the removal of both the regulated and non-regulated contaminants.

There are a number of things to consider when contemplating wastewater recovery for reuse. Water recovery and reuse can reduce the amount of water your facility takes in and discharges which can improve the facility’s sustainability footprint. It may be possible to remove a problematic waste stream from the facility discharge. It is also important to vet the impact of using recovered water in the processes for which it is intended to ensure that no components of the wastewater might be detrimental to the process should those components pass through the treatment system.

Treatment options

There are several unit operations that can be used to treat wastewater for reuse and recovery. The most common primary processes are ion exchange (IX) and reverse osmosis (RO); adjunct processes to support IX and RO include carbon adsorption, filtration and ultraviolet (UV) light treatment.

Ion exchange (IX) treatment is an established technology that uses polymeric beads in a pressure vessel through which the wastewater is passed. The IX resins contain charged functional groups; these functional groups will exchange cations (positively charged species) and anions (negatively charged species) between the resin and the wastewater. In water reuse and recovery applications, the resins adsorb contaminants from the waste stream and replace the contaminant ions with hydrogen (H+) and hydroxide (OH-) ions which combine to form water. Mixed bed IX can deliver highly purified water up to 18.2 megohm (MΩ-cm) or essentially zero total dissolved solids (TDS). When the IX resins are spent, they are regenerated using acid and alkali and returned to service; all contaminants removed by the resin are transferred to the acid and alkali regenerant streams which will require treatment prior to discharge. IX is the most common recovery technology, especially for small flowrates.

Reverse osmosis treatment is also a tried-and-true technology that uses a membrane barrier to separate contaminants from the waste stream. A pump pressurizes the waste stream and forces water through the membrane leaving most of the contaminants behind. The clean stream, or product stream, is recovered and can be used as-is or further polished with IX treatment. The dirty stream, or concentrate stream, can then be discharged or potentially reused somewhere where the higher level of contaminants will not be problematic. Since RO produces a concentrate stream, it is important to understand the composition of the waste stream to determine if it requires further treatment prior to discharge or reuse.

Carbon adsorption is a technology used to remove organic compounds from water (typically measured at Total Organic Carbon or TOC) as well as small amounts of oil and grease (O&G). Wastewater is passed through a pressure vessel containing granular activated carbon (GAC); the TOC and O&G adsorb to the carbon’s surface. When the carbon is spent, it is typically disposed of and replaced by fresh carbon. Both IX and RO use GAC as a pretreatment to remove the TOC and O&G that can foul the IX resins and RO membranes.

Filtration uses a physical barrier, such as bags, cartridges or a graduated media, to remove total suspended solids (TSS) from the waste stream. Filtration is also used as a pretreatment for IX and RO as these technologies are adept at removing TDS but can be fouled by TSS.

Ultraviolet (UV) light is used on very high purity recovered wastewater to control either bacterial growth or low levels of TOC; bulbs generating UV light of differing wavelength are used depending on which of those contaminants require control.

A listing of the technologies, the contaminants that they remove, and whether they are typically used as primary or adjunct treatment is shown in Table 2.

|

Table 2. Wastewater Recovery Technology Comparison |

||

|

Technology |

Contaminants Addressed |

Primary or Adjunct |

|

Ion Exchange |

TDS |

Primary |

|

Reverse Osmosis |

TDS |

Primary |

|

Carbon Adsorption |

TOC |

Adjunct |

|

Filtration |

TSS |

Adjunct |

|

Ultraviolet Light |

TOC and/or Bacteria |

Adjunct |

Smart wastewater recovery

Recovering wastewater for reuse within your facility — whether in the generating process or elsewhere — is often a good business decision. Matching the appropriate treatment technology with the wastewater characteristics and the desired outcome is crucial. Ion exchange is a common recovery technology for metal finishing and manufacturing wastewaters. Service-based wastewater ion exchange (WWIX) treatment uses leased, service exchange tanks. The tanks are used onsite for wastewater recovery treatment and, when spent, are replaced with fresh resin tanks with the spent tanks returned to a central processing facility for regeneration. This system relies on the customer to monitor the system for performance and to call into the service center for tank exchanges. Improving on that process and ensuring a consistent and reliable water quality is the goal of a process called Water One WX service.

The Water One WX process adds remote monitoring and data logging capability to the traditional service based WWIX system. The system monitors several key water parameters including the flowrate, feed water conductivity, and worker and polisher mixed bed resistivities. The objective is to ensure that the water quality for a process is always maintained above the minimum specifications. The system performance is monitored around the clock by a centralized control center through a wireless communications platform. When the water quality from the worker mixed bed indicates it is time for a tank change, an alarm is sent to the control center that initiates a tank exchange with the local service branch. System monitoring by the customer, and associated calls for tank exchanges, are eliminated.

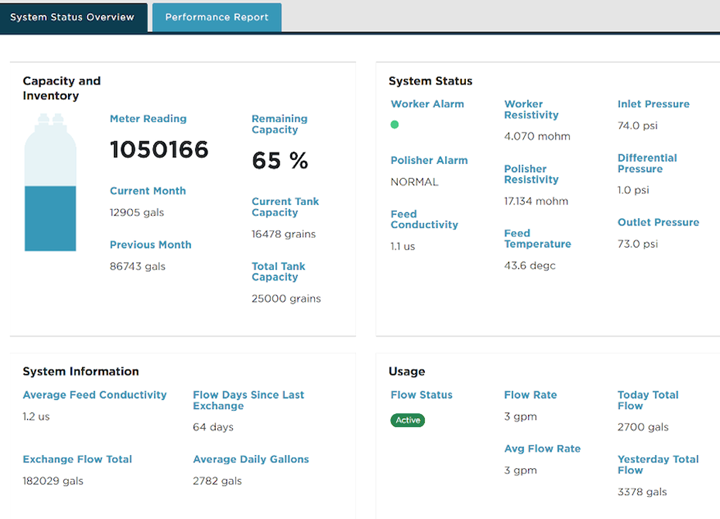

The Water One WX system uses these active system parameters to calculate average feed conductivities and average flowrates as well as to estimate the consumption of the worker mixed bed. All the historical data are stored and can be retrieved for evaluation, comparison, and reporting purposes to support customer facility audits, for example, or to assist with troubleshooting should an issue occur. Figure 1 shows a typical dashboard view of the status of the various parameters monitored.

Fig. 1. The Water One WX system uses active system parameters to calculate average feed conductivities and average flowrates as well as to estimate the consumption of the worker mixed bed. This dashboard view shows the status of various parameters monitored.

Example

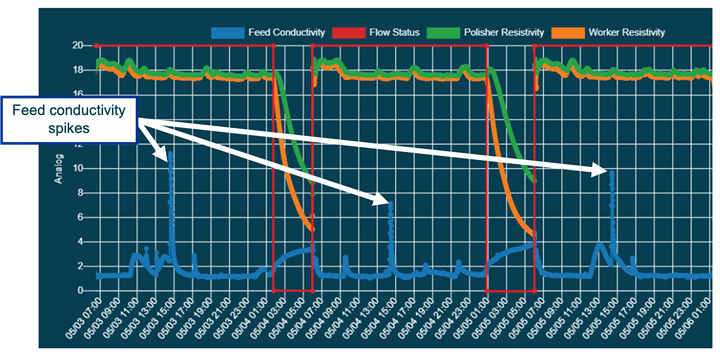

A microelectronics manufacturer, in need of high quality rinsewater for rinsing of their electronic components, installed a Water One WX wastewater recovery system consisting of pre- and post-filtration, GAC and mixed bed IX tanks. The system maintains a high water recovered quality (16+ MΩ-cm) and is monitored 24 hours per day by the Xylem Digital Command Center. The system has relieved the customer of monitoring it and arranging tank exchanges when required. Monitoring also revealed a daily conductivity spike in the feed, shown in Figure 2; further investigation identified a small, but regular, daily dump of cleaning chemistry which was eliminated enabling a more consistent feed to the IX system and optimal mixed bed tank life.

Fig. 2. The Water One WX wastewater recovery system maintains a high water recovered quality (16+ MΩ-cm) and is monitored 24 hours per day by the Xylem Digital Command Center. Monitoring also revealed a daily conductivity spike in the feed, shown here.

Metal finishing and related production processes typically generate wastewaters requiring treatment. Often, these wastewaters can be treated for recovery and reuse with ion exchange and reverse osmosis being two of the common recovery technologies employed. Coupling wastewater ion exchange with remote monitoring and data logging capabilities improves an already proven technology and results in more consistent recovered water quality while simultaneously reducing user involvement and storing historical water quality data for review when needed.

About the Author

Chris Riley

Chris Riley is the technical services director for Evoqua’s WWIX business and oversees technical support activities for customers as well as media regeneration and quality control. Chris has been with Evoqua for more than 26 years, holds a bachelor’s degree in chemical engineering from Michigan Technological University, a Master’s degree in civil (environmental) engineering from the University of Minnesota and is a registered professional engineer.

Related Content

Vacuum Degreaser Cleans Up a Messy Situation

By replacing its immersion parts washer with a vacuum degreasing system, this machine shop is much more efficient, saving the company money, man hours and the health of the operators.

Read MoreSolvent Versus Aqueous: Busting the Myths

Is aqueous cleaning “greener” than solvent cleaning? Is solvent a more effective cleaner than aqueous? These and many other questions are answered here to debunk the misconceptions that many manufacturers have held onto for years.

Read MoreTTX Environmental Solves Customer Issue with Electro-Ceramic Desalination Wastewater Processing

Electroplating facility without access to a drainage system found a safe solution for wastewater treatment and reuse.

Read More3-Stage Versus 5-Stage Washers

Columnist Rodger Talbert explains the difference between a five-stage washer and a three-stage washer, and how one provides better corrosion protection over the other.

Read MoreRead Next

Wastewater Compliance and Sustainability

A brief overview of compliance and sustainability considerations for effective wastewater treatment for finishing operations.

Read MoreImproving Wastewater Management Efficiency

Don’t find yourself underwater when managing wastewater processes. Follow these steps to improve efficiency and determine the best ROI.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More